Yuanchen Technology reveals AR-21 gel silica-based super wear-resistant filter media

May 16, 2022

During the operation of bag filter, due to unreasonable design of dust removal system, improper installation, unreasonable setting of operating parameters, filter material and other reasons, it may cause the filter bag to break and fail, which in turn affects the service life of the filter bag, the operating status of the dust collector and the emission of particulate matter.

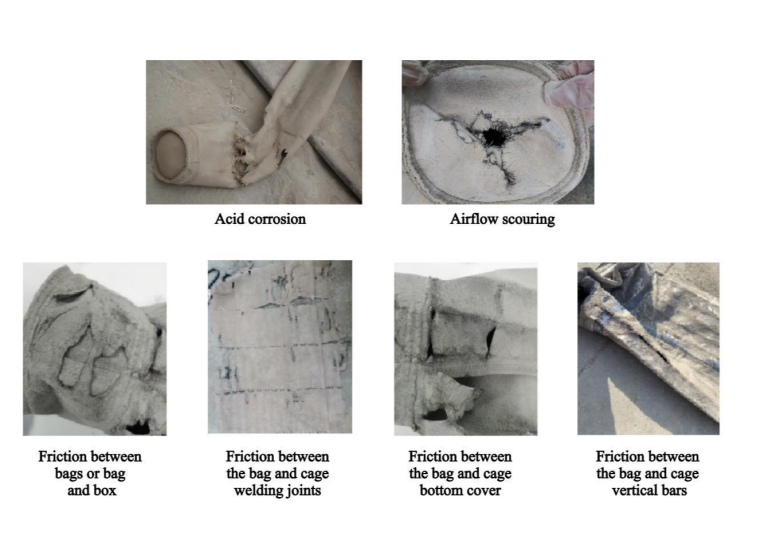

The reasons for the breakage of the filter bag during operation are chemical damage (acid and alkali corrosion, oxidation and hydrolysis, etc.), airflow scouring (inside and outside the bag) and mechanical friction, etc.

|

|

Figure1 Old bag breakage situations

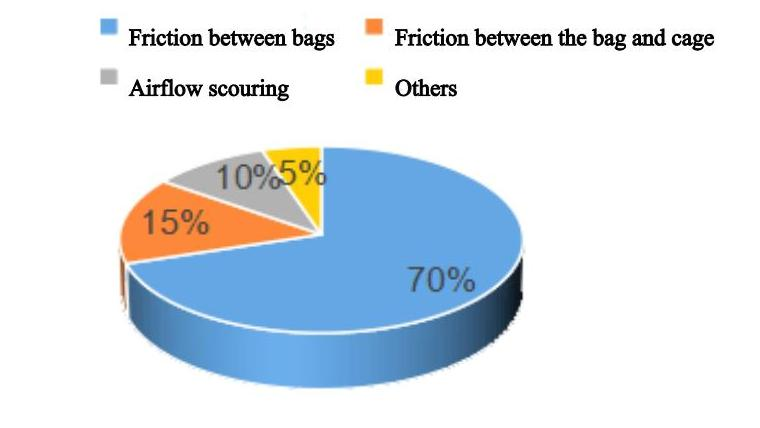

Figure 2 2021 annual testing center

old bag failure detection analysis results

According to the year 2021 Anhui Confair Testing Technology Co. Ltd. (CNAS, CMA ) old bag failure detection analysis results can be seen, as shown in Figure 2 above, excluding the dew paste bag phenomenon caused by the working conditions, where the number of broken filter bags is the most, and the main reason for the broken filter bag is the friction between the bag and the filter bag.

The highest percentage of filter bag breakage is caused by friction between bag and bag, accounting for 70% of the broken bags; so the effective method to improve the wear resistance of filter bags will effectively delay or avoid the failure of breakage caused by friction and extend the service life of filter bags.

In order to solve the pain points of customers and fundamentally improve the wear resistance of filter media, our technical advantages are.

