With the development of textile technology, it has become a development direction to improve the filtration performance of

filter bag materials by improving the processing technology of filter materials. The processing technology of the current filter material manufacturer-Anhui Yuanchen Environmental Protection Technology Co., Ltd. has the following types:

(1)Adopt membrane filtration technology. Membrane filtration technology refers to covering a layer of biaxially stretched PTFE microporous membrane on the surface of the traditional filter material to perform surface filtration with higher efficiency. Because the filter membrane has dense micropores, and the pore size reaches the micron or even nanometer level, the filtering effect of the filter bag is improved.

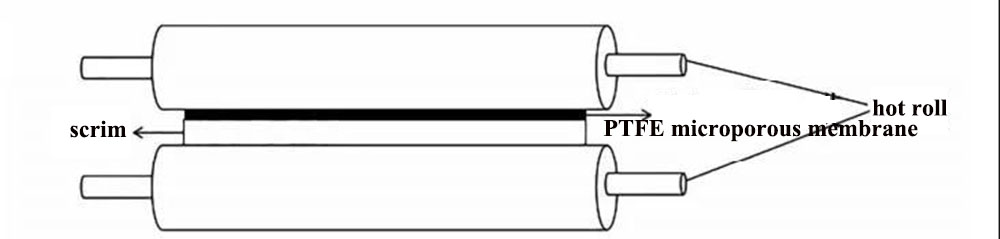

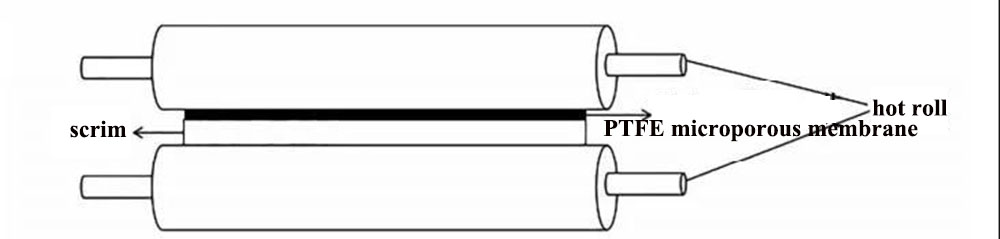

Through the use of film technology, more stringent emission standards can be met. For example, the PTFE film is coated with micro-pores on the surface through a special process. When the flue gas is filtered, the dust is filtered on the surface of the filter bag. Change the traditional phenomenon of deep filtration of dust particles in the filter bag, and reduce the content of soot particles in the filter bag layer during filtration. The laminating process generally includes high temperature hot pressing method and adhesive method. The adhesive method refers to coating a layer of adhesive on the surface of the ordinary filter material, and the filter material is combined with the film through the bonding effect when heated. The adhesive method has a simple process flow. But it is not suitable for high temperature use. Therefore, the effect of hot-pressing the filter material and the film by the high-temperature hot-pressing method is better than the adhesive method.

