Frontier of Science and Technology Innovation Analysis of the Development of Domestic Intelligent Manufacturing Industry

Aug 19, 2021According to the definition of the "Intelligent Manufacturing Development Plan (2016-2020)" issued by the Ministry of Industry and Information Technology and the Ministry of Finance, Intelligent Manufacturing (IM) is based on the deep integration of a new generation of information and communication technology and advanced manufacturing technology, including basic commonalities , Key technologies, and industry applications.

In recent years, the manufacturing industry has regained the focus of developed countries, such as the German Industry 4.0 strategy and the American advanced manufacturing strategy. The remanufacturing of developed countries has promoted the accelerated arrival of the era of intelligent manufacturing.

"Made in China 2025", as the action plan of the manufacturing power strategy, clearly takes intelligent manufacturing as the main direction, and proposes: speed up the intelligent transformation of production equipment in machinery, aviation, shipbuilding, automobile, light industry, textile, food, electronics and other industries to improve precision Manufacturing and agile manufacturing capabilities; coordinate the layout and promote the R&D and industrialization of products such as smart transportation tools, smart construction machinery, service robots, smart home appliances, smart lighting appliances, and wearable devices; develop personalized customization, crowdsourcing design based on the Internet, New manufacturing modes such as cloud manufacturing promote the formation of R&D, manufacturing and industrial organization methods based on the dynamic perception of consumer demand.

The clear content of this action plan includes CNC machine tools, industrial robots, additive manufacturing equipment, non-standard automation equipment, smart factories, etc., and points out new production methods that accelerate the application of a new generation of information technology and advanced manufacturing technology.

Intelligent manufacturing is the empowering result of a new generation of information technology and the entire life cycle of manufacturing. Through the empowerment of industrial Internet, industrial big data, artificial intelligence and other technologies, the manufacturing industry can be intelligently produced.

At present, my country's intelligent manufacturing has entered a stage of deepening application and comprehensive promotion, and the level of intelligent manufacturing has been significantly improved. Among industry applications, the automotive manufacturing industry has the highest level of intelligent manufacturing; the intelligent manufacturing industry is showing a trend of "strong in the east and weak in the west".

Although my country is a big manufacturing country, the regional technology development is uneven, the level of informatization development is uneven, and the degree of standardization is low. With the rise of labor costs, the transfer of low-end manufacturing, the development of science and technology, and the application of artificial intelligence, China's manufacturing industry has gradually entered the stage of large-scale machine production, especially labor-intensive enterprises, promoting robot production to replace labor.

Intelligent manufacturing technology includes four levels of automation, informatization, Internet and intelligence. The development of intelligent manufacturing needs to go through four stages, namely automation (eliminating and transforming equipment with low automation level, and manufacturing intelligent equipment with high automation level) and informatization. (Products and services from physical to information network, intelligent components participate in improving product information processing capabilities), interconnection (building factory Internet of things, service network, data network, inter-factory Internet, equipment integration), intelligence (through sensors and Technology such as machine vision realizes intelligent monitoring and decision-making).

So how are the global smart manufacturing companies distributed?

From the perspective of the distribution of global leading companies, the leading smart manufacturing companies in North America are mainly concentrated in the fields of additive manufacturing and aerospace equipment. Europe gathers global leaders in the field of industrial robots and industrial control systems. Japan and South Korea have obvious advantages in automobile manufacturing. The leaders of China's smart manufacturing are mainly information giants represented by Tencent, Alibaba, and Baidu.

From the perspective of global market share distribution, North America accounts for more than 1/3 of the world in aerospace, edge computing, additive manufacturing, artificial intelligence, industrial software, virtual reality and other fields; in Europe, it is in industrial software and blockchain. It accounts for more than 30%; industries where Chinese companies have a relatively high share of the global market are concentrated in rail transit, CNC machine tools and other fields.

From the distribution of A-share listed companies, there are as many as 493 listed companies whose main business involves related industries, with a total market value of approximately 14 trillion yuan, accounting for 17% of the total A-share market value. Among them, the top three by market value are new energy vehicles, artificial intelligence, and rail transit, which together account for 40% of the entire intelligent manufacturing sector. It can be seen that although the smart manufacturing industry is relatively new, both companies and investors are enthusiastic about participating.

Intelligent manufacturing is inseparable from the support of intelligent equipment, including advanced CNC machine tools, intelligent robots equipped with new sensors, and intelligent complete production lines to realize the automation, intelligence and efficiency of the production process.

