Yuanchen Technology Sharing-Microemulsion Dispersion Theory

Aug 20, 2021Oil and water are not mutually soluble, but can form an opaque emulsion dispersion system, which is the early "microemulsion". The microemulsion method has been widely used in materials science, pharmacy and engineering. Its essence refers to the use of two immiscible solvents to form a uniform emulsion under the action of surfactants. The microemulsion is thermodynamically stable, isotropic, transparent or translucent in appearance, and the diameter of the dispersed phase is about 1-100 nm.

In terms of functional filter materials, the microemulsion method can also be applied to the development of functional filter materials. The microemulsion method can prepare water-insoluble nanoparticles into a uniform and stable dispersion. The water-insoluble nanoparticles can be loaded on the surface of the fiber by the way of emulsion dipping, making the filter material waterproof, oil-proof, and strong. Integrated function with catalytic dust removal.

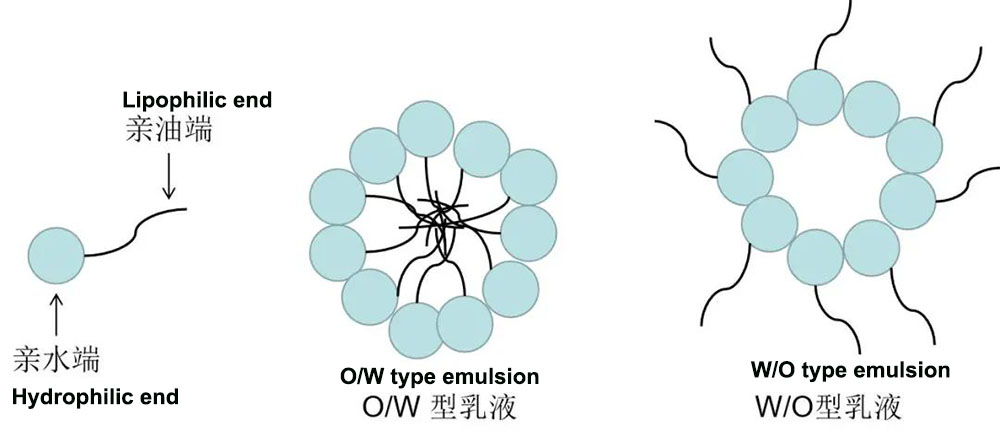

The key of the microemulsion method is to make each droplet of the aqueous solution containing the precursor be surrounded by a continuous oil phase (each droplet containing the precursor is surrounded by a continuous water phase), and the precursor is insoluble in the oil phase emulsion. That is to form a water-in-oil (W/O) emulsion or an oil-in-water (O/W) emulsion. The schematic diagram is shown in the following figure:

Microemulsions are usually composed of surfactants, co-surfactants, solvents and water (or aqueous solutions). In this system, two incompatible continuous media are divided into tiny spaces by surfactant amphiphilic molecules to form a micro-reactor whose size can be controlled in the nanometer range, and the reactants react in the system to form solid particles.

Because the microemulsion can accurately control the particle size and stability of the nanomaterials, it limits the nucleation, growth, coalescence, and agglomeration of the nanoparticle. The resulting nanoparticle is wrapped with a layer of surfactant and has a certain degree of Condensed matter structure. The solid phase is separated from the emulsion, so that the processes of nucleation, growth, coalescence, and agglomeration can be confined to a tiny spherical droplet, which can form spherical particles and avoid further agglomeration between the particles.