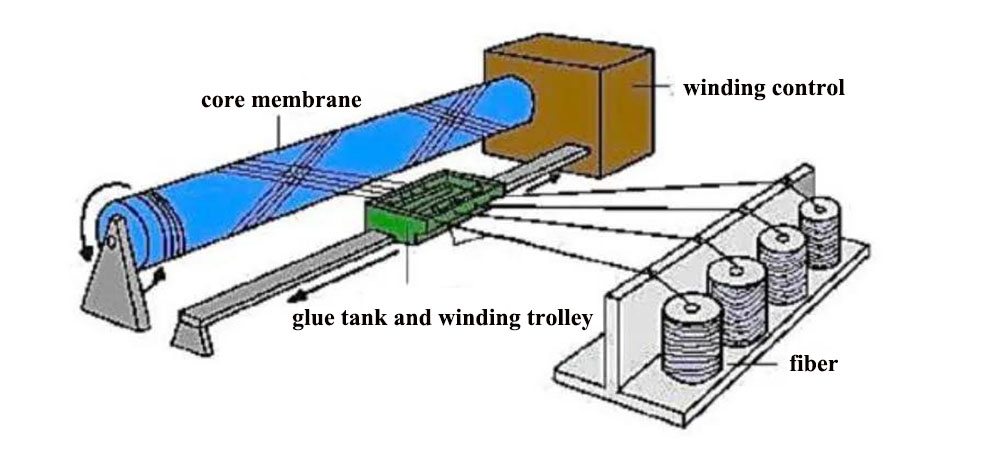

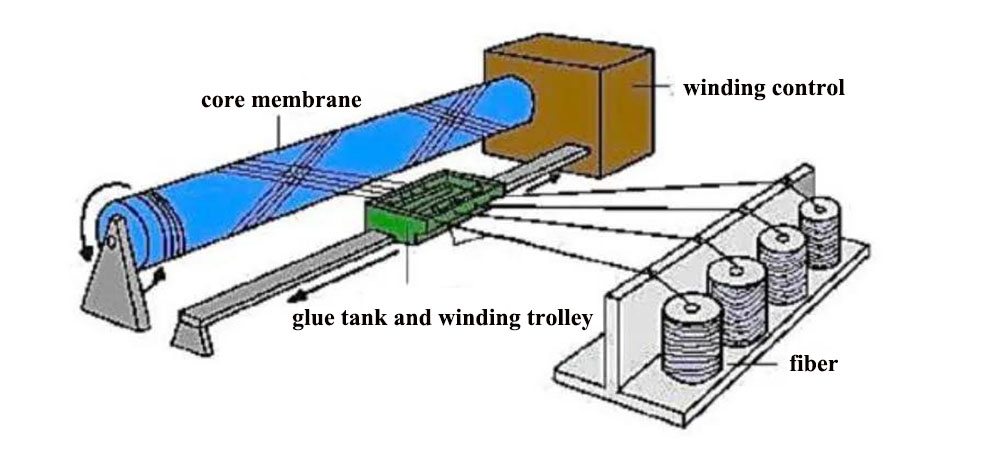

(2)Composite material technology. Due to the harsh and complicated soot filtering environment, a single fiber is often unable to meet diverse requirements. Combine two or more kinds of fibers to make use of their advantages and make up for the shortcomings between them. According to the special physical and chemical properties of different fibers (organic/inorganic fibers), they can be combined with each other to meet the requirements of filter material selection under different working conditions.

