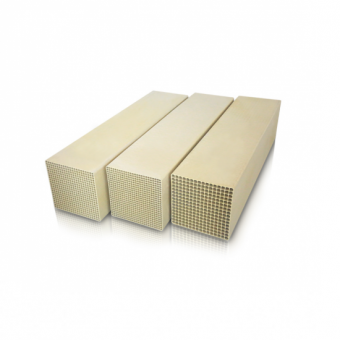

ULTRA-LOW TEMPERATURE SCR DENITRATION CATALYST

The ultra-low temperature denitrification catalyst developed by the company has good denitrification performance under low sulfur and dust conditions at 150-180°C in the ultra-low temperature section. The denitrification efficiency can reach more than 90%. It is widely used in Vaiours industries such as natural gas boilers and kilns.

LOW TEMPERATURE SCR DENITRATION CATALYST

The company's self-developed low-temperature denitration catalyst adopts advanced production technology. The catalyst has very good denitration performance in the low temperature section (180-280 °C), it can process high concentration of nitrogen oxides, and the denitration efficiency is over 95%. Low-temperature denitration catalysts are widely used in coking plants, sintering machines, small industrial boilers, industrial furnaces, glass and other industries.

MEDIUM TEMPERATURE SCR DENITRATION CATALYST

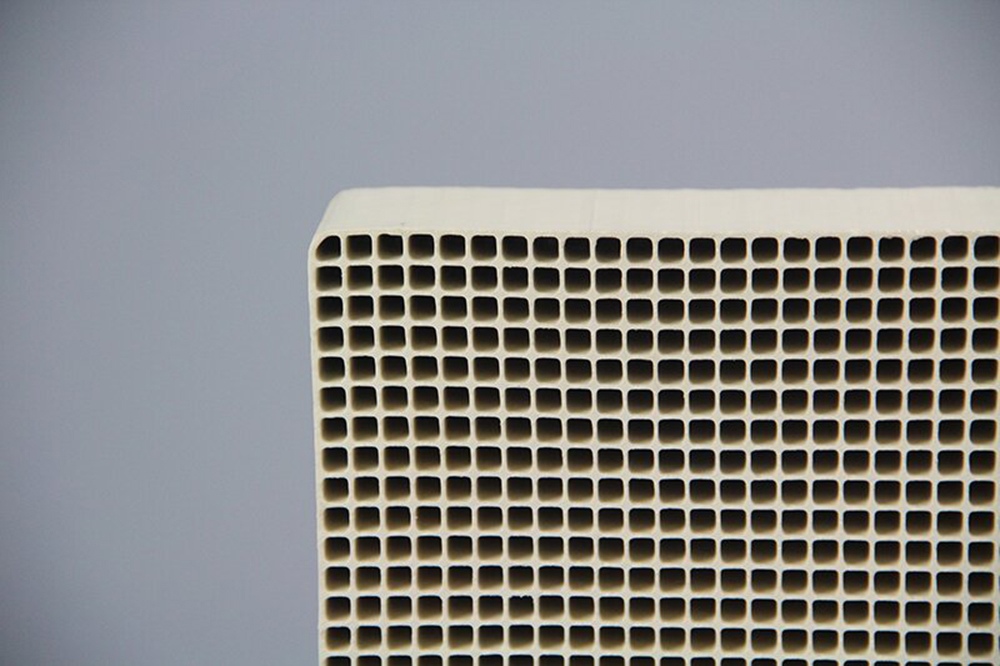

This type adopts a front-end hardening process, increase the wear-resistant coating and maintain a long mechanical life. The raw material is made of high quality anatase titanium dioxide with large specific surface area. It is optimized for the flue gas environment of various industries and has strong anti-poisoning ability. The product design can be carried out for different flue gas conditions, with strong pertinence and excellent product performance. Widely used in power plant boilers, industrial boilers and other industries, to adapt to temperature range of 280-420°C.

