Difficulties and countermeasures of ultra-low emission in cement industry

Aug 04, 2021On June 3, 2020, the Ministry of Ecology and Environment issued the "Opinions on Actively Servicing and Implementing the "Six Guarantees" Tasks under the Prerequisite of Normalization of Epidemic Prevention and Control, and Resolutely Winning the Battle of Pollution Prevention and Control" (Huanting [2020] No. 27).

In the "Opinions", certain prerequisites have been added to the ultra-low emission transformation of the cement industry: areas with larger production capacity; measures to local conditions; research and development, and the combat mission of winning the battle against pollution prevention has officially joined the cement industry. emission. In fact, major cement provinces in key regions such as Hebei, Henan, Anhui, Zhejiang, etc. have already taken the lead in the country in carrying out ultra-low emission transformation work in the cement industry. Low-emission retrofit projects, and achieved ultra-low emissions.

|

The latest air pollutant emission standards for the cement industry in some provinces and cities (mg/m3) |

||||

|

area |

particulates |

Sulfur dioxide |

Nitrogen oxides |

Complete time |

|

Zhejiang |

10 |

35 |

100 |

End of 2022 |

|

|

10 |

35 |

50 |

End of June 2025 |

|

Hebei |

10 |

30 |

50 |

Oct 11th,2021 |

|

Henan |

10 |

35 |

100 |

End of 2022 |

|

|

10 |

20 |

50 |

Strive to achieve |

|

Anhui |

10 |

50 |

100 |

Oct 1st,2020 |

|

Shanxi |

20 |

20 |

260 |

Datong,Xinzhou,Shuo Zhou existing enterprise |

|

|

10 |

30 |

200 |

Jinzhong City,Lvliang City,Linfen City,Yuancheng City,Taiyuan,Yangquan,Changzhi,Jincheng |

|

Hainan |

10 |

100 |

200 |

Before Dec 31st,2021 |

|

Handan |

10 |

50 |

50 |

/ |

|

Tangshan |

10 |

30 |

50 |

/ |

|

Xingtai |

10 |

50 |

50 |

/ |

|

Guangan |

10 |

50 |

100 |

/ |

|

Jinhua |

10 |

35 |

100 |

Within two years |

The major changes in the cement industry's ultra-low emissions have also spawned the emergence of new technologies for dust removal, desulfurization, and denitrification, providing technical support for the cement industry to more efficiently and stabilize the deep emission reduction of pollutants. Desulfurization and dust removal technology processes have been able to meet today's standard requirements, and nitrogen oxides (NOx) are the biggest problem facing ultra-low emission transformation. The characteristics of NOx emissions in the cement industry are high concentration, high dust content and high viscosity, which make it difficult to remove nitrogen oxides from cement clinker production lines.

There are two types of denitration technologies commonly used in the industry: SNCR and SCR:

SNCR technology:

1. Low-nitrogen technological transformation + SNCR precision denitrification technology: This technology has been successfully applied in a 7500t/d clinker production line of a cement company in Zhejiang, and can stably control NOx emissions within 100mg/Nm3.

2. SNCR+ ion generator denitration technology: Using this technology in a 5500t/d clinker production line of a cement plant in Henan, the final NOx emission concentration is ≤30 mg/Nm3, and the ammonia escape is less than 5ppm.

3. Staged combustion + SNCR + steam catalytic combustion technology: a typical representative is the 5000t/d line of a cement company in Jiangsu.

SCR technology:

1. High temperature and medium dust: High temperature electric dust removal + SCR technology: This technical solution is well adapted to the characteristics of the cement industry, ensuring catalyst efficiency at high temperature, removing dust to alleviate the clogging, poisoning, and abrasion problems of the catalyst, and reducing the burden of SCR.

2. High temperature and high dust: SCR denitration technology: The first domestically made high temperature and high dust SCR denitrification project independently developed by a domestic cement group company has successfully entered the trial operation stage, and the NOx emission concentration at the kiln tail is stably controlled within 50mg/m3.

