Customized Cement Kiln Dust PPS PTFE Filter Bag for Dust Collector High Temperature Resistance Matching Bag Filter Cage

1. Product Description

The PPS fiber used in the PPS dust filter sleeve is also called polyphenylene sulfide fiber. Due to its special molecular structure, it has good chemical stability and strength and maintains its characteristics. It is especially effective in the flue gas environment with high sulfur content. It is suitable for high-acid flue gas filtration environment such as coal-fired boilers, electric power, and garbage incineration. The dust filter bag is the heart of the bag filter. During the operation of the bag filter, the cylindrical pulse filter bag is suspended vertically in the dust collector. The dust-containing gas enters the dust collector from the air inlet and passes through the baffle of the ash bucket. Part of the large particle dust in the gas is separated by the inertial force and falls directly into the ash bucket. The dust-containing gas enters the filter sock filtration zone of the tank, and most of the dust is trapped on the outer surface of the filter bag, and is clean. The gas enters the inside of the filter sleeves through the filter material, and the purified gas enters the upper tank through the filter bag mouth, and then is discharged from the air outlet. The cage inside the filter bag is used to support the filter socks to prevent the filter bag from collapsing, and it helps to remove and redistribute the dust cake.

The total installed capacity of the power industry is 83890MW, with a service life of more than 5 years,and the capacity for dust collection filter bag is 3500pcs /day

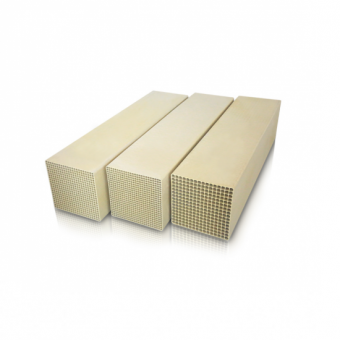

2. Technical Specification of industrial filter sleeves

1)Materials: PPS needle punched felt

2)Weight: 550±5% gsm

3)Thickness: 1.7±0.2mm

4)Usage: Air Filtration,Powder filtration,Metal collection,Dust Collector,Baghouse

5)Application:Coal-fired boilers, flue gas purification in waste incinerators, coke ovens, kilns and chemical drying,carbon black powder capture, pneumatic transport, chemistry, cement,power etc.,

3. Application field:

It is suitable for chemical industry, asphalt mixing, blast furnace coal gas, coal-fired boiler, waste incineration, metal smelting, and other low oxidation flue gas dust collection in coking industry.

4. Packaging:

Different types of filter bag must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. Filter bag must be neat and regular packing, with the ring of the filter bag to avoid ring flat compression deformation. For the requirement to keep the shape of filter sock, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

5. FRQ:

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.