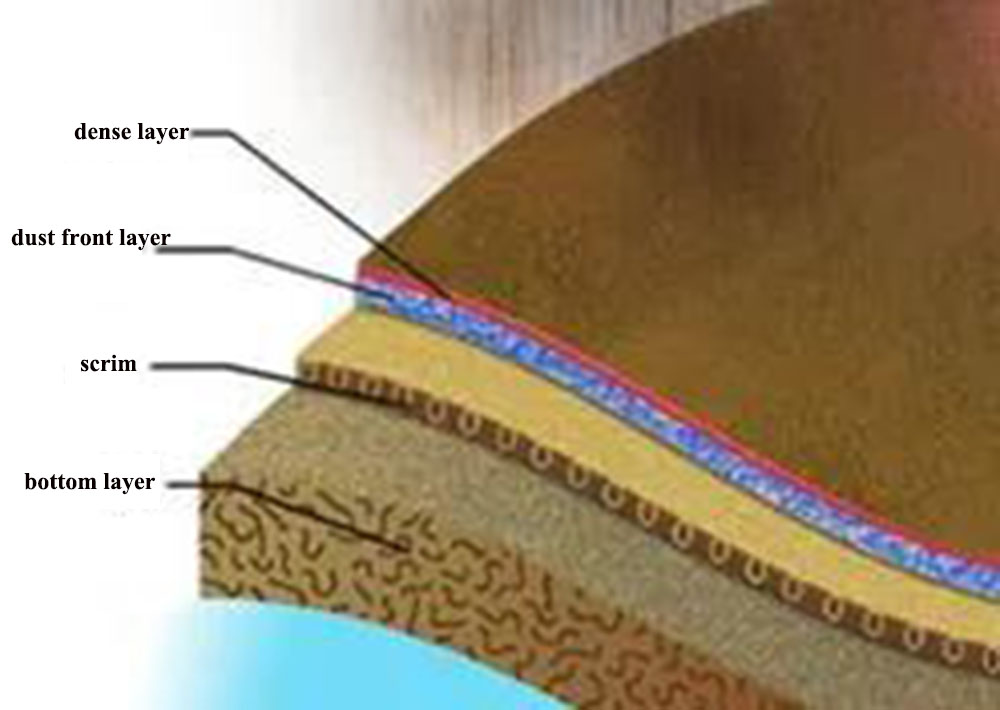

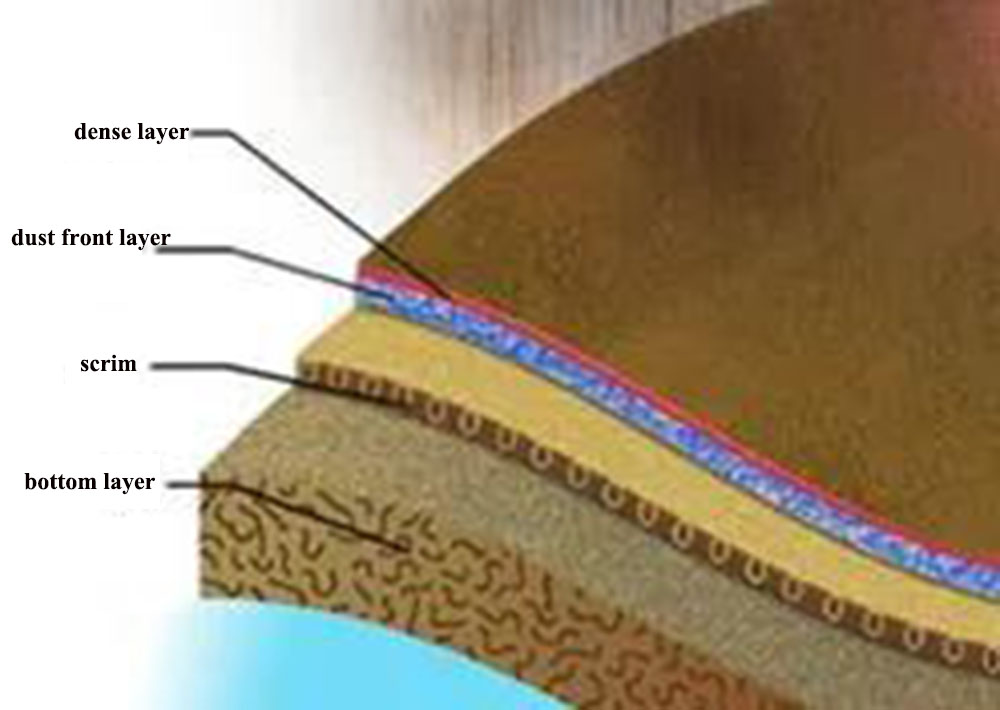

(3)Gradient processing technology. In the processing process, different filter layers are used, and different fineness fibers and different needle punching densities are used between different layers. The ultra-fine surface layer gradient structure filter material is a new type of filter material developed for the increasingly stringent smoke emission standards. It is mainly divided into four parts, from top to bottom: ultra-fine fiber layer, fine fiber layer , Base cloth and coarse fiber layer. The traditional filter material adopts a sandwich layer symmetric structure, that is, the fiber materials of the upper and lower layers of the base cloth are exactly the same, and the filtering method is deep filtration; the filter material adopts a graded structure of a combination of denier/density. The specific structure is shown in the figure below.

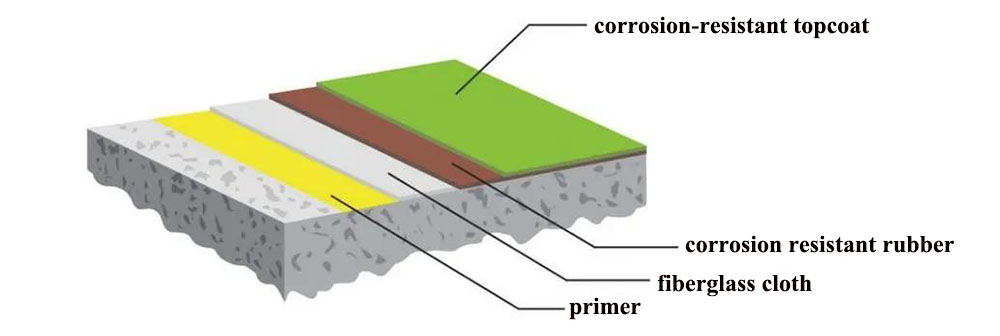

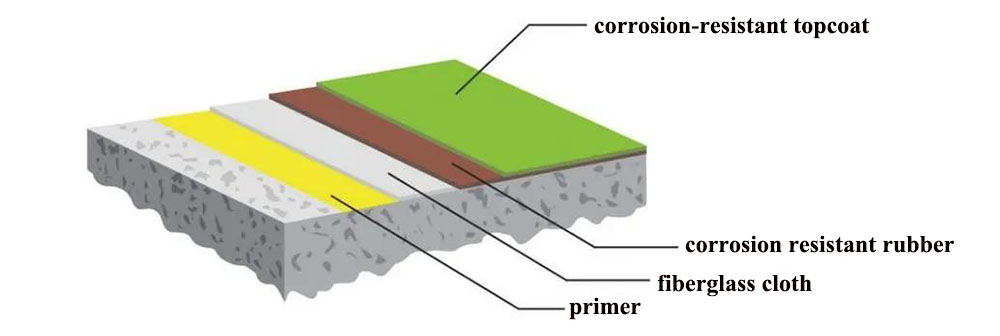

(4)Pre-coating technology. Coating refers to the uniform application of polymer compounds on the surface of the material, which is heated to form a film to give or enhance some special functions of textiles, such as heat resistance, acid and alkali resistance, etc., so as to meet different production and use needs. Because the paint will be selected to have good air permeability, not easy to agglomerate, flame retardant, antistatic and other properties. The internal dust holding capacity can be controlled, and the phenomenon of poor filtering effect of the filter bag during the formation of the dust layer can be avoided.

Yuanchen Technology

Yuanchen Technology (stock code: 688659) was founded in 2005 with a registered capital of 160 million yuan. It focuses on technology research and application in the field of environmental protection, and pioneers and innovates in the fields of industrial flue gas dust removal, denitrification, circular economy, smart environmental protection, and testing. It is an enterprise that has both high-efficiency dust removal filter materials and SCR denitrification catalyst research and development, design, production, and waste catalyst recovery and regeneration qualifications.