Mixing of dust removal filter material technology

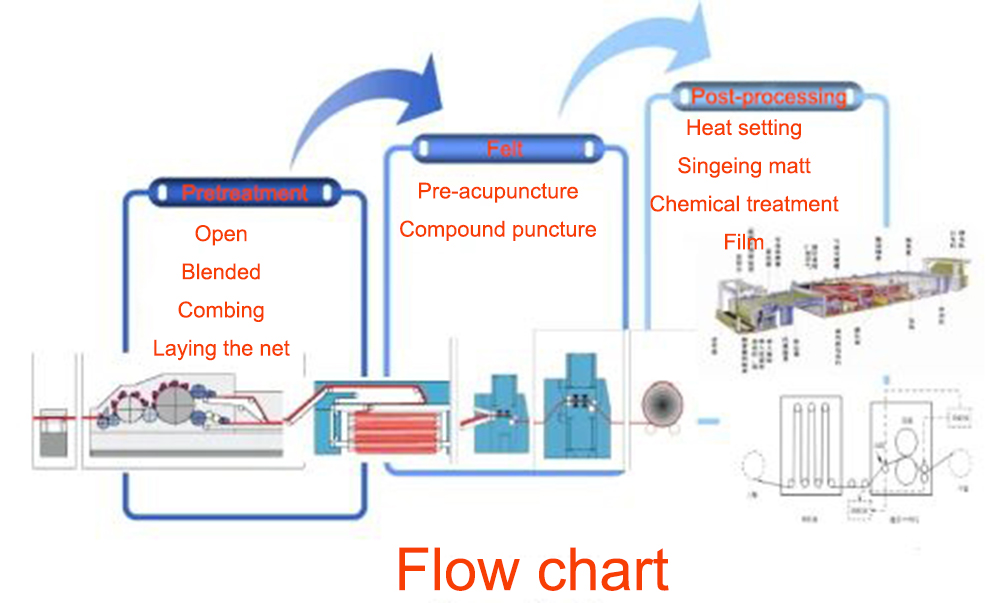

Sep 22, 2021The main technological process of the needle punched non-woven filter material for bag filter is: opening-mixing-fine opening-carding-netting-needle punching-finishing-slitting bag making.

The fiber opened by the bale opening machine is much looser than the fiber bale, but it still cannot meet the requirements of uniform mixing and opening degree. It is necessary to further use the blending box to mix and open the raw materials. The purpose of the blender is to fully open and mix the raw materials.

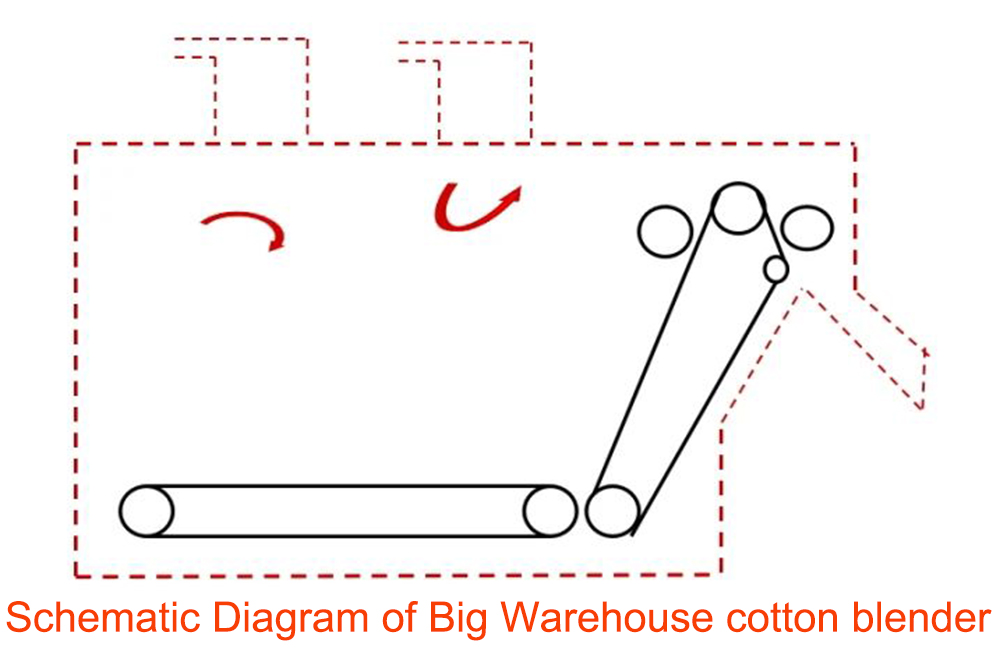

According to the configuration and form of the equipment, the mixing box type is generally divided into a large warehouse cotton mixing machine, a multi-bin cotton mixing machine and a semi-automatic cotton mixing machine.

The big warehouse cotton blending machine takes the fiber that has been unpacked by the bale opener, and sends the fiber through the pipe to the cotton outlet of the cyclone separator at the top of the cotton storage bin under the action of the fan. °Rotate and reciprocate along the longitudinal center of the cotton storage bin at the same time, and the ejected fibers are evenly thrown and accumulated layer by layer.

Yuanchen Technology always pays attention to product quality and quality first, and invests in the introduction of advanced Autefa acupuncture production line from Germany for the production of acupuncture filter materials.

The production line is equipped with two large warehouse cotton blenders to realize the full mixing of the upper and lower fiber materials of the filter material, and make full preparations for the quality of the final product.