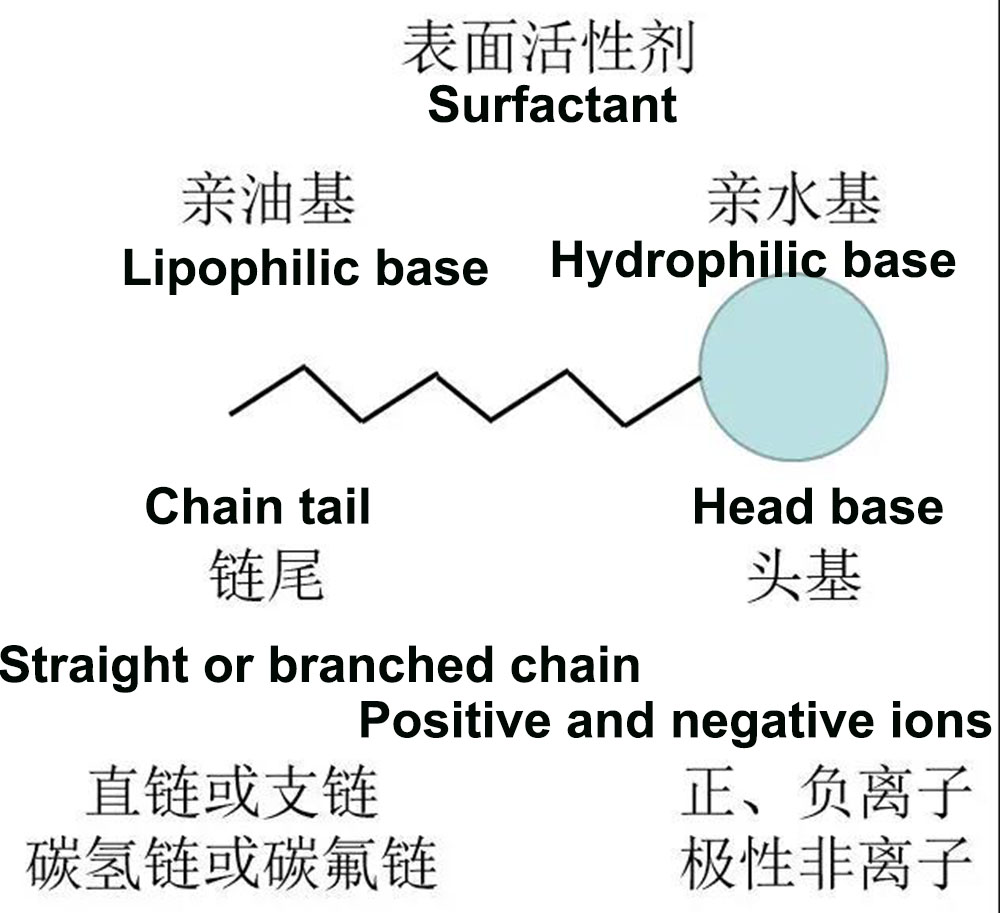

Commonly used surfactants are: double-chain ionic surfactants, such as dioctyl sodium sulfonate (AOT); anionic surfactants, such as sodium dodecyl sulfonate (SDS), dodecyl benzene Sodium sulfonate (DBS); cationic surfactants, such as cetyltrimethylammonium bromide (CTAB); non-ionic surfactants, such as TritonX series (polyoxyethylene ethers), etc. Commonly used solvents are non-polar solvents, such as alkanes or cycloalkanes. The mechanism of surfactant action is as follows:

Since the first public report of microemulsion for more than 70 years, the basic theory of microemulsion has been continuously developed and perfected day by day. Due to its good solubilization and stability, microemulsion technology has very broad application prospects in the fields of food, medicine, cosmetics, etc. In addition to the above, microemulsion can also be used in the coating industry, nanomaterials, environmental pollution, washing, Fuel and many other aspects. In order to comply with people's requirements for a healthy life, microemulsion technology is bound to cater to this trend and develop in the direction of safety, greenness and environmental protection.

With the development of microemulsion technology and rapidly changing market demand, it can be predicted that microemulsion will be combined with more industries to develop new technologies and products for people to use. The "PTFE composite emulsion membrane permeation" technology independently developed by Yuanchen Technology effectively improves the product's temperature resistance, acid and alkali corrosion resistance, and easy dust cleaning performance, and reduces operating resistance.