HIGH TEMPERATURE SCR DENITRATION CATALYST

This type adopts international advanced technology and high-quality cordierite catalyst carrier. Coating composite molecular sieve catalyst, to improve the activity and stability of the catalyst at high temperature. It can be widely used in 300-550°C working conditions, and can be customized according to different industry conditions. It is commonly used in various high-temperature flue gas fields such as gas kiln and diesel engine.

We manufacture catalyst in a number of different pitched.The choice of pitch is optimized after the study of the flue gas composition and the allowable pressure drop across the SCR reactor.

Typical industrial applications:

It is widely used inthermal power plants, coal-fired power plants, waste incineration plants, steel plants, fertilizer plants, nitric acid plants, cement plants, petrochemical chemical plants and other all industrial which need to reduce the NOx emissions, also used in diesel engines tail gas treatment etc..

Main specifications & technical index of honeycomb SCR catalyst:

|

Hole Number (PCS) |

Cross Section (mm) |

Hole Dia. (mm) |

Wall Thickness (mm) |

Catalyst Pitch (mm) |

Open Porosity (%) |

Specific Surface Area (m2/m3) |

Applicable Scope |

|

15×15 |

150×150 |

8.45 |

1.35 |

9.80 |

71.40 |

338 |

Coal fired unit, high smoke dust |

|

16×16 |

150×150 |

8.00 |

1.20 |

9.20 |

72.82 |

383 |

|

|

18×18 |

150×150 |

7.10 |

1.10 |

8.20 |

72.60 |

409 |

Coal fired unit, medium dust |

|

20×20 |

150×150 |

6.40 |

1.00 |

7.40 |

72.82 |

469 |

|

|

21×21 |

150×150 |

6.10 |

0.95 |

7.05 |

72.93 |

478 |

Coal fired unit, low smoke dust |

|

22×22 |

150×150 |

5.80 |

0.90 |

6.70 |

72.36 |

499 |

|

|

25×25 |

150×150 |

5.00 |

0.90 |

5.90 |

69.44 |

577 |

Coal fired unit, very low dust |

|

30×30 |

150×150 |

4.10 |

0.80 |

4.90 |

67.24 |

693 |

Oil fired unit, very low dust |

|

35×35 |

150×150 |

3.65 |

0.55 |

4.20 |

72.53 |

795 |

|

|

40×40 |

150×150 |

3.20 |

0.50 |

3.70 |

72.82 |

910 |

Natural gas fired unit |

|

45×45 |

150×150 |

2.78 |

0.50 |

3.28 |

69.56 |

1000 |

|

|

55×55 |

150×150 |

2.20 |

0.50 |

2.70 |

65.07 |

1275 |

|

|

Unit catalyst size:150×150×(length300-1350) mm. |

|||||||

According to the customer's requirements, we can produce different pitch and formulations of honeycomb SCR de NOx catalyst.

