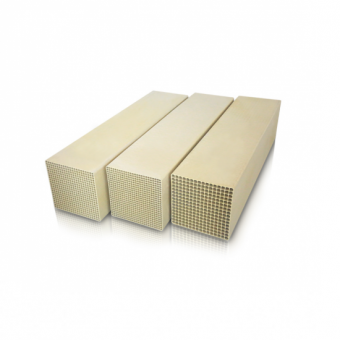

Ultra High Temperature SCR Denitration Catalyst

Main Specifications of Honeycomb Type DeNOx Catalyst:

|

Hole Number (PCS) |

Cross Section (mm) |

Hole Dia. (mm) |

Wall Thickness (mm) |

Catalyst Pitch (mm) |

Open Porosity (%) |

Specific Surface Area (m2/m3) |

Applicable Scope |

|

15×15 |

150×150 |

8.45 |

1.35 |

9.80 |

71.40 |

338 |

Coal fired unit, high smoke dust |

|

16×16 |

150×150 |

8.00 |

1.20 |

9.20 |

72.82 |

383 |

|

|

18×18 |

150×150 |

7.10 |

1.10 |

8.20 |

72.60 |

409 |

Coal fired unit, medium dust |

|

20×20 |

150×150 |

6.40 |

1.00 |

7.40 |

72.82 |

469 |

|

|

21×21 |

150×150 |

6.10 |

0.95 |

7.05 |

72.93 |

478 |

Coal fired unit, low smoke dust |

|

22×22 |

150×150 |

5.80 |

0.90 |

6.70 |

72.36 |

499 |

|

|

25×25 |

150×150 |

5.00 |

0.90 |

5.90 |

69.44 |

577 |

Coal fired unit, very low dust |

|

30×30 |

150×150 |

4.10 |

0.80 |

4.90 |

67.24 |

693 |

Oil fired unit, very low dust |

|

35×35 |

150×150 |

3.65 |

0.55 |

4.20 |

72.53 |

795 |

|

|

40×40 |

150×150 |

3.20 |

0.50 |

3.70 |

72.82 |

910 |

Natural gas fired unit |

|

45×45 |

150×150 |

2.78 |

0.50 |

3.28 |

69.56 |

1000 |

|

|

55×55 |

150×150 |

2.20 |

0.50 |

2.70 |

65.07 |

1275 |

|

|

Unit catalyst size:150×150×(length300-1350) mm. |

|||||||

* According to the customer's requirements, we can produce different pitch and formulations of honeycomb SCR de NOx catalyst.