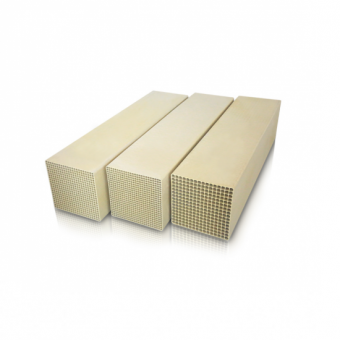

550GSM Nomex and PTFE china dust collector filter bag

Product Description

Aramid bag

Aramid (commonly known as aromatic polyamide fiber) has long-term temperature resistance of 204°C and instantaneous temperature resistance of 240°C. It has strong alkali resistance and medium acid resistance. It is a good material for handling high temperature gases at 180-220°C.

|

Technical Specification |

||

|

Name/Quality |

100% Nomex |

|

|

Component |

Shell Fiber |

100% Nomex |

|

|

Scrim |

PTFE |

|

Weight |

500±5%gsm |

|

|

Thickness |

2.0±0.2mm |

|

|

Air Permeability /200Pa L/dm2.min |

130-180 |

|

|

Tensile Strength N/5*20CM |

Length |

≥800 |

|

|

Cross |

≥1200 |

|

Elongation at break% |

Length |

≤30 |

|

|

Cross |

≤50 |

|

Temperature ℃ |

Continue |

200 |

|

|

Peaks |

220 |

|

Finish |

Singeing,Calendering,Heat-set |

|

|

Use Scope |

Cement, Steel, Construction,Metallurgy, etc |

|

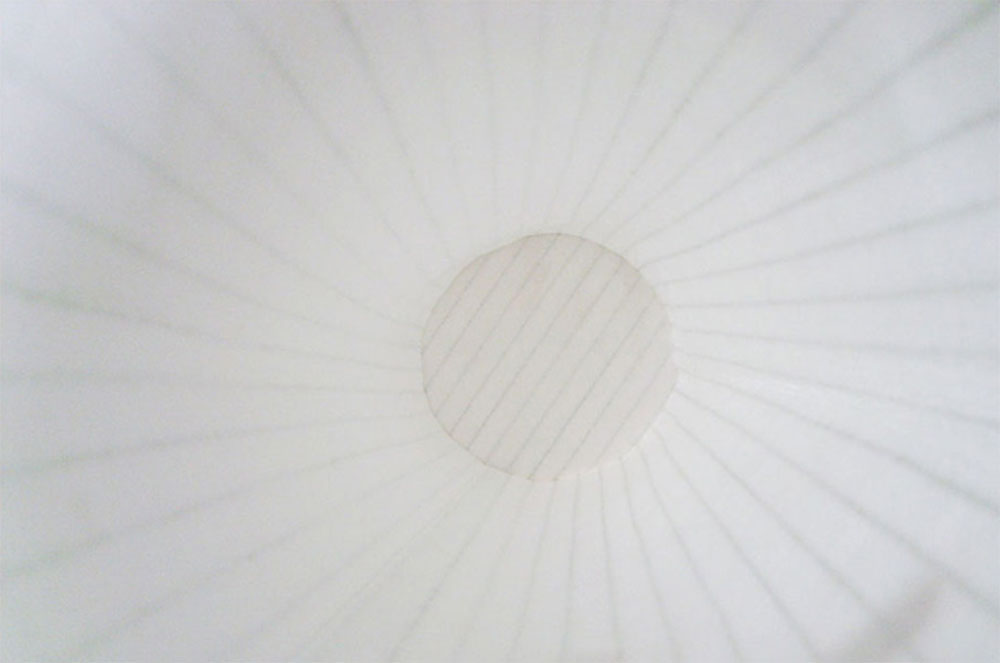

How to install the nomex needle-punched filter bag?

1) New technology and old nomex dust filter bag in steel industry should not be mixed to avoid the difference in damage time from affecting the normal operation of the dust removal equipment.

2) The aging of high temperature industrial dust bag filter. Mainly due to the following reasons, it is necessary to investigate the cause, take elimination measures and replace the dust filter bag. ①It hardens and shrinks due to abnormal high temperature; ②Reacts due to contact with acid, alkali or organic solvent vapor; ③Reacts with moisture.

3) The non woven industrial filter cloth should not be hung too loosely or tightly. Too loose and easy to accumulate dust, and too tight to be easily damaged.

4) After replacing the dust collector filter sleeve, blow it with compressed air first, and then check for any holes. After the holes are repaired, they will be kept for replacement. If the cloth bag is stuck with dust, wash it with water, and leave it to be replaced after it has dried.

