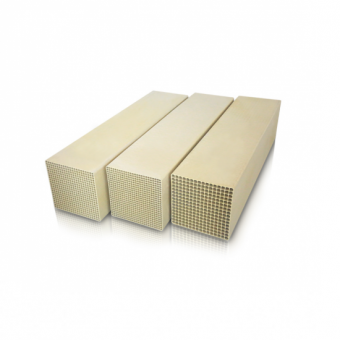

Factory direct sale New Custom High Temperature Resistant PTFE Laminating Dust Collector Filter Bags

1. The influence of the moisture content in the air on the PTFE dust filter bag

When the moisture content in the air is constant and the temperature of the humid air is lower than the dew point temperature, moisture will precipitate in the supersaturated air, that is, condensation will occur in the dust bag; when the air temperature is higher than the dew point, no moisture will be precipitated. There will be no condensation. In addition, if the flue gas contains SO2, the more SO2 content, the higher the dew point of the flue gas

2.Measures to extend the life of filter bags

1. Appropriate filtering wind speed

Generally, when the dust concentration is high, the wind speed of the filter should be lower, and vice versa. The smaller the dust particles, the lower the wind speed of the filter, and vice versa.

2. Pre-spray to prevent oil adhesion

When the boiler is ignited and operating under low load, it usually takes a long time to drain the oil. If the filter bag is not pre-treated when the oil fume passes through the filter bag, it will cause irreversible damage to the filter bag.

3. Correct injection pressure and pulse width

Adjust the appropriate blowing pressure and pulse width to avoid excessive blowing pressure.

4. Suitable exhaust temperature

Strictly control the change of exhaust temperature to prevent it from being too high or too low.

5. Temperature indicators

The filter material can be divided into normal temperature filter material, medium temperature filter material and high temperature filter material according to the amount of temperature it withstands. Generally speaking, the high temperature that can withstand is about 200℃~300℃, and the temperature tolerance of the glass fiber filter material is 300℃, but the working temperature should be controlled at about 260℃.

3. Certificate available

• Hazardous waste management license

• Environmental management system certification

ISO14001:2004

ISO9001:2008

OHSAS18001:2007

• CNAS Laboratory

• CE Certificat

4.Raw Material Test

We yuanchen have our own lab for test raw material of needle punched felts

5. Application field:

Yuanchen products are widely used in purifying dusty air in industries like Metallurgy, Steel, Cement, Mechanical, Electricity, Chemicals, Waste Incineration, Concrete Mixing and Other conditions of complex industries.

Yuanchen pulse jet dust Filter Bags are sold very well both domestic and abroad, highly praised by our customers.

We can supply you with the product in large quantity at wholesale prices.

And best after-sales service provided after order confirmed.

6. The Asphalt Plant Dust Collector Aramid PTFE Filter Bags packaging:

Different types of dust collection filter bags must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. Dust Bag Filter must be neat and regular packing, with the ring of the waste incineration dust filter bag to avoid ring flat compression deformation. For the requirement to keep the shape of cloth dust collector filter bag, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

7.Advantages

1.careful lathe stitching-the lathe sealing edge three locks,not off-line line

2.high quality material-the fiber has high strength,high stability and high heat resistance

3.sweet custom-can be customized,can be coated,high temperature resistance

4.thickness is optional-different thickness can be made according to customer's requirements