As an important support for my country's economic development, the impact of industrial development on the economy is indispensable. However, the ensuing environmental pollution problem is also very serious. The development of my country's industrial economy is the main driving force for the rapid development of the national economy, and the environmental pollution caused by it is also a major part of my country's environmental pollution. Its emission sources are mainly concentrated in several major areas such as coal-fired power stations, cement furnaces, and iron and steel metallurgy. The industrial flue gas emitted by these industries not only contains a large amount of harmful gases, and is accompanied by smoke and high temperature, but also with a large amount of particulate matter. And viruses and bacteria. These suspended matter will enter the body along with human breathing, causing physical damage.

For the filtration of industrial flue gas, bag dust removal technology is used, and its filtration efficiency can reach 99%. However, if it is to further improve the filtration efficiency, it encounters a bottleneck and fails to meet the stringent requirements for industrial flue gas emissions.

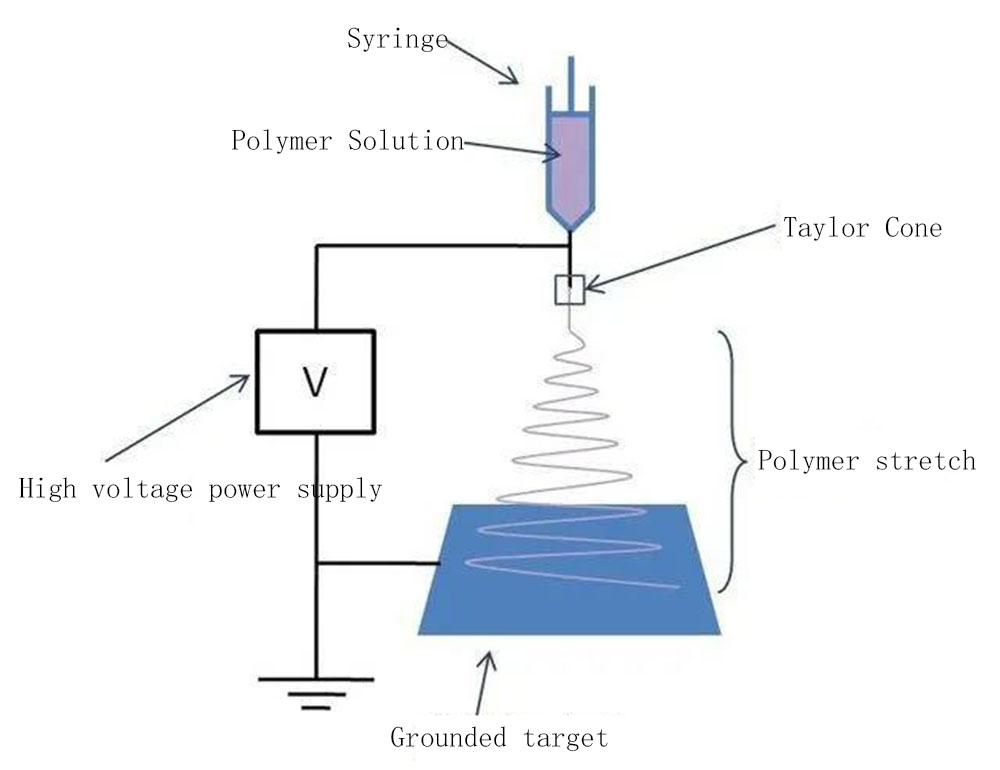

Based on this, many universities, enterprises and scientific research institutes currently use electrospinning technology to prepare nanofiber membranes, and use mature coating technology to attach the nanofiber membranes to the substrate filter material to filter conventional particles + The double-effect filter material that electrostatically adsorbs fine particles improves the filtration efficiency; the principle of the electrostatic spinning technology is as follows:

A high-voltage electrostatic field is formed between the spinneret of the liquid feeding device and the grounded receiving device. This high-voltage electric field will form an instantaneous electrostatic difference between the spinneret and the receiving device, causing the high polymer solution at the spinneret to melt or melt. The body is charged and overcomes its own viscoelastic force and surface tension to form charged hemispherical droplets at the spinneret. As the voltage increases, the hemispherical droplets do not stretch into a cone with a certain angle. This is the currently recognized Taylor cone. , Its angle is 49.5°. When the electrostatic field force is increased enough to overcome the surface tension of the charged droplets, the vertebral body is further stretched to form a continuous jet. In the electrospinning process, the droplets usually have a certain static voltage and are in an electric field. Therefore, when the diameter of the jet continues to decrease, spiraling, whiplashing, and splitting occur at the same time to finally form nano- or sub-micron fibers. With the volatilization of the solvent and the solidification of the solute or melt, it will eventually fall on the receiving device to form fibers.

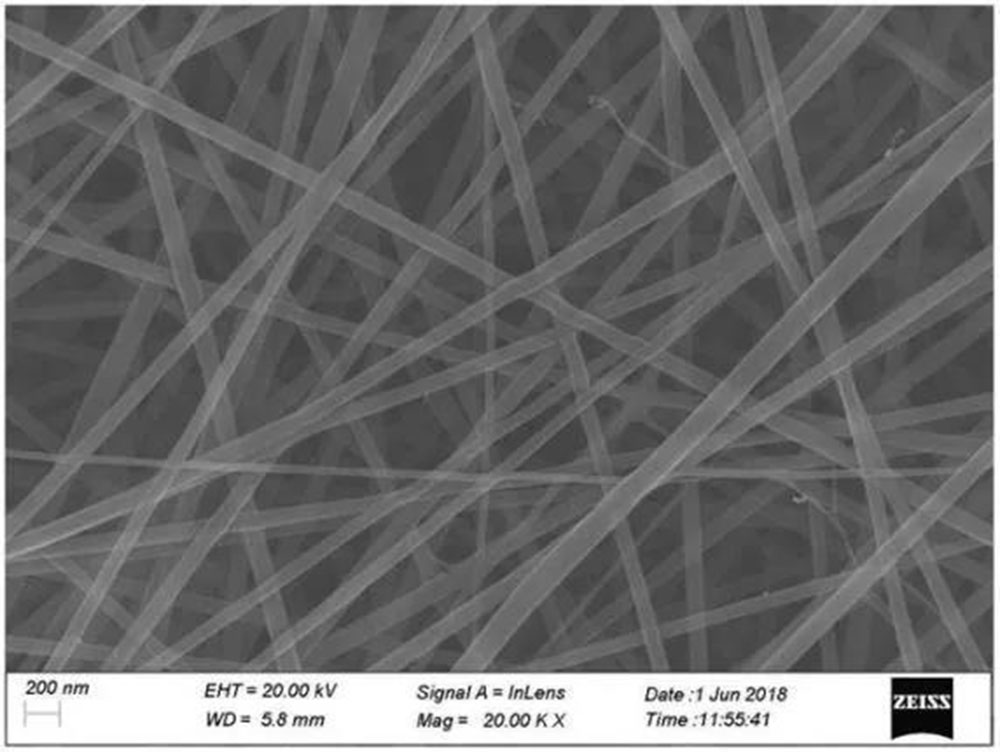

The prepared nanofiber has the advantages of low resistance, high filtration efficiency, small pore size, high porosity, etc., and has a good filtration effect. At the same time, the problems to be solved also exist: ① the composite fastness of the fiber membrane and the base needle felt; ② the mechanical properties of the fiber membrane; ③ the best spinning process of the fiber membrane and the stability in the production process.

Since the 1990s, with the development and wide application of nanomaterials, electrospinning technology has once again become a worldwide research and development hotspot, with a rapid development momentum. In the construction of basic theories of fiber forming, optimization of process parameters, development of new equipment, expansion of material sources, industrialization and application field development, extensive and in-depth research is still needed.