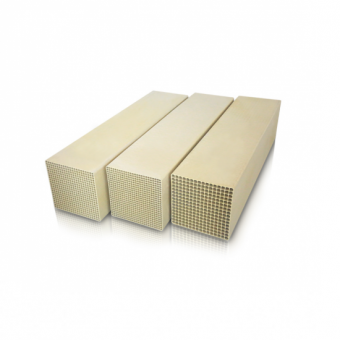

PPS PTFE Composite Filter Bag

Brief Introduction of PPS PTFE Composite Filter Bag:

1. High-Temperature Resistance: The PPS material provides exceptional resistance to high temperatures, making the filter bag suitable for applications in power plants and steel plants.

2. Excellent Chemical Resistance: The PPS PTFE composite filter bag offers excellent resistance to acids, alkalis, and corrosive gases, ensuring reliable performance in challenging environments.

3. Enhanced Filtration Efficiency: The PTFE coating on the filter bag improves filtration efficiency by capturing fine particles and maintaining cleaner air quality.

4. Superior Mechanical Strength: The combination of PPS and PTFE materials ensures the filter bag's durability, dimensional stability, and resistance to abrasion.

5. Long Service Life: The PPS PTFE composite filter bag has an extended service life, reducing maintenance and replacement costs.

6. Reduced Bag Cleaning Frequency: The PTFE coating allows for easy dust cake release, reducing the frequency of bag cleaning and optimizing filtration efficiency.

7. Versatile Applications: This filter bag is ideal for power plants and steel plants, where high-temperature and aggressive filtration conditions are present.

Yuanchen Advantages:

1. Huge production scale: +500 employees, productivity: +20000㎡ filter cloth (+4000 pcs filter bags) / per day;

2. High reputation: Listed company, +17 years experiences, Only focus on Air environment treatment;

3. Experienced product R & D team: We develop products tailored to our customers' needs based on years of industry experience and consideration of their specific working conditions, 108 national patents granted.

4. Leading equipment and technology: Germany AUTEFA full line (The first automatic needle changing system in the world), Bruckner high temperature setting line, Japan Tokuden laminating machine and Sweden ETON system are participated in the whole process;

5. Multiple inspect steps, dedicated to the commitment of superior quality: Covers +500㎡ analysis & test center, +50 sets analytical testing equipment: AFC-133 filter material Dynamic test platform (Germany), PSM-165 filter pore size tester (Germany), High performance liquid chromatography (U.S) etc.

6. Extensive experience on global market.

* Please note that the specific design, construction, and dimensions of filter bags may vary based on the equipment and filtration requirements. Customization options are available to meet specific application needs.