VOCs advanced treatment technology and process-waste gas efficient treatment equipment

Sep 16, 2021Main technology and equipment①

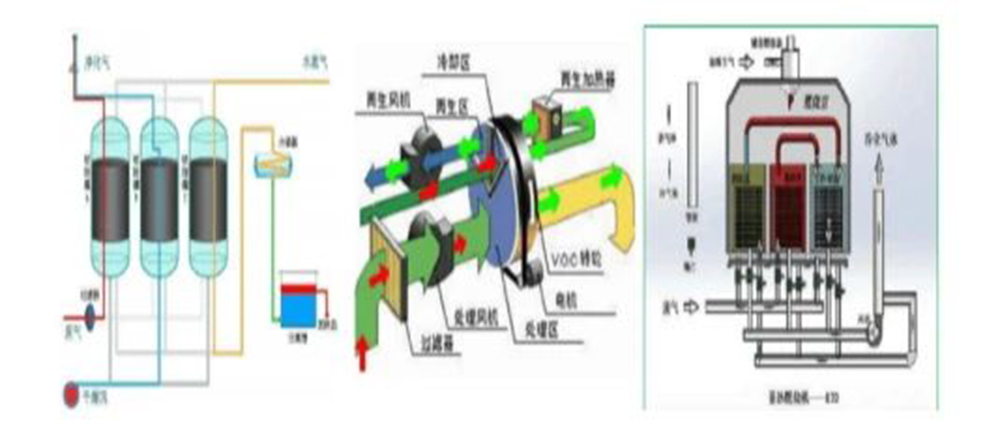

Adsorption technology: solvent adsorption recovery (activated carbon/activated carbon fiber adsorption device); adsorption concentration device (zeolite runner/honeycomb activated carbon)

Thermal incineration technology: RTO/TO/TNV

Catalytic combustion technology: RCO/CO

The above-mentioned processes and equipment have the widest range of application, the largest market share, and the largest contribution to the reduction of VOCs. They are currently the mainstream technology for VOCs governance.

Main technology and equipment②

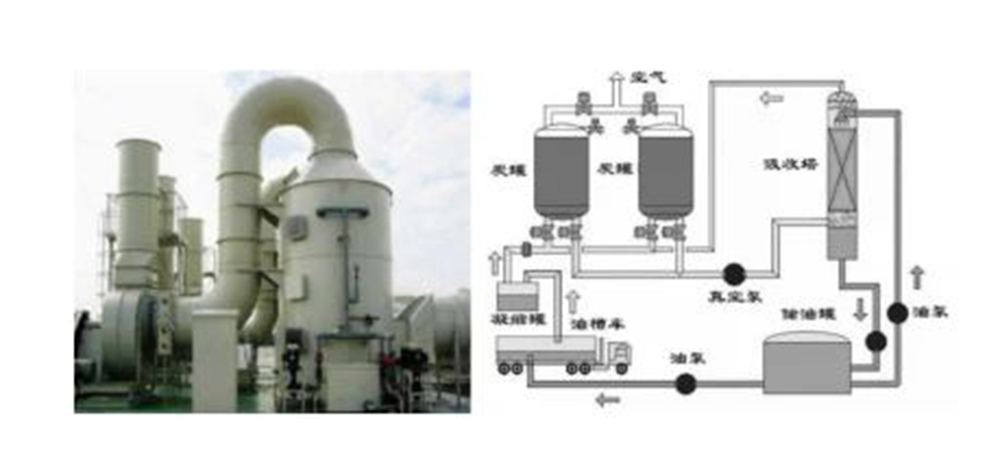

Adsorption technology: pre-treatment (spray tower), post-treatment (activated carbon adsorption + oil gas recovery)

Condensation technology: suitable for the purification of high boiling point and high concentration gas, usually other technologies are needed to achieve compliance discharge (such as condensation + adsorption technology)

Absorption and condensation technology has a narrow application range, and is usually used in the pre-treatment and post-treatment processes of VOCs. It plays an "auxiliary" role in the combined treatment process, but it is essential for certain industries.

Main technology and equipment ③

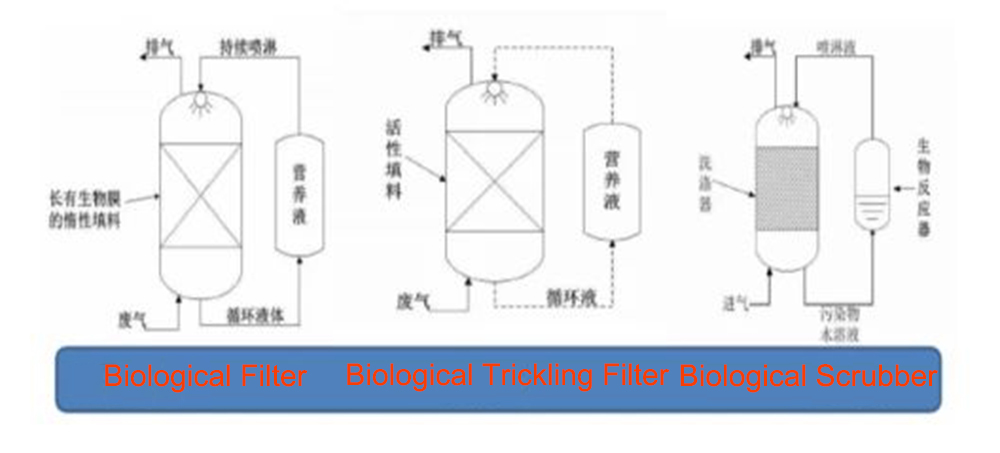

Biological purification technology is mainly used for exhaust gas deodorization. It is widely used in sewage treatment, garbage treatment, chemical, pharmaceutical, pesticide, food processing and production industries. In recent years, progress has been made in the cultivation of biological strains, biological fillers and biological purification processes, and the scope of application has continued to expand. Biological purification technology has become one of the main technologies for the treatment of organic waste gas.

Main technology and equipment④

Low-temperature plasma/photocatalysis/photooxidation technology is a kind of destruction technology. Due to its low purification efficiency (20-50%), it is easy to produce secondary pollutants, so it is usually combined with absorption technology to improve efficiency. It is usually used for the purification of gas odor after reaching the emission standard. This type of technology has received a large number of applications between 2013 and 2018, which has caused great confusion to the market. At present, the "sudden brake" method has been adopted to restrict its use. It is legal to restrict this type of technology to the field of low-concentration odor control in the "Comprehensive Treatment Plan for Volatile Organic Pollutants in Key Industries" in 2019.