Yuanchen Technology: Introduction to various carrier series SCR denitration catalysts (IV)

Oct 26, 2022Sabeti et al [37] used a special precipitation method to load an amorphous layer of MnOx on the surface of NaY zeolite microcrystals to obtain an eggshell-type MnOx/NaY denitrification catalyst, which achieved 80%-100% NO conversion at 200 °C under 5%-10% inlet gas moisture content. Qi et al [38] obtained bimetallic denitrification catalysts by first loading MnOx onto USY molecular sieves and then impregnating Ce or Fe, with NO conversions of 43% and 50% at 80 °C, respectively, and on 14%Ce-6%Mn/USY denitrification catalysts, with NO Liang et al [39] produced a V-OMS-2 denitrification catalyst by introducing vanadium ion (V5+) into MnOx octahedral molecular sieve (OMS-2) using a hydrothermal synthesis method. The highest catalytic activity was achieved at 2% V.

2.5 MnOx/other carrier denitrification catalysts

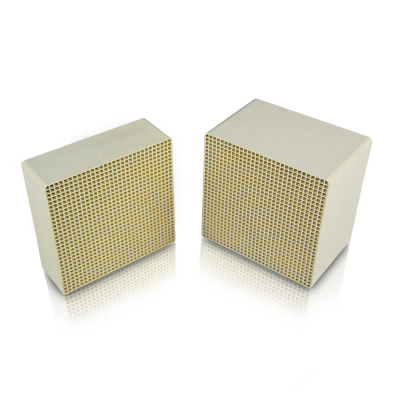

Zhou et al [40] prepared a multilayer composite denitrification catalyst alternately loaded with Mn-Ce-O/TiO2 and Cu-Ce-O/TiO2 using a sol-gel method with coccolithophore honeycomb ceramics as the carrier. The NO conversion efficiency on the denitrification catalyst reached 95% at 250 °C; the NO conversion efficiency was higher than 80% at 200~300 °C.

Huang et al [41] prepared Mn-Fe/MPS denitrification catalysts using MPS (mesoporous silicon oxide) as the carrier. The Mn-Fe/MPS denitrification catalysts showed the highest catalytic activity (NO conversion up to 99.1% at 160 °C) when n(Mn)/n(Fe) = 1. When the temperature was higher than 140 °C, H2O had no negative effect on the denitrification catalyst activity; the SCR catalytic activity gradually decreased in the presence of SO2 and H2O. Shen et al [42] prepared three titanium-based column clay (Ti-PILCs) carriers from TiC14, TiOSO4, and Ti(OC3H7)4, respectively, by the impregnation method to prepare Mn CeOx/Ti-PILCs denitrification catalysts were then prepared by impregnation. The Mn-CeOx/Ti-PILCs denitrification catalysts prepared from TiOSO4 had the highest catalytic activity for SCR reaction (up to 98% NO conversion at 220 °C) and showed good resistance to H2O and SO2; the Mn-CeOx/Ti-PILCs denitrification catalysts prepared from TiCl4 had the lowest activity.

It can be expected that future research work on SCR denitrification catalysts will mainly focus on widening their low temperature active temperature window, improving their H2O and SO2 resistance, and reducing the cost of denitrification catalysts.