New Style Nonwoven Nomex Dust Collector Filter Bag / Filter Sleeve

Product Description

Nomex Needle Felt Dust Filter sleeves adopt optimized technology to improve various physical and chemical properties of the product and make the application better.

Nomex Needle Felt Dust Filter socks can be operated continuously at a temperature of 204°C (instant temperature 250°C) and can withstand repeated 250°C instantaneous temperature fluctuations. At the same time, it has outstanding dimensional stability. At a temperature of 250°C, it is only less than 1% heat shrinkage rate, high temperature stability of Nomex Needle Felt Dust Filter Bag. Nomex Needle Felt Dust Filter Bag has good chemical resistance. Low concentrations of acids and alkalis and most hydrocarbons will not affect it, and even a small amount of fluoride will not corrode it significantly.

Product Parameter

|

Technical Specification |

||

|

Name/Quality |

100% Nomex |

|

|

Component |

Shell Fiber |

100% Nomex |

|

|

Scrim |

PTFE |

|

Weight |

500±5%gsm |

|

|

Thickness |

2.0±0.2mm |

|

|

Air Permeability /200Pa L/dm2.min |

130-180 |

|

|

Tensile Strength N/5*20CM |

Length |

≥800 |

|

|

Cross |

≥1200 |

|

Elongation at break% |

Length |

≤30 |

|

|

Cross |

≤50 |

|

Temperature ℃ |

Continue |

200 |

|

|

Peaks |

220 |

|

Finish |

Singeing,Calendering,Heat-set |

|

|

Use Scope |

Cement, Steel, Construction,Metallurgy, etc |

|

Feature

1. Excellent temperature resistance: It can be operated continuously at a temperature of 204°C (an instantaneous temperature of 250°C), and can withstand repeated instantaneous temperature fluctuations of 250°C.

2. Good chemical resistance: low concentration of acid and alkali and most hydrocarbons will not affect it, even a small amount of fluoride will not corrode obviously.

3. Outstanding dimensional stability: only less than 1% thermal shrinkage rate at 250℃, with high temperature stability.

4. Proud fire resistance: it starts to decompose and carbonize at 400℃, and its oxygen index is 30. It does not spontaneously combust or support combustion.

Post-treatment introduction

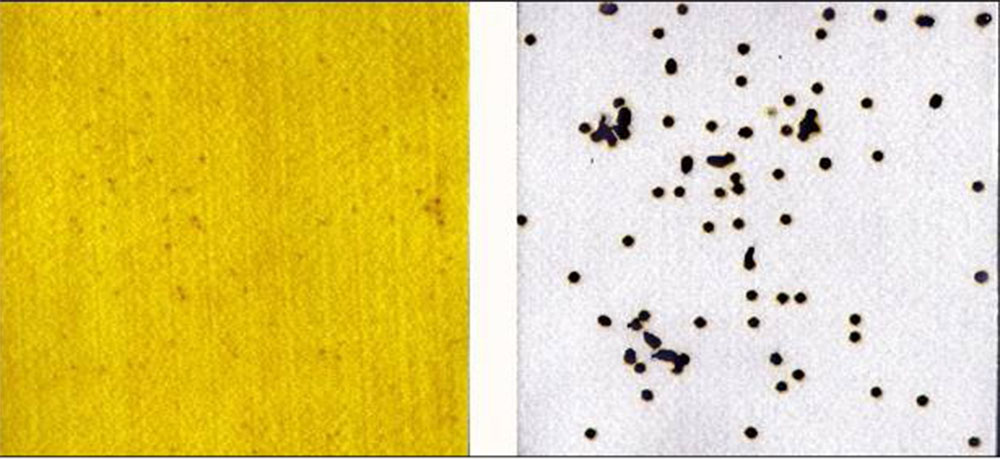

Burning and Pressing Treatment

The imported burning and pressing equipment and the treated needle felt filter material has the unparalleled advantages of ordinary singeing and calendering treatment on one side and double side, which not only improves the cleaning performance of the filter material, but also meets the collection of fine dust.

