Though Woven, the Filter Cloth has Much to Accomplish Before Becoming Qualified Filter Bags

Apr 28, 2023In the process of dust removal, as dust-laden gas particles flow through the dust collector, the dust particles are captured on the outer surface of the bag, while the clean gas passes through the filter media into the bag. The dust cage inside the dust collector bag provides support, prevents bag collapse, and aids in the removal and redistribution of the dust cake. Post-treating the dust bag is crucial for certain special working conditions. The post-treatment procedures are categorized as follows:

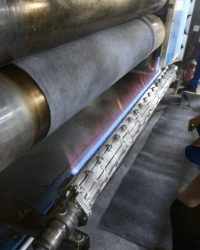

This treatment mainly involves exposing the fabric surface above the conveyor to fire, burning off lint, and then using high-temperature rollers to iron the fabric surface, making it smooth and easier to remove ash. This not only enhances the filter media's ash cleaning performance but also enables the collection of fine dust.

Singeing and calendering treatment

Explore our product page to discover the material supply range of dust filter cloth:

↓ ↓ ↓ ↓ ↓

PTFE / PPS / Nomex / Polyester / Acrylic / Fiberglass / FMS / Polyamide

Some types of dust can easily ignite when exposed to sparks in certain concentrations. Therefore, flammable or explosive dust requires anti-static treatment using needle felt filter media. Anti-static filter media incorporates conductive fibers or conductive yarn woven into the filter media to impart overall conductivity. This enables static electricity to flow through the filter media, guiding it to the dust collector box and grounding, thereby preventing explosions caused by static sparks.

Antistatic treatment

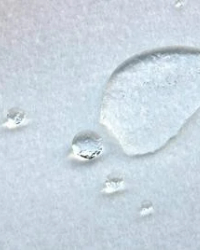

The needle-punched felt filter media is treated with fluorocarbon resin and PTFE, making the surface of the filter bag hydrophobic. This creates a lotus leaf-like effect, causing water droplets to roll off the fabric surface, enhancing dust trapping and preventing issues like bag sticking and corrosion caused by dew in situations with significant temperature differences.

Water and Oil - proof treatment

Interested in knowing which international customers Yuanchen Technology has? Browse our project case page to learn about the distribution of some of our customers.

↓ ↓ ↓ ↓ ↓

PTFE (Polytetrafluoroethylene) lamination treatment is a process in which a layer of PTFE is applied to the surface of a material or substrate. PTFE is a synthetic fluoropolymer known for its nonstick properties, high temperature resistance, and chemical inertness. The lamination treatment involves bonding or coating the material with a thin layer of PTFE, creating a smooth and nonporous surface. This treatment is commonly used in various industries, including filtration, to enhance the performance of filter media. PTFE lamination improves the filtration accuracy, prevents dust adhesion, facilitates easy cleaning, and reduces the risk of dust penetration into the filter media.

PTFE lamination treatment

In addition to post-processing, dust bags should undergo heat-setting treatment. Heat setting eliminates residual stress during the bag manufacturing process, ensuring stable bag size and a flat surface. If the bag size is unstable, it can easily deform during use, increasing friction with the support structure and making it difficult to remove the support, leading to severe dust accumulation.

If you would like to receive the latest product quotation, please provide us with your equipment model and fill in some necessary operating parameters. We will provide you with a quotation based on your detailed information.

↓ ↓ ↓ ↓ ↓

Contact Us