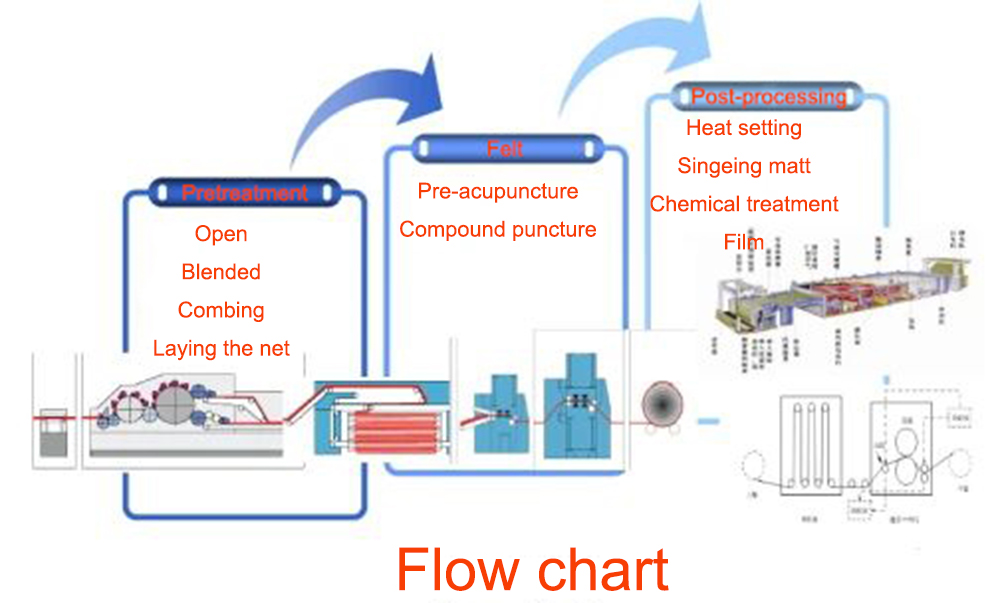

The main technological process of the needle punched non-woven filter material for the bag filter is: opening-mixing-fine opening-carding-netting-needle punching-finishing-slitting bag making.

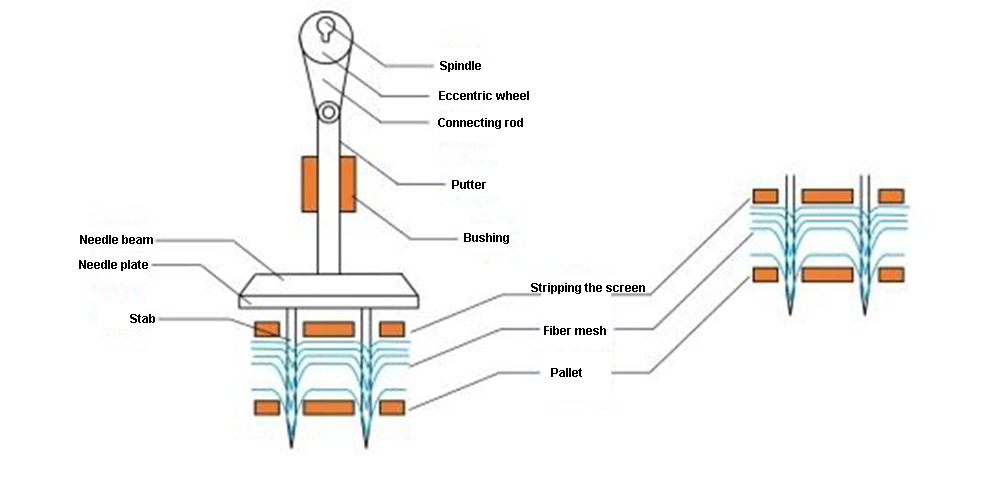

The needle-punching non-woven process uses barbed thorns on the edges to repeatedly puncture the web. When the barb passes through the web, it pierces the surface of the web and part of the inner web into the interior of the web. Due to the friction and cohesion between the webs, the original fluffy web is compressed. When the felting needle exits the fiber web, the pierced fiber bundles break away from the barbs and stay in the fiber web. After multiple needle punches, the fibers in the fibers are entangled with each other, thereby forming a non-woven material with a certain strength and thickness. The most important thing in the acupuncture process is to reasonably distribute the acupuncture density and control the acupuncture depth.

On the basis of the traditional fuel tank structure, the elliptical trajectory needle punching machine is equipped with a novel multi-link mechanism auxiliary transmission, which combines the vertical movement of the puncture needle and the horizontal movement of the puncture needle into an elliptical movement trajectory, which can follow the traveling direction of the needle felt Joint movement, while maintaining a stable up and down movement, while achieving mechanical reinforcement, does not damage the mesh structure, and maximizes the uniform mechanical strength of the cloth surface.