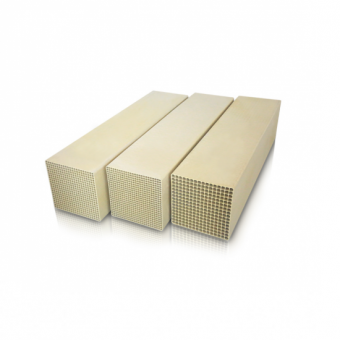

Polyimide(P84) Dust Collector Filter Bag

1.The feature Of high temperature filter bag sleeves in Thailand

P84 filter bag is a kind of flame-retardant, temperature-resistant and stable fiber filter material. Under the condition of 240℃, the mechanical of P84 polyimide fiber filter material will not change, and the highest temperature can reach 260℃. P84 fiber filter material has no melting point temperature and is natural golden yellow. P84 polyimide fiber filter material is not a hygroscopic fiber filter material (under the condition of 65% relative humidity, the water absorption is about 3%).

In addition, because the P84 fiber has a special (leaf-shaped) cross-sectional structure, it has a large filtering surface area and excellent filtering performance. Therefore, P84 fiber is often implanted on the surface of the filter material (the side of the dust facing side to improve the filtering performance of the filter material. ).

2. Physical Proerties of Industry non-woven PP PE P84 PPS PTFE NMO FMS dust collector filter bag

P84 PTFE Pulse Jet Media NOMEX Fiber Glass Dust Collector Filter Bag

Technical Specification

Name/Quality

100% P84

Component/

Shell Fiber

100% P84

Scrim

100% PTFE

Weight

500±5%gsm

Thickness

2.2±0.2mm

Air Permeability /200Pa L/dm2.min

130-180

Tensile Strength N/5*20CM

Length

≥800

Cross

≥1200

Elongation at break %

Length

≤30

Cross

≤50

Temperature ( Celsius Degree)

Continue

240

Peaks

260

Finish

Singeing, Calendering, Heat-set

Use Scope

Cement, Steel, Construction, Metallurgy,etc

3. Production Process

1)Fiber:high grade P84 fiber

2)Scrim: acrylic

3)Produce Process:needle punched

4)Filter Felt Weight: 550±20gsm

5)Filter Felt Thickness: 2.0±0.2mm

6)Finish treatment:Singeing, calendaring

7)Laboratory Testing:check the test report below

8)Cut according to customer's requirement

9)Packing according to customer's requirement

4. installation diagram

1.unpack the filter bag

2.Insert flower board hole/cell plate

3.Knead the filter bag collar

4.Align the collar with the card

5.Adjust the position of the collar

6.Align the collar to confirm position

7.Filter bag installed in place

8.Check for appropriateness

9.Finally insert the dragon skeleton/dust collector accessories filter cages

5. Application field:

P84 is mainly used in flue gas purification of asphalt mixing, cement kiln, drying, burning, smelting, various industrial kiln, coal-fired boiler and waste incineration, and is widely used in processes with high emission concentration requirements.

6. PACKAGE & DELIVERY

6.1 Filter bag standard package ways: 6.2 Inner packing:polybags 6.3 Outer packing:cartons 6.4 Other packing ways: also be accepted to meet customers' requirements

7. FRQ:

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our