Polyimide Dust Bags Material Filter Cloth

1.Brief Introduction Of Polyimide Dust Filter Cloth

P84 (PI-polyimide) is a filter material with the properties of flame resistance, high temperature resistance.

Polyimide will keep a good performance when the temperatures up to 240 degree centigrade, instant can

up to 260 degree to 300 degree. Polyimide is leaf-shaped structure with a larger filter surface, and always

embedded in the surface of other needle felt with different material to improve the filter efficiency. For the

properties of high Temperature resistant filter material, good chemical resistance, good air permeability,

high filtration efficiency, mostly applied in Cement kiln, Asphalt, Waster Incinerator, coal boilers, etc.

2.Technical Data:

|

Technical Specification |

||

|

Name/Quality |

100% P84 |

|

|

Component |

Shell Fiber |

100% P84 |

|

|

Scrim |

100% PTFE |

|

Weight |

500±5% gsm |

|

|

Thickness |

2.2±0.2mm |

|

|

Air Permeability /200Pa L/dm2.min |

130-180 |

|

|

Tensile Strength N/5*20CM |

Length |

≥800 |

|

|

Cross |

≥1200 |

|

Elongation at break % |

Length |

≤30 |

|

|

Cross |

≤50 |

|

Temperature ( Celsius Degree) |

Continue |

240 |

|

|

Peaks |

260 |

|

Finish |

Singeing, Calendering, Heat-set |

|

|

Use Scope |

Cement, Steel, Construction, Metallurgy |

|

3.Requirements for the selection of dust collection bag

One of the most important factors in the question of whether it is customized or ready-made is the processing requirements. For example, if exhaust gas must contain particulate pollutants below a certain threshold, and you choose to use an off-the-shelf solution, it may not meet these requirements.

Requirements may include: requirements for prohibiting the use of silica dust, requirements for the removal of explosive dust and particulate matter such as flour, and prohibitions on the discharge of heavy metals, toxic gases and environmental pollutants into the air. These may require specialized filters, airflow patterns, physical space limitations, and other considerations that many off-the-shelf systems may not be able to accommodate.

4.Advantages of the product:

1.Various material: Polyester(PE), Polypropylen(PP), Aramid, P84, Acrylic, PPS, Fiberglass, PTFE,Nomex,FMS etc.