1. Double-layer bag bottom strengthening technology.

2. AR-21 gel silica-based high wear-resistance filter media.

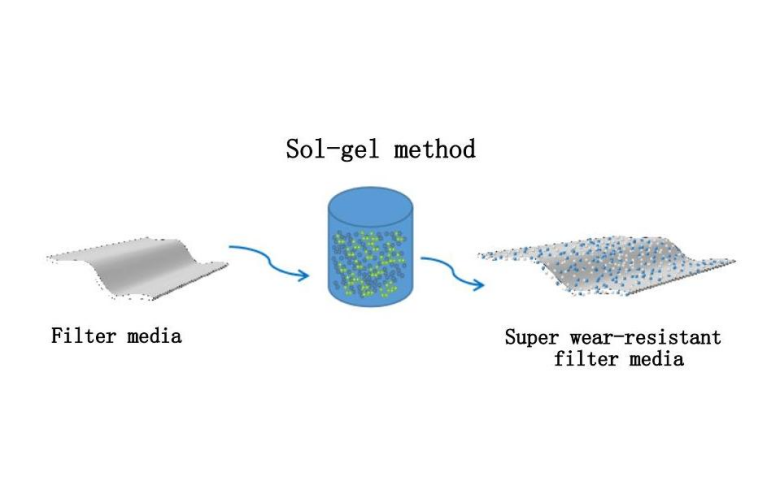

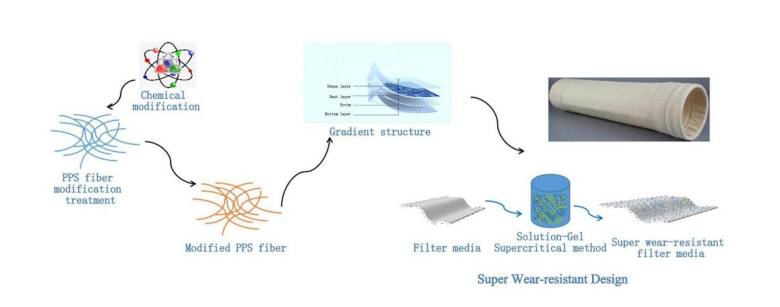

Yuanchen Technology uses modified fiber technology, premixed gradient technology and sol-gel-supercritical drying technology, as shown in Figure 3 below, to develop AR-21 gel silica-based highly wear-resistant filter media, which can adapt to the requirements of different working conditions and fundamentally improve the wear-resistant performance of the filter media.

Figure 3 Technical advantage - super wear-resistant technology

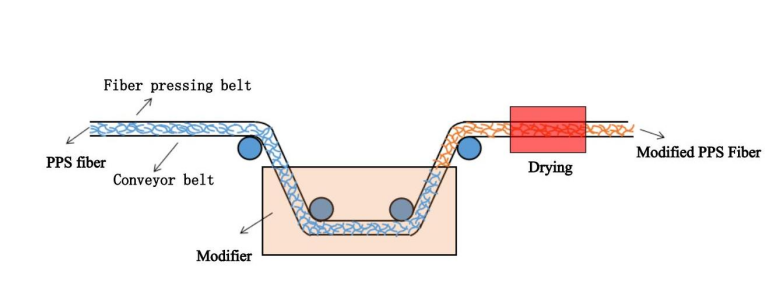

The technical innovations of AR-21 gel silica-based high abrasion resistant filter media are modified PPS fibers: by modifying the fibers to improve their tensile properties, which in turn gives the filter media excellent breaking strength and elongation at break.

Figure 4 Modified fiber treatment technology diagram

|

|

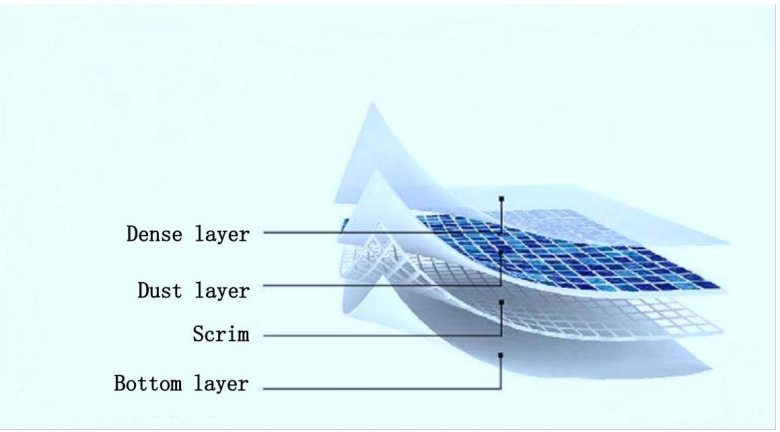

"Pre-mixed gradient" technology, designed pre-mixed-fiber/density graded combination of asymmetric gradient structure filter media, formed by ultra-fine fibers to form a dense layer and the bottom layer to form a density gradient structure, to achieve high-precision filtration, in the case of non-coated, can meet the dust particles ultra-clean emissions (< 5mg/Nm3), the filter bag operating resistance is lower than the coated filter media, to truly achieve "high efficiency and low resistance".

|

|

Figure 5 Pre-mixed gradient structure

Super wear-resistant technology, using the sol-gel method, the nanoscale silica-based particles gathered with each other to form a nanoporous network structure, and filled with gaseous dispersion medium in the network pores, using supercritical drying technology to make a gel silica-based materials, permeable membrane treatment technology to form super wear-resistant filter media.

