Demystifying AR-21 gel Silicon-based Ultra-wear-resistant Filter Material

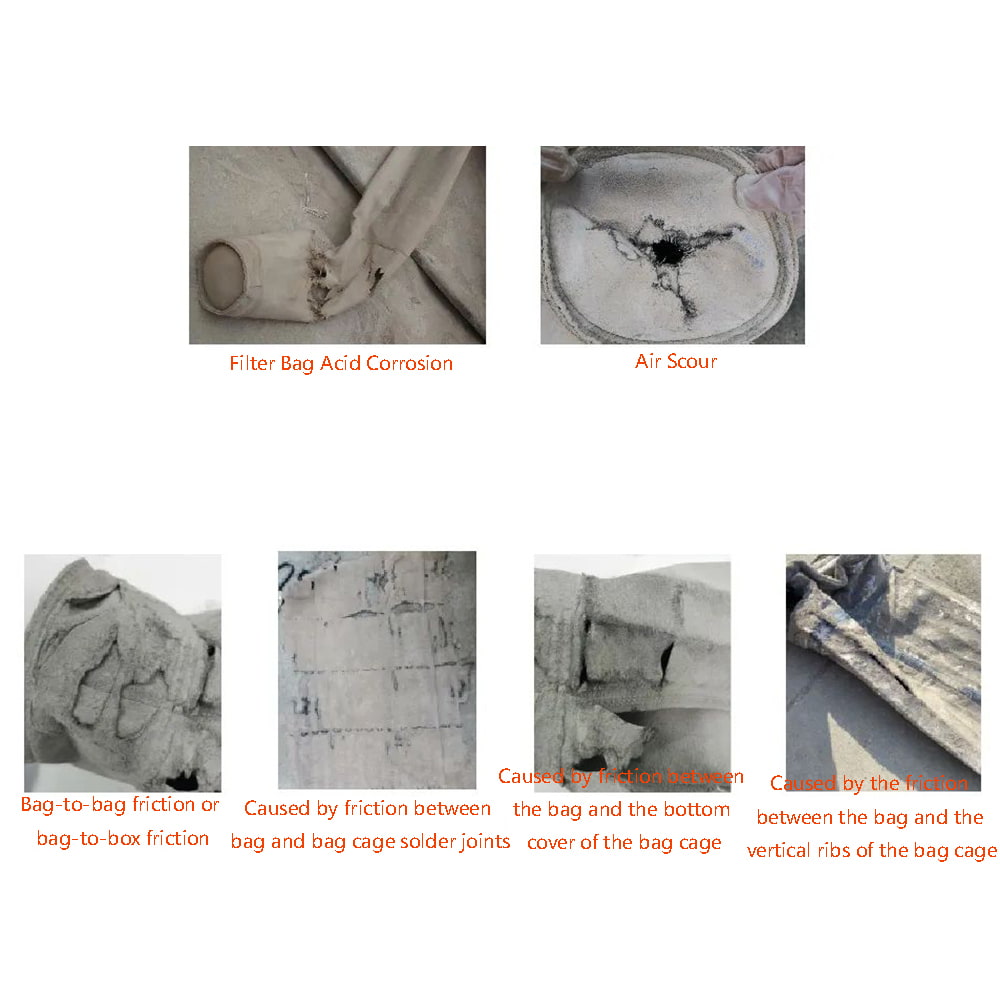

Mar 22, 2022The reasons for the damage of filter bags during operation include chemical damage (acid-base corrosion, oxidation and hydrolysis, etc.), air scouring (inside and outside the bag) and mechanical friction.

According to the failure detection and analysis results of old bags of Anhui Confair Testing Technology Co., Ltd. (CNAS, CMA) in 2021, as shown in Figure below, except for the phenomenon of condensation and sticking bags caused by working conditions, the number of damaged filter bags is the largest. The main reason for the damage of the filter bag is the friction between the filter bag and the filter bag.

The filter bag damage caused by the friction between the bags accounts for the highest proportion, accounting for 70% of the broken bags; therefore, improving the wear resistance of the filter bags by effective methods will effectively delay or avoid the damage and failure caused by friction, and prolong the filtering time. service life of the bag.

In order to solve customers' pain points and fundamentally improve the wear resistance of filter media, Yuanchen Technology has the following technical advantages:

1. Double-layer bag bottom reinforcement technology;

2. AR-21 gel silicon-based high wear-resistant filter material.