2.Strong intensity

3.Excellent anti-abrasion,good finishing treatment

4.Good raw material, competitive price

5.High filtration efficiency

6.Fast delivery

7.Size can be customized

8.Factory manufacturer could contal quality and price

9.Strict quality inspection and contol

10.Professional designer teams to match with your operating condition

5.Unusual application of dust collector filter bag

In industry dust collection

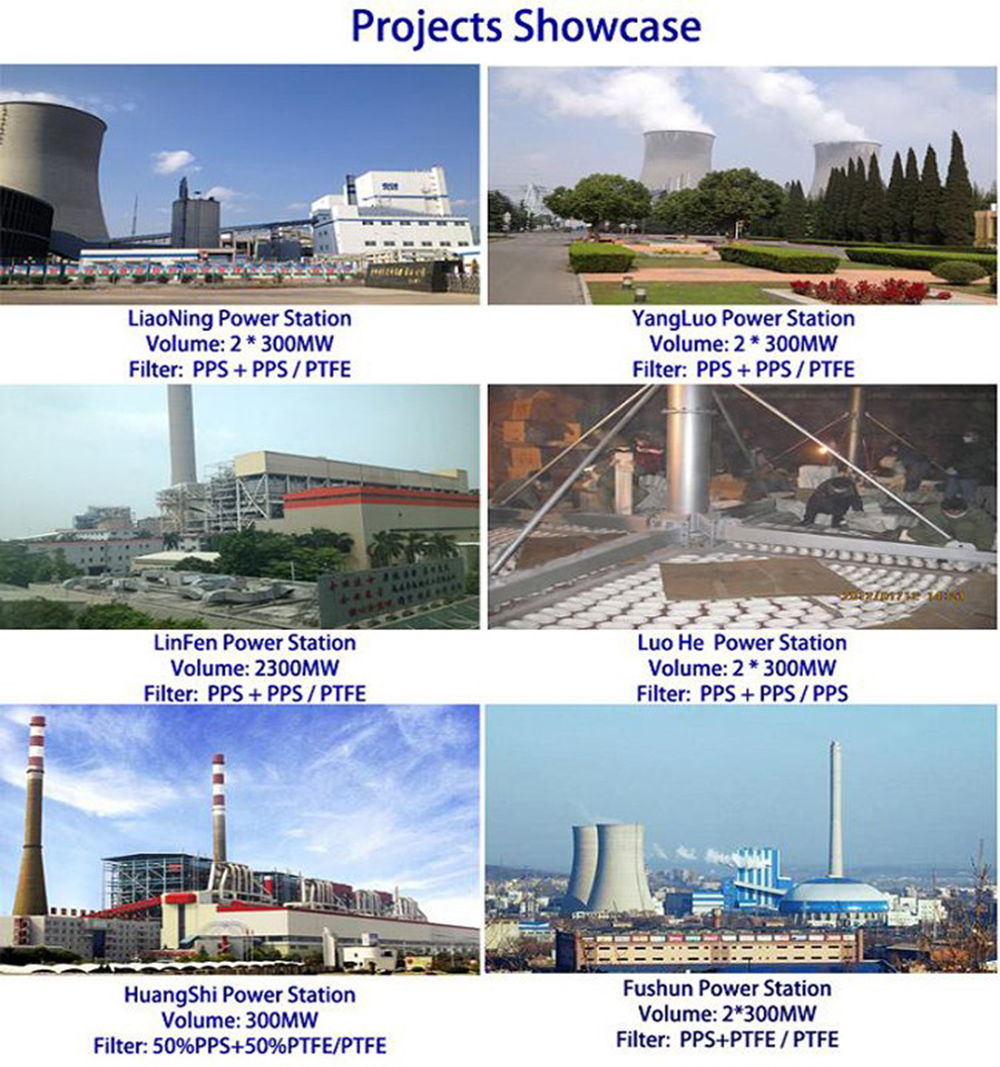

. Power Offer Or Stations

Filtered dust, waste incineration, Flue ash, discharging flue ash ,Coal dust

. Building and Construction

Cement, iron and steel ,furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals, Pure clay, phosphates, magnesite concentrate, finely ground ,fluorid, production of aluminum

. Chemical Industry

Thomas meal (Fertilizer) ,Rubber compounds, sinter dust, catalysts ,Sodium sulfate

Soap powder

In machinery top:

Silos/Tanks,Discharging systems,Warehouse units ,Mixing equipment ,Homogenizing systems,Chute Bottoms,Conveyor systems,Ventilator systems,Aeration systems ,Powder Coating Machinery ,Bottoms for sinter basin

6.Packaging&Delivery

Package

Different types of filter bag must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. Filter bag must be neat and regular packing, with the ring of the filter bag to avoid ring flat compression deformation. For the requirement to keep the shape of filter bag, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

|

Polyimide Dust Filter Cloth |

100m*2.2m |

150m*2.2m |

|

Weight |

120kgs |

180kgs |

|

Packing size |

2.22m*0.45m*0.45m |

2.22m*0.65m*0.65m |

|

Volume /Roll |

0.45m3 |

0.94m3 |

Delivery

|

Polyimide Dust Filter Cloth |

20GP |

40GP |

40 HQ |

|

Quantity |

13000 m2 |

24000 m2 |

30000 m2 |

7.FRQ

Q1: Wonder if you accept small orders?

A1: Do not worry. Feel free to contact us .in order to get more orders and give our clients more convener ,we accept small order.

Q2: Can you send products to my country?

A2: Sure, we can. If you do not have your own ship forwarder, we can help you.

Q3: Can you do OEM for me?

A3: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you ASAP.

Q4: What's your payment terms ?

A4: By T/T,LCATSIGHT,30% deposit in advance, balance 70% before shipment. Or other payment terms we can negotiate with each other.

Q5: How can I place the order?

A5: First sign the PI,pay deposit,then we will arrange the production.After finished production need you pay balance. Finally we will ship the Goods.

Q6: When can I get the quotation ?

A6: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or tell us in your mail, so that we could regard your inquiry priority.