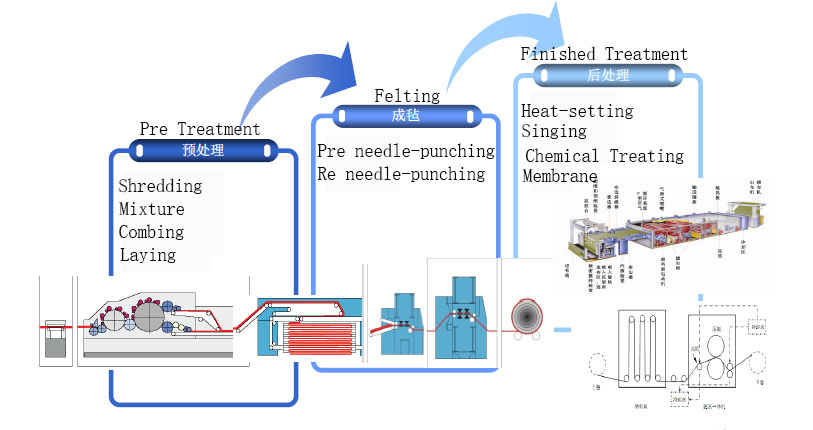

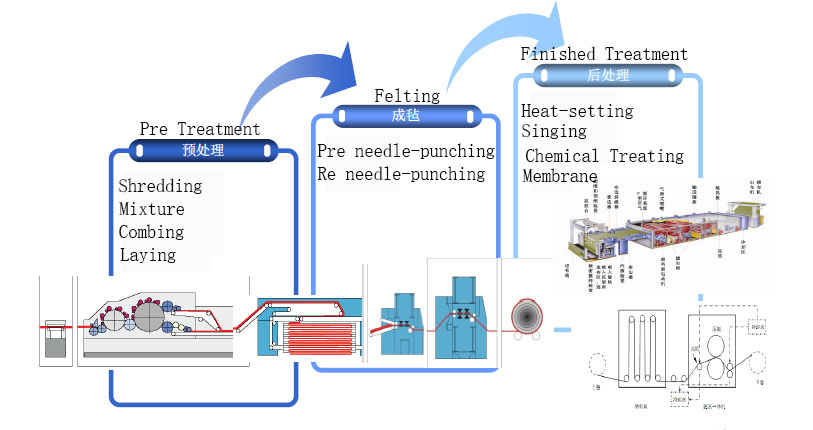

The main process of needle punching non-woven filter material for dust removal bags is: shredding - mixture - further shredding - combing - laying - needle punching - finishing - cuttng.

The fibres opened by the bale opener, although much looser compared to the fibre bales, do not yet meet the requirements of uniformity of mixing and openness and require further mixing and opening of the raw material with the blending box. The purpose of the blender is to fully open and mix the raw material.

Mixing box form according to the configuration and form of different equipment, generally divided into large bin mixers, multi-bin mixers and semi-automatic mixers.

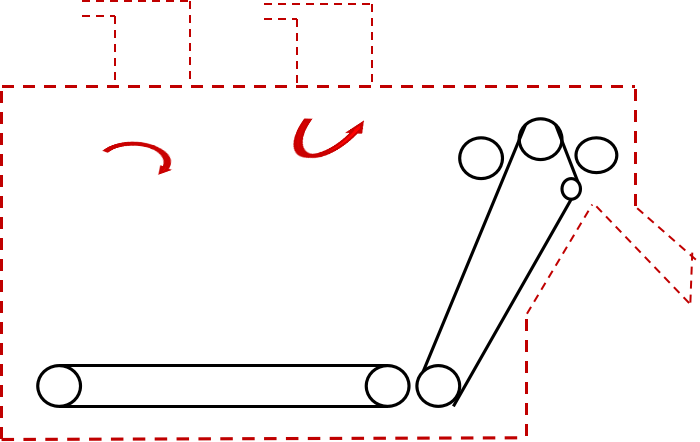

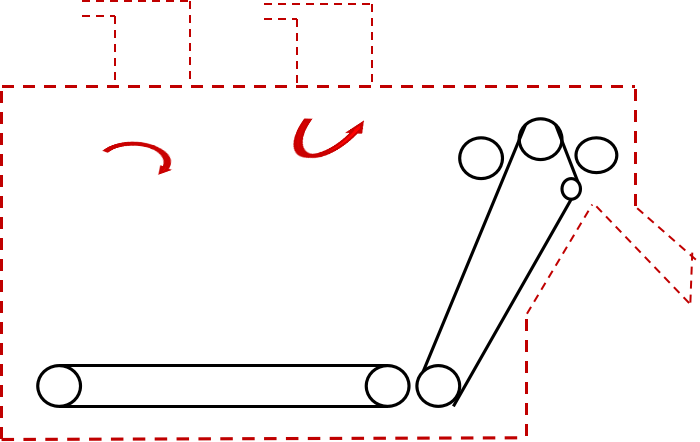

The large bin mixer is to open the bale of fibres after the bale opener, under the action of the fan through the pipe to send fibres to the cyclone separator outlet at the top of the storage bin, the fibres rotate 360° under the action of the rotating wind at the outlet, and at the same time do reciprocal movement along the longitudinal centre of the storage bin, the fibres sprayed out are evenly thrown in layers and piled up.

Yuanchen Technology always pays attention to the quality of the product first and puts quality first, and has invested in the production of needle-punched filter media by introducing the advanced needle-punching production line from Autefa, Germany. The production line is equipped with two large bin mixers to achieve sufficient mixing of the upper and lower layers of the filter material respectively, so as to prepare for the final product quality.