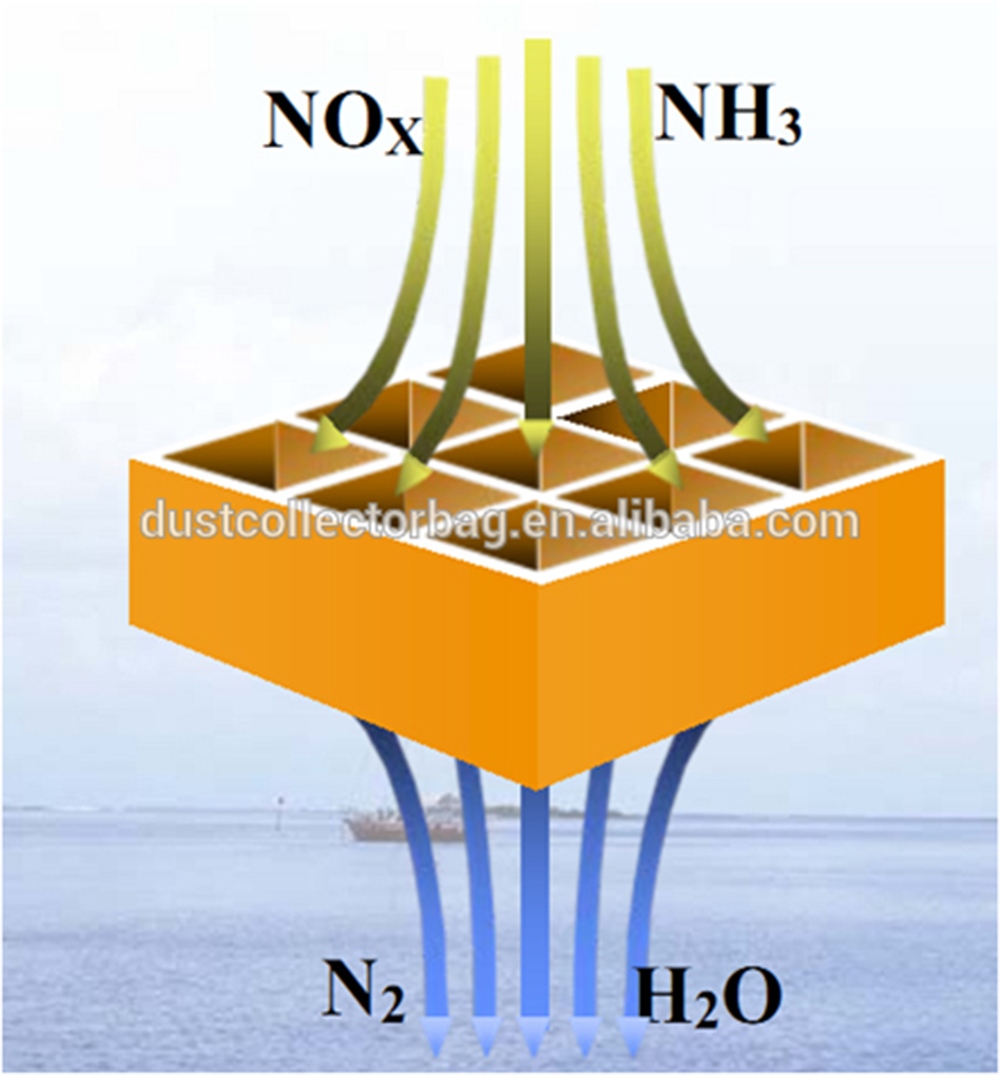

Technology Introduction

SCR technology is a reaction at use of the denitration catalyst at a certain temperature (270-400℃),that NOX in the flue gas mixed with ammonia gas from the reducing agent supply system after the occurrence of the selective catalytic reduction reaction of nitrogen and water ,thereby reducing NOx emissions,and reducing smoke pollution to the environment .

Several reductants are currently used in SCR applications including anhydrous ammonia,aqueous ammonia(25%NH3)or use.Typical SCR system consist of anhydrous ammonia storage &transportation (using anhydrous ammonia as the reductant )evaporator ,AIG and mixer,flue gas system ,reactor and ammonia emergency management system.

Reaction:

4NO+4NH3+O2→4N2+6H2O, 2NO2+4NH3+O2→3N2+6H2O

The honeycomb SCR catalyst packaging

Carton box to pallet, wooden case or as per customer's requirements.

Certification:we passed ISO9001 ,ISO4001, SGS,CNAS and others

After Sale Service

1.OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry within 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

5.Quality Guarantee, If there have any quality problems with products, we are willing to be replaced free.

6.rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours.If any problem, We will arrange professional engineers within 48 working hours to solve it.

7. All goods will be inspected and tested before shipment.

Customer’s satisfactory is most important to us. If you have any problems about our products. Please feel free to contact us with any comments you may have;

FAQ

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:We keep good quality and competitive price to ensure our customers benefit