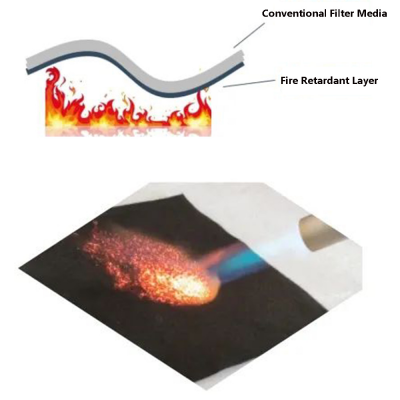

In places with explosive dust (such as coal mining fields, metal powder processing, flour mills, etc.), under certain conditions, sparks, open flames, and even deflagration or explosions may occur. Therefore, the flame retardant or fire resistance of the filter material is very important, which can effectively prevent the danger.

Yuanchen Technology combines the strengths of "physics and chemistry" and combines graft copolymerization, sol-gel and supercritical drying methods to develop Xingyuan Fire-retardant filter material, which can meet the requirements of different flame-retardant occasions. Xingyuan·Fire-retardant filter material is divided into two series - fire-retardant series and fire-resistant series.

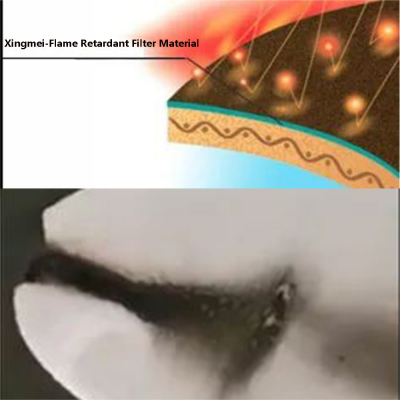

Xingyuan∙ Flame Retardant series filter material can directly resist the collision of sparks. After leaving the flame, it can self-extinguish immediately, and will not continue to burn or smolder. Xingyuan∙flame retardant series filter media combines grafting, flame retardant modification and membrane permeation treatment. The flame retardant performance of filter media is improved by grafting technology (such as filter media and styrene sulfonate graft copolymerization), and the performance of flame retardants is improved by adding siloxane additives and nanoparticles to conventional flame retardants. The flame retardant filter material was prepared by membrane permeation treatment. The limiting oxygen index of Xingyuan·flame retardant series filter material is about 30, and the flame retardant grade is B1.

Yuanchen Technology's flame-retardant-fire-retardant technology can be applied to different types of fibers. Xingyuan·Fire-retardant and flame-retardant series filter materials can effectively deal with various working conditions that generate sparks and sparks, escort the safe and stable operation of dust collectors, and create new products for customers. more value.