Some dusts will burn when it encounters a spark at a specific concentration. Therefore, anti-static treated needled felt filter media should be used for flammable and explosive dust. Antistatic filter material refers to mixing conductive fiber (including binary conductive fiber, graphite conductive fiber and stainless steel conductive fiber) into the filter material fiber, so that the whole filter material has conductive properties.

Water-Proof and Oil-Proof Treatment

The oil-proof and water-proof treatment of fluorocarbon resin and PTFE impregnation is adopted for the needled felt filter material, which is easier to collect dust on the surface of the filter bag of wet dust containing gas (especially for water-absorbing and deliquescent dust), avoiding and reducing the phenomenon of pasting bag.

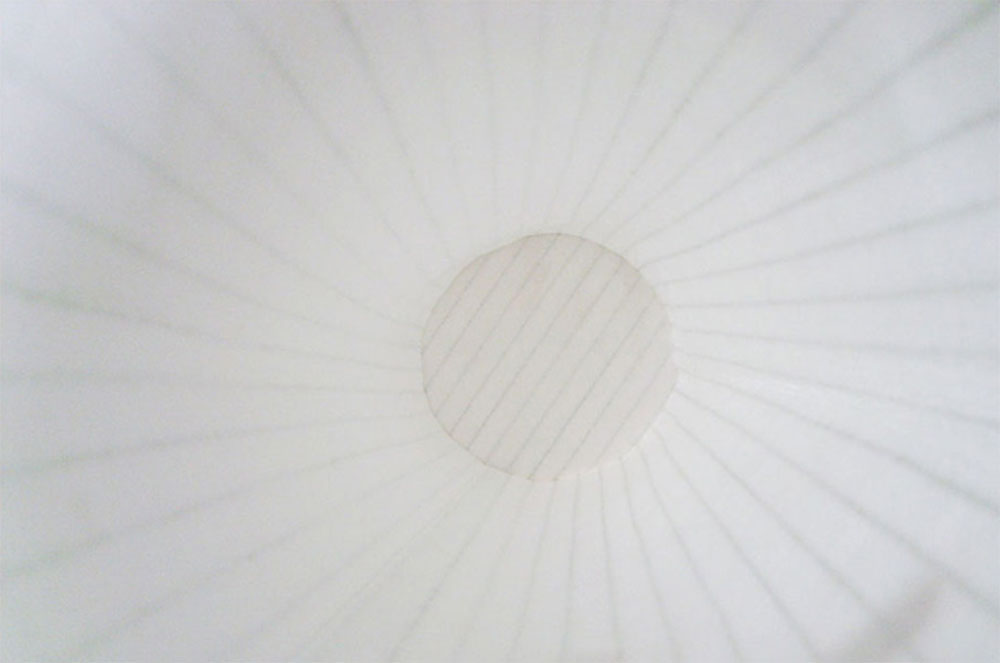

PTFE Membrane Treatment

When the particle size of dust is less than 1 micron, or the dust has a large viscosity, or the humidity of the gas is large, the ordinary filter material can not effectively filter. The membrane filter material made of polytetrafluoroethylene (Teflon®) has high filtration precision, smooth surface, no adhesion to dust. It’s easy to clean dust and the dust does not penetrate into the filter material achieving surface filtration.

Can be widely used in the field of high temperature filtration, long-term use can maintain high strength and high performance; used in asphalt, cement, steel, non-ferrous metals, lime, dust, metallurgy, drying, gravel, gypsum, plastic, carbon black, coke, Shipbuilding, tobacco and other industries.

The High Filtration Nomex /Aramid Dust Filter Bag in Steel Industry Packaging:

Different types of bag filter cloth sock sleeves must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. stainless steel snap band Filter bag with the diameter of cell plate 135mm must be neat and regular packing, with the ring of the filter bag(whatever stainless steel or carbon material) to avoid ring flat compression deformation. For the requirement to keep the shape of filter bag, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

7. FRQ:

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.

Generally, It will take 10 to 20 days after receiving your advanced payment. The specific delivery time depends on your items and quantity of your order.