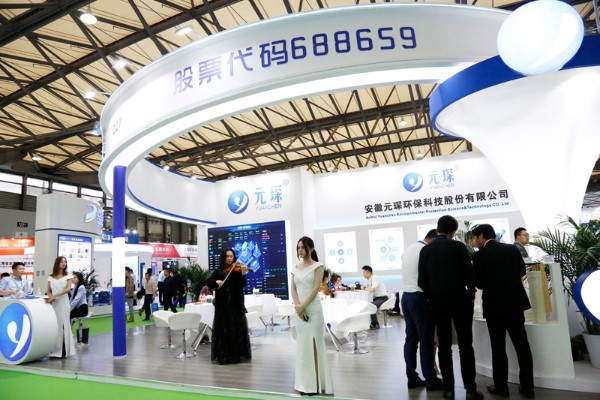

Yuanchen Showcases New Technologies And Products At The 24th China Environment Expo 2023 in Shanghai

Apr 23, 2023From April 19th to 21st, 2023, the 24th China International Environmental Expo was successfully launched. This year, the exhibition attracted participation from numerous environmental protection brands, among which Yuanchen Technology showcased its latest R&D achievements.

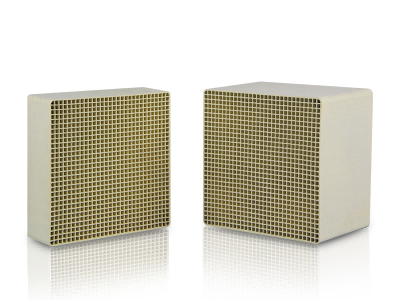

SCR Denitrification Catalyst

Energy-saving catalyst:

Energy-saving catalyst specifically designed for low-temperature denitrification in sintering machines, suitable for 140-200℃ operating conditions. This product optimizes the current 280℃ process, achieving significant gas savings and carbon reduction, with an impressive energy-saving efficiency of 41%! It has been successfully implemented by customers like Longteng Special Steel, Jianlong Steel, receiving high acclaim.

DeCO catalyst:

It can realize the pollution control of CO, and at the same time realize the oxidation heating, and realize the role of supplementary energy. Specially used in sintering machine, hot blast furnace, heating furnace, cement, lime kiln, hazardous waste incineration and other fields.It can effectively control CO pollution, while providing oxidation heating and serving as a supplementary energy source. It is specifically designed for applications in sintering machines, hot blast furnaces, heating furnaces, cement and lime kilns, hazardous waste incineration, and other related fields.

Wide-temperature catalyst:

Wide temperature range catalysts are utilized in the temperature range of 225-420℃. They can operate efficiently under low loads for extended periods, ensuring compliance with emission standards and achieving ultra-clean denitrification throughout the entire process.

Dioxin reduction catalyst:

It simultaneously achieves dioxin removal and denitrification, integrating SCO and SCR processes. Operating within a temperature range of 160-220℃, it achieves a remarkable efficiency of over 90%. Primarily applied in waste incineration, hazardous waste incineration, sintering machines, biomass power generation, coking, and other industries.

Cement catalyst:

In response to catalyst wear in flue gas treatment in the cement industry, the company has developed durable catalysts lasting over 24,000 hours, with a wear rate of 0.03%. This opens up possibilities for catalyst regeneration in cement production.

For more DeNOx catalysts details, please visit Yuanchen's DeNOx Catalyst page.

If you would like to receive the latest product quotation, please provide us with your equipment model and fill in some necessary operating parameters. We will provide you with a quotation based on your detailed information.

↓ ↓ ↓ ↓ ↓

Dust Collector Filter Fabric

High efficiency & Low resistance carbon reduction filter media:

In response to the pain point of high energy consumption and high operating cost from the user side, our R&D team has developed PTFE high efficiency low resistance membrane through membrane microstructure design, regulation and optimization, with high porosity, high permeability, small pore size and concentrated distribution, thus realizing the effect of high efficiency low resistance, pollution reduction and carbon reduction, and reducing energy consumption by Addressing the challenge of high energy consumption and operating costs, our R&D team has developed PTFE membranes with optimized microstructure design. Featuring high porosity, permeability, and concentrated distribution of small pores, it achieves high efficiency, low resistance, pollution reduction, and carbon reduction, resulting in 20%-30% energy savings.

Co-NOx dust removal and denitrification catalytic filter media:

Combining dust removal and denitrification catalytic functions in one, with a wide range of activity temperature (By combining dust removal and denitrification catalytic functions, our solution offers a wide operating temperature range (140-240°C) and achieves up to 99% denitrification activity (at 220°C). This enables the transformation of filter material into a functional coupling type, enabling synergistic treatment of multiple pollutants., realizing the transformation of filter material to functional coupling type and multi-pollutant synergistic treatment.

AR-21 gel silica-based super wear-resistant filter media:

To address the issue of abrasion caused by high filtration wind speed and dust concentration, we have developed a highly abrasion-resistant filter media using the sol-gel method. This innovative solution provides more than twice the abrasion resistance and MIT performance, effectively extending the service life of the filter media.

Flame retardant filter media:

In view of the fact that the dust in the dust collector is prone to secondary combustion and bag burning, we have developed Flame-retardant filter media by graft copolymerization and supercritical drying method, which achieves the flame-retardant grade A and isolates the damage to the filter media from external flames.Considering the risk of secondary combustion and bag burning in dust collectors, we have developed flame-retardant filter media using graft copolymerization and supercritical drying methods. This innovative solution achieves a flame-retardant rating of Grade A, effectively isolating the filter media from external flames and preventing damage.

For more dust collector filter fabric details, please visit Yuanchen's Filter Cloth page.

If you would like to receive the latest product quotation, please provide us with your equipment model and fill in some necessary operating parameters. We will provide you with a quotation based on your detailed information.

↓ ↓ ↓ ↓ ↓

Yuanchen shows On The 24th China Environment Expo 2023

Founded in 2005, Yuanchen Technology focuses on technology development and application in the field of environmental protection, pioneering and innovating in industrial flue gas filtration, denitrification, circular economy, intelligent environmental protection, etc. It is committed to the frontier of industry technology and promotes the integration of new business models in the environmental protection industry, and is an enterprise with the qualification of R&D, design and production of high-efficiency filtering materials and SCR denitrification catalysts as well as recycling and reclamation of used catalysts, with CNAS and CMA testing qualification.