Polyester filter bag for cement industry baghouse

1. Features Of Industrial Polyester Filter Bag for Dust Collection

1.High efficient filtration level

2.Depth type filtration

3.Wide range of chemically compatible media

4.High temperature resistance

5.High flow efficiency

6.High air to cloth ratio

7.Various coatings are available

2. We pay attention to following processing matters:

(1) Precise design required size of the filter cloth for filter bag parts, the filter cloth will larger than the actual amount design size, to leave a spare for weaving.

(2) To choose the right filter bag accessories, specifications and check its quality. The filter bag accessories should match the filter bag quality requirements.

(3) We make the filter bag line drawing, cutting, sewing on automatic production line. When the filter bag need manual processing, we will open it on the operation platform, and with certain pulling force to keep it is flat.

(4) We keep the strict processing quality standards, according to design drawings and operation process. Our worker meet the requirements of tooling and clothing , no smoking.

(5) We have the responsible for the processing of products, and examines, waste, residue, defective goods in the beginning.

Technical Specification

Name/Quality

100% PE

Component

Shell Fiber

100% PE

Scrim

100% PE filament fiber

Weight

550gsm±5%

Thickness

1.9mm ± 0.2

Air Permeability /200 Pa L/dm2.min

20-50

Tensile Strength N/5*20CM

Length

≥1000

Cross

≥1500

Elongation at break %

Length

≤30

Cross

≤50

Temperature ( Celsius Degree)

Continue

130

Peaks

150

Finish

Singeing, Calendering, Heat-set, PTFE Membrane

Use Scope

Cement, Steel, Construction, Metallurgy

3. Remarks for industrial dust collector bags

1) The length of dust filter bags: can be customized

Usual size: diameter 100mm, 125mm, 130mm, 150mm, 180mm, 250mm ect.

2) Process Method: automatic sewing or welded

3) Prodction details:Double bottoms and reinforcement to make abrasion resistance.

Sewing thread: PTFE thread, polyester thread.

4) Inspection: Filter bags will be according to the national standards, industry standards and enterprise standards.

5) If your required filter bag is different from our usual one, then please send us your drawing picture and choose material you need since we also produce the nonstandard filter bag.

4.Finish Treatment of cement dust collector bags

Singeing, Calendering, Heat Setting, Anti-static, Water&Oil Repellent, PTFE Membrane, PTFE Impregnation and so on special treatment can be chosen.

5. Application for Polyester/PE Needle Punched Felt Filter Bag Sleeves:

* Asphalt – Durable construction required for abrasive, high temp environments. Hotmix or batch plants, whether natural gas, waste oil, fuel oil, etc.

* Cement – Filters for all areas of plant: kilns bag houses, silo bin vents, nuisance dust collection, etc. Our filters exceed all EPA emissions standards (NESHAP, CMAT, MACT for portland cement, PM2.5, etc.).

* Chemical – Filter fabrics for acidic or alkali compounds, corrosive or abrasive elements, etc. (lime, calc, fertilizer, plastics, etc.) – Special treatments and fabrics available. We can advise on the best combination for performance and cost.

* Food Processing – Food-grade fabrics construction available for dust collectors used in food production, transportation and packaging such as dust collectors on milling equipment, blenders, mixers, granulators, grain elevators, storage silos and more.

* Foundry and Metal Products – Filters for units used on arc/induction furnaces, casting operations, and precious metal reclamation. Fabrics and coatings for use in high temperature environments with need for high efficiency fume and smoke .* Power Generation and Industrial Boilers – Our filters exceed new EPA emissions regulations for boilers and power generation (Mercury and Air Toxics, Boiler MACT, NESHAPs, etc.). We have much experience working with biomass and coal power production facilities to overcome technical challenges to meet new EPA regulations. Filter fabrics and treatments include PPS, P84, PTFE/Teflon (fabric), fiberglass, and ePTFE membrane.

6. The YUANCHEN cloth filter bags packaging:

Different types of filter bag must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. Filter bag must be neat and regular packing, with the ring of the filter bag to avoid ring flat compression deformation. For the requirement to keep the shape of filter bag, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

7. FRQ:

1). Are you a manufacturer or trading company?

Manufacturer which located in Hefei,Anhui,China

2). What are your main products?

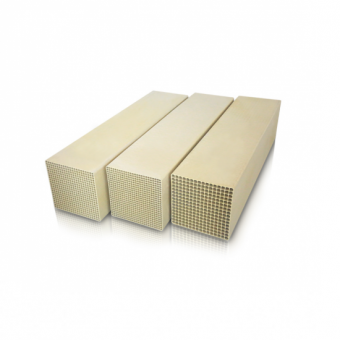

Needle punched felt, Dust filter bags, SCR Honeycomb Catalyst

3).What payment method can you do?

T/T L/C PAYPAL WESTERN UNION

4). What size can you do?

Customized sizes as you required.

5). Can you offer a sample before an order?

Yes, and it is a free sample

6). How can I order from you?

Step 1 You make the deposit after the Proforma Invoice finalized

Step 2 We start the production, and keep the communication with you if any questions

Step 3 You make the rest payment when the cargo is ready to ship

Step 4 We ship out the cargo, then offer documents