Figure 6 Super wear-resistant technology diagram

AR-21 gel silica-based high abrasion resistance filter media has better tensile properties than ordinary gradient filter media and less fluctuation of breaking strength.

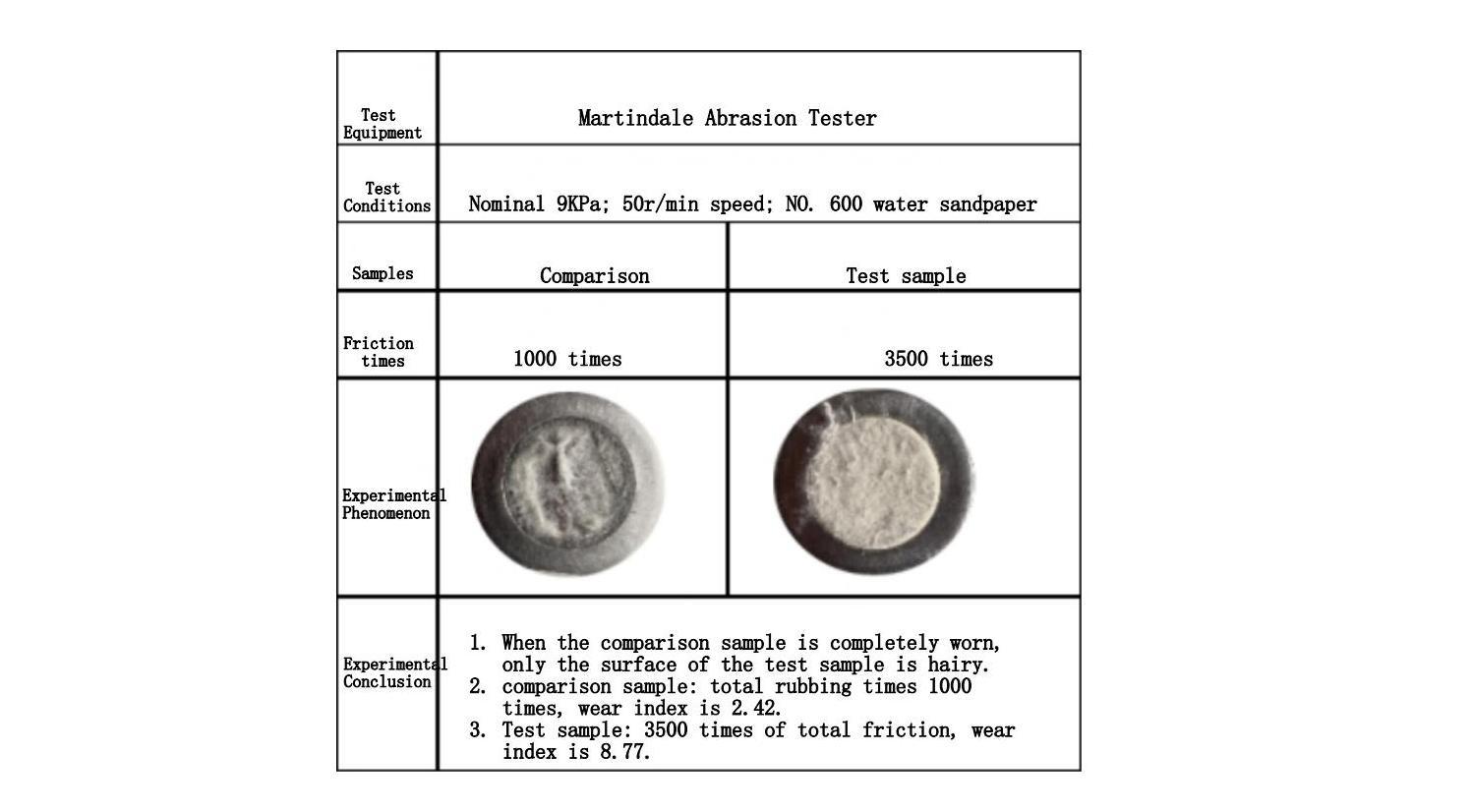

According to GBT 21196.2-2007 Determination of abrasion resistance of textiles by Martindale method Part 2: Determination of specimen breakage, the abrasion resistance of AR-21 gel silica-based high abrasion resistant filter media was measured.

The results of the abrasion resistance test are as follows.

The abrasion resistance index of AR-21 gel silica-based super abrasion resistant filter media increases exponentially, effectively resisting the breakage and failure of filter bags caused by friction.