With the rapid increase in the consumption of various types of civil and industrial textiles, especially the demand for various textiles such as interior decoration, the fires caused by textiles have also been increasing. 1960s, Japan, Europe and the United States and other countries put forward the requirements for flame retardant finishing of textiles, and formulated various types of textile flame retardant standards.

According to the International Organization for Standardization, flame retardancy (or flame-resistance) refers to the properties possessed by a material that slows, terminates, or prevents flaming combustion. It can be an inherent property of the material or it can be given to the material by certain treatments. Textile flame retardant technology is based on the latter theory of applied research.

Modern combustion mechanism research shows that fabric combustion is a closed chain reaction process, and the purpose of positive combustion is to break the chain reaction, namely: in the exothermic phase, flame retardants are strong absorbers; in the thermal cracking phase, flame retardants act as catalysts to change the way of thermal degradation of fibers, so that they react in the direction of the reduction of combustible gases and increase of solids; in the flame zone, flame retardants are used to cut off the chain reaction by releasing free radicals of blocking agents, trapping agent to cut off the chain reaction, so that the active free radicals are blunted to achieve the purpose of flame retardant.

Currently, flame-retardant fabrics are generally made from fabrics that have been post-treated with flame retardants.

Dip-rollin method

The process flow is dip-rolling, pre-drying, baking, washing and post-treatment.

Dyeing method

It is generally used for hydrophobic synthetic fabrics and requires affinity between flame retardant and fiber.

Coating method

The coating method is a finishing method in which the flame retardant is mixed into the cross-linking agent or binder to fix it on the fabric.

Organic solvent method

The organic solvent method can directly use non-water-soluble flame retardants, which has the advantages of short flame retardant finishing process time and low energy consumption, but requires solvent recovery devices and attention to the toxicity of solvents.

Spraying method

Spraying method has two kinds of manual spraying and mechanical continuous spraying, for some surface fluffy with pattern, tufting or pile head pile fabric, generally can be used continuous spraying method.

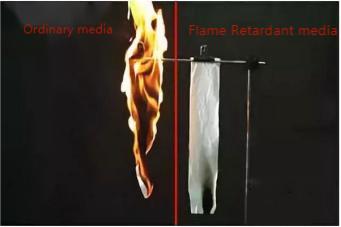

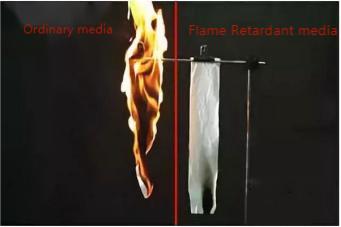

As a kind of textile, in the actual operation of the filter bag, when the flue gas temperature is too large, or the presence of sparks, it will lead to the burning and breaking of the filter bag, thus affecting the filtration efficiency, for the flame retardant filter bag, the R & D department of Yuanchen Technology has been working on the flame retardant filter bag research, combined with graft copolymerization, sol-gel and supercritical drying method and other technologies have developed the Star Oblivious ∙ fire retardant filter media, can adapt to different flame retardant It can meet the requirements of different flame retardant occasions and avoid the breakage of filter bags caused by sparks.

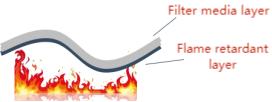

The Oblivious Fireproof series of filter media can directly resist flame burning by using layer-by-layer self-assembly and in-situ sol-gel technology to cover the surface of the filter media with an intumescent fireproof layer, thus forming a physical fireproof barrier to prevent external flames from eroding into the filter media. To further improve the fireproof performance, nanoparticles containing fluorine and silicon can be infiltrated into the fireproof layer. The ultimate oxygen index of Star Oblivious ∙ Fireproof series filter media is higher than 35, and the fireproof grade is A.

Oblivious fire-retardant series of filter media can effectively cope with all kinds of working conditions that generate sparks and sparks, and protect the safe and stable operation of dust collectors, and solve the painful problems for customers.