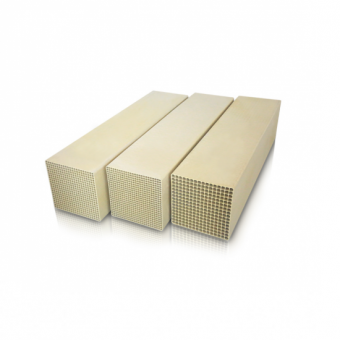

Power Station DeNOx Catalyst

Characteristics of flue gas in power industry:

1. The flue gas temperature is generally between 300-420°C.

2. The dust concentration in the flue gas can reach 10-60 g/Nm3. The dust is mostly composed of silicon, aluminum, and other particles, which can cause significant abrasion and wear on the catalyst.

3. High concentrations of sulfur dioxide in the flue gas can affect the catalyst's lifespan.

* According to the customer's requirements, we can produce different pitch and formulations of honeycomb SCR de NOx catalyst.