5) The clogging of the dust filter bags. When the cloth filter bag is clogged, the resistance increases, which can be reflected by the increase in the reading of the differential pressure gauge. The clogging of the cloth bag is the main reason for the phenomenon of cloth bag wear, perforation, falling off and so on. For the cause of the clogging of the dust bag, check and repair according to the following table. Generally, the following measures are taken: ①Temporarily strengthen dust removal to eliminate the clogging of the cloth bag; ②Partially or completely replace the cloth dust collection filter bag with snap ring; ③Adjust the installation and operating conditions.

Post-treatment introduction

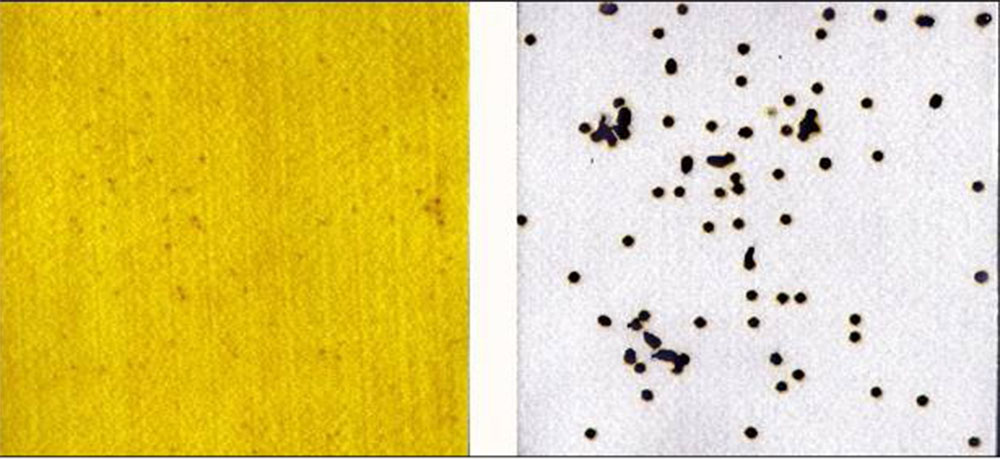

Burning and Pressing Treatment

The imported burning and pressing equipment and the treated needle felt filter material has the unparalleled advantages of ordinary singeing and calendering treatment on one side and double side, which not only improves the cleaning performance of the filter material, but also meets the collection of fine dust.

Some dusts will burn when it encounters a spark at a specific concentration. Therefore, anti-static treated needled felt filter media should be used for flammable and explosive dust. Antistatic filter material refers to mixing conductive fiber (including binary conductive fiber, graphite conductive fiber and stainless steel conductive fiber) into the filter material fiber, so that the whole filter material has conductive properties.

Water-Proof and Oil-Proof Treatment

The oil-proof and water-proof treatment of fluorocarbon resin and PTFE impregnation is adopted for the needled felt filter material, which is easier to collect dust on the surface of the filter bag of wet dust containing gas (especially for water-absorbing and deliquescent dust), avoiding and reducing the phenomenon of pasting bag.

PTFE Membrane Treatment

When the particle size of dust is less than 1 micron, or the dust has a large viscosity, or the humidity of the gas is large, the ordinary filter material can not effectively filter. The membrane filter material made of polytetrafluoroethylene (Teflon®) has high filtration precision, smooth surface, no adhesion to dust. It’s easy to clean dust and the dust does not penetrate into the filter material achieving surface filtration.

Flue gas treatment and dust removal systems in ironworks, steelworks, ferroalloy plants, refractory plants, foundries, power plants, etc.

Waste incinerators, coal-fired boilers, fluidized bed boilers and other flue gas filtration.

Asphalt concrete mixing, building materials, cement ceramics, lime, gypsum and other production sites.

Smelting flue gas filtration of aluminum electrolysis, lead, tin, zinc, copper and other rare metals, recovery of fine materials, separation of liquid and solid.

Liquid-solid separation and fine material recovery in the fields of chemicals, coke, carbon black, dyes, pharmaceuticals, plastics, etc.

Dust treatment and purification collection in mining, grain processing, flour, electronics industry, wood processing, etc.

PPS Filter Felt Bag Packaging:

Different types of high temperature filter bags must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. stainless steel snap band Filter bag with the diameter of cell plate 135mm must be neat and regular packing, with the ring of the filter bag(whatever stainless steel or carbon material) to avoid ring flat compression deformation. For the requirement to keep the shape of filter bag, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

7. FRQ:

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.

Generally, It will take 10 to 20 days after receiving your advanced payment. The specific delivery time depends on your items and quantity of your order.