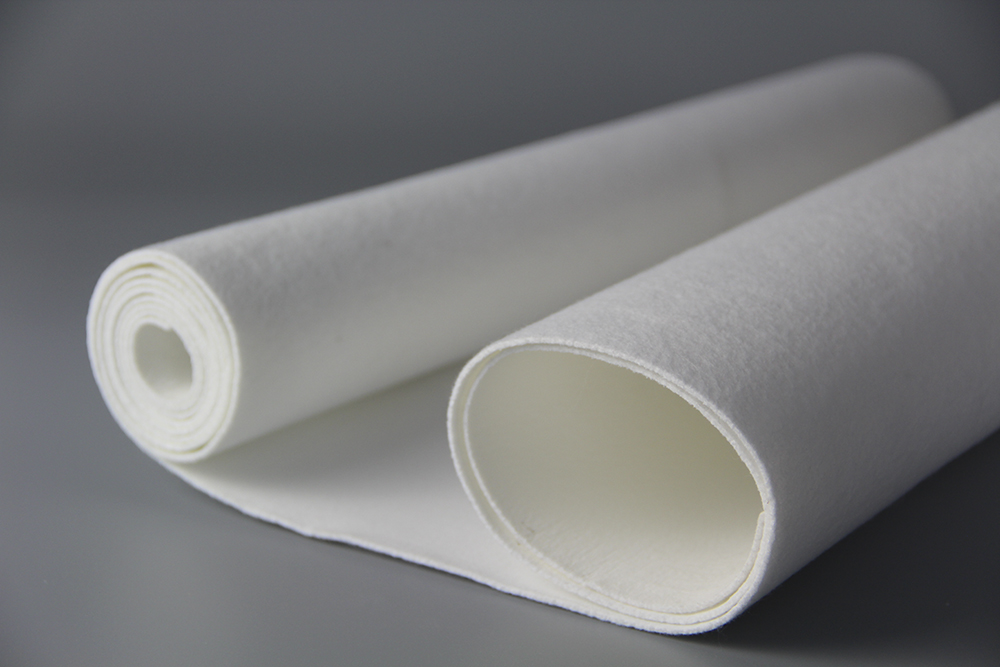

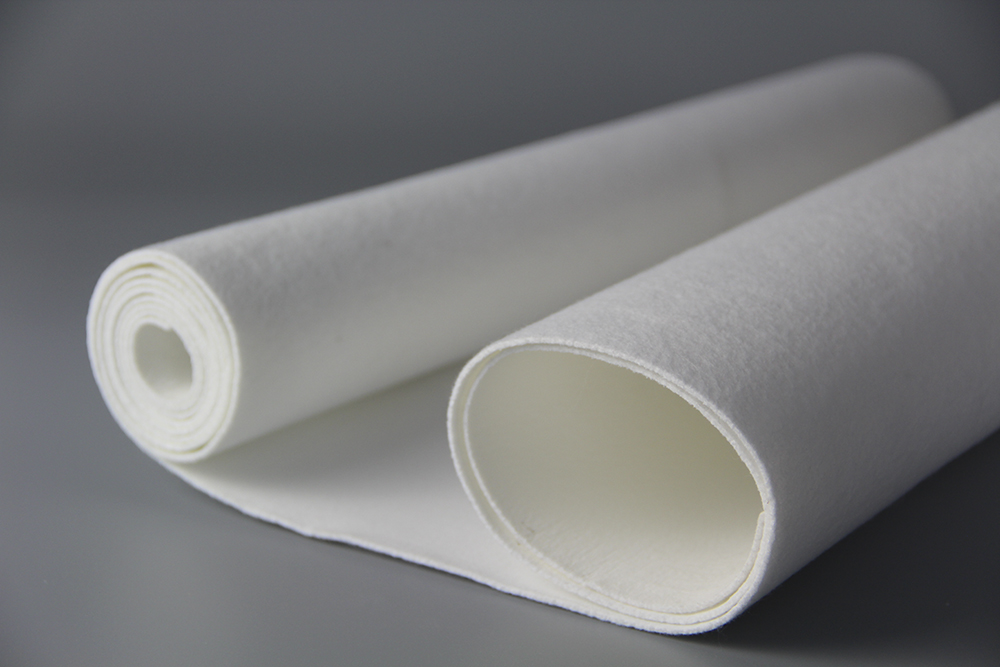

PTFE filter bag is in the needle felt filter material is attached to the surface of another layer of PTFE microporous sheet plastic film, so also known as PTFE laminated dust filter bag. This kind of plastic film is through the technical professional filter material laminating machine hot melt molding, it is proportional, and the porosity is very fine, the diameter is about 0.05μm ~ 3μm, equivalent to the general dust bag of the original soot layer, can shield the soot.

PTFE dust bag not only has the characteristics of the general PTFE filter material, and has a more detailed, higher ash removal efficiency, ash removal rate can reach 99.99%, can be said to be infinitely close to 100%, most can be said to have long maintained zero emissions. Its discharge concentration value can be completely reduced to within 10mg/Nm3.

PTFE laminated dust bag filtering fume and dust generally in two ways:

1. Surface filtration: the soot is blocked at the surface layer of the dust removal bag.

2. Deep filtration: according to the dust bag itself in the middle of the gap between the chemical fibers to carry out filtration, so that the soot is very easy to place inside the filter bag. The general filter bag is to carry out deep filtration, while the laminated filter material is surface filtration. We provide customized dust collector bags to meet the needs of our customers for different working conditions.