3. High temperature and low dust: "High temperature bag dust removal + SCR" technology: The high temperature electric bag (SCR) integrated dust and nitrate denitrification system adopted by a cement company in Henan was put into operation, and a new technology solution was developed for ultra-low emissions in the cement industry. The initial operation effect of the project was established: the system pressure loss was 580-630Pa, the dust emission was less than 10mg, NOx was less than 20mg/m3, the amount of ammonia injection was less than 0.2m3/h, and the ammonia escape was less than 3ppm.

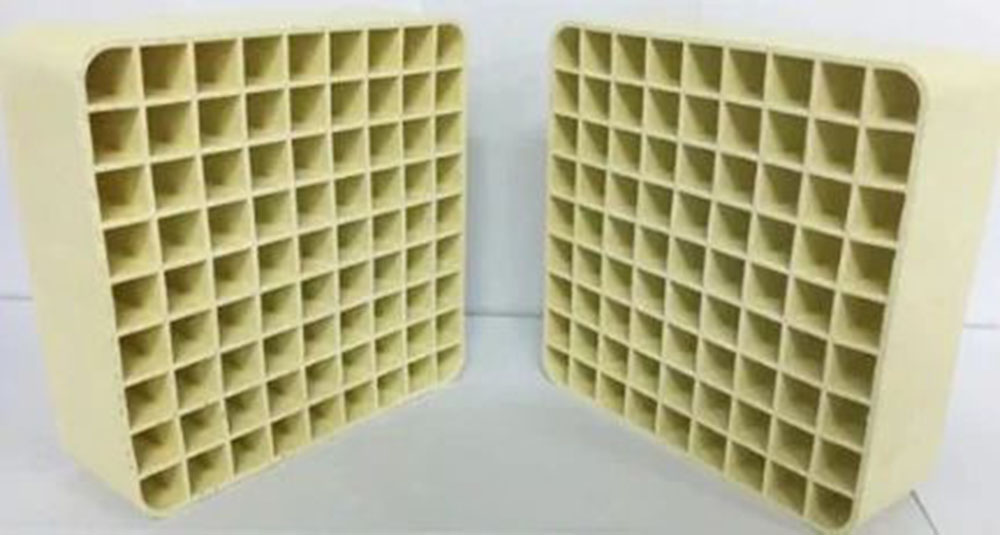

Yuanchen Technology has a number of innovations in technology and products in cement kiln flue gas dust removal and denitration, including Noda® cement kiln special series filter material, alkali-resistant SCR denitrification technology, high dust and wear-resistant SCR denitrification technology, and low-hole SCR Denitrification technology and "dust nitrate filter" dedusting and denitrification catalytic filter material. In view of the characteristics of cement kiln flue gas operating conditions, the selection and design of cement denitration catalysts should comprehensively consider the operating conditions of the product application, in terms of wear resistance, anti-blocking, resistance to alkali metal/alkaline earth metal/heavy metal poisoning, resistance to sulfur conversion, and prevention of super The adhesion of fine dust improves the physical and chemical properties of the denitration catalyst.

Founded in 2019, Yuanchen Institute of Science and Technology Innovation is a research institute dedicated to technological innovation and driven by corporate and social needs. It is a think tank for Yuanchen Technology’s global development strategy, based on basic science and applied technology research.

The research institute specially developed an anti-blocking 9-hole honeycomb denitrification catalyst for flue gas denitration in the cement industry. By adding ultra-fine roasting aids in the catalyst preparation process, the local strength of the honeycomb denitrification catalyst tip is improved by the principle of lattice doping to improve the resistance. Grinding performance; increase the amount of acid on the catalyst surface, improve the dispersion of active components, and add additives to induce alkali/alkaline earth metal curing to improve the alkali/alkaline earth metal poisoning resistance of the catalyst, and then add WO3 to improve the sulfur resistance of the catalyst.

At present, the research institute is actively conducting research and development work on the anti-heavy metal poisoning and anti-adhesion of ultrafine dust for cement denitration catalysts.