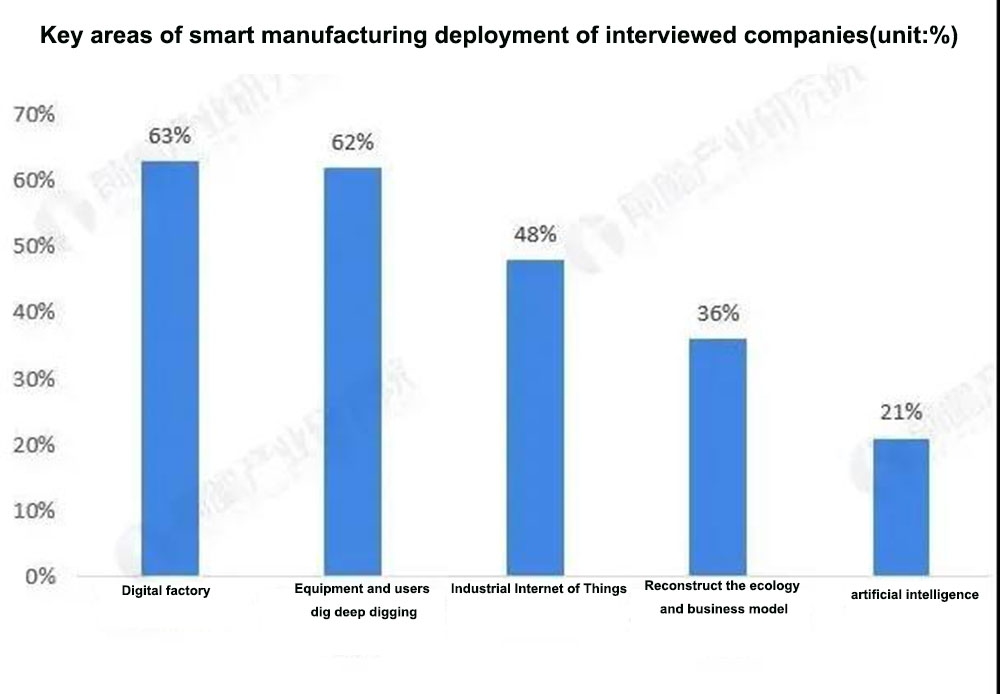

According to a Deloitte survey, the five key deployment priorities for smart manufacturing in Chinese industrial enterprises are: digital factory (63%), deep exploration of equipment and user value (62%), industrial Internet of Things (48%), and reconstruction of the ecology and business model (36) %) and artificial intelligence (21%).

From the perspective of related technologies, the related technologies that the interviewed companies are concerned about include industrial software, sensor technology, communication technology, artificial intelligence, the Internet of Things, and big data analysis.

The technologies that the interviewed companies are concerned about include industrial software, sensor technology, communication technology, artificial intelligence/robots, IoT platforms, big data, recognition technology, cloud computing, virtual manufacturing technology, 3D printing, and C2M.

Among the TOP10 industries in the national intelligent manufacturing capacity level in 2020, the intelligent manufacturing capacity level of the automobile manufacturing industry ranks in the forefront; by the electronic equipment manufacturing industry, electrical machinery and equipment manufacturing industry, etc.

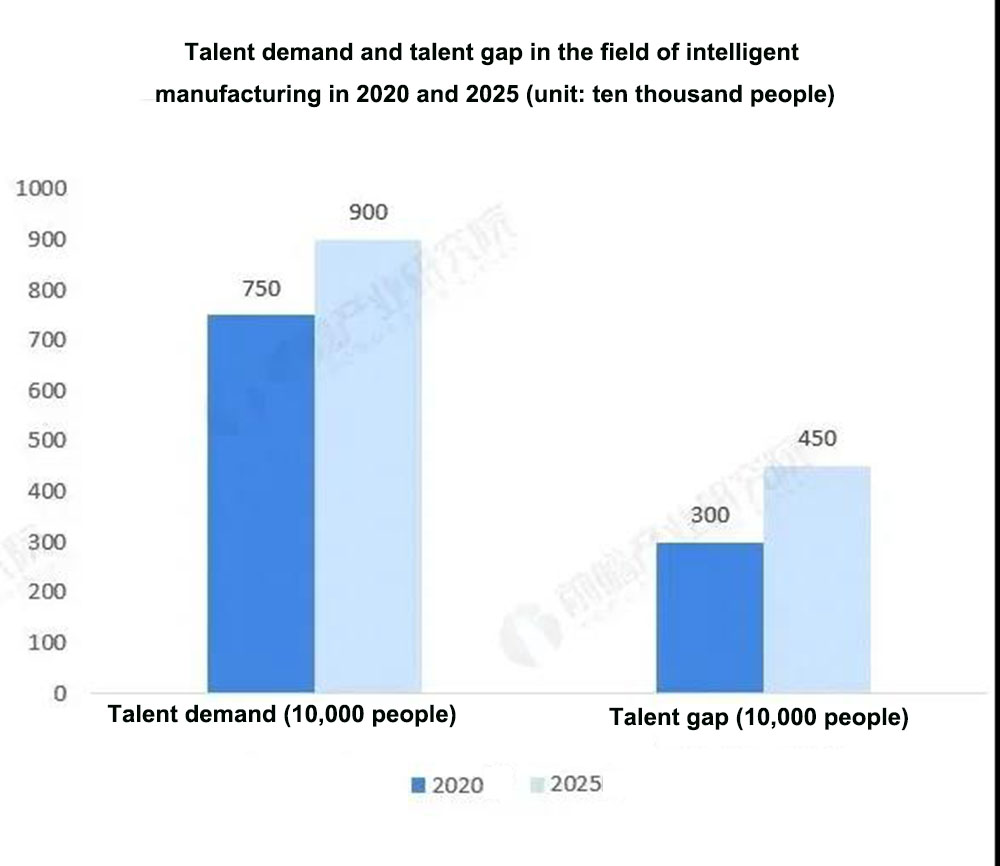

Of course, more and more manufacturing companies are also realizing that smart manufacturing is the key to improving core competitiveness, and the gap in smart manufacturing talents has become larger.

According to the data analysis of the Ministry of Human Resources and Social Security, the demand for talents in the field of intelligent manufacturing will be 9 million in 2025, and the talent gap is expected to reach 4.5 million. In the future, the training of intelligent manufacturing talents will focus more on specialization, systematization, and service enterprise internal intelligence.

In any case, in the future, any company must continue to strengthen the level of intelligent manufacturing, continuously improve the digitization and networking of equipment, strengthen digital design, build intelligent workshops, apply a large number of integrated technologies, and mine and analyze manufacturing data.

Only in this way can we take intelligent manufacturing as the main direction, promote the development of the industry to the middle and high end, and promote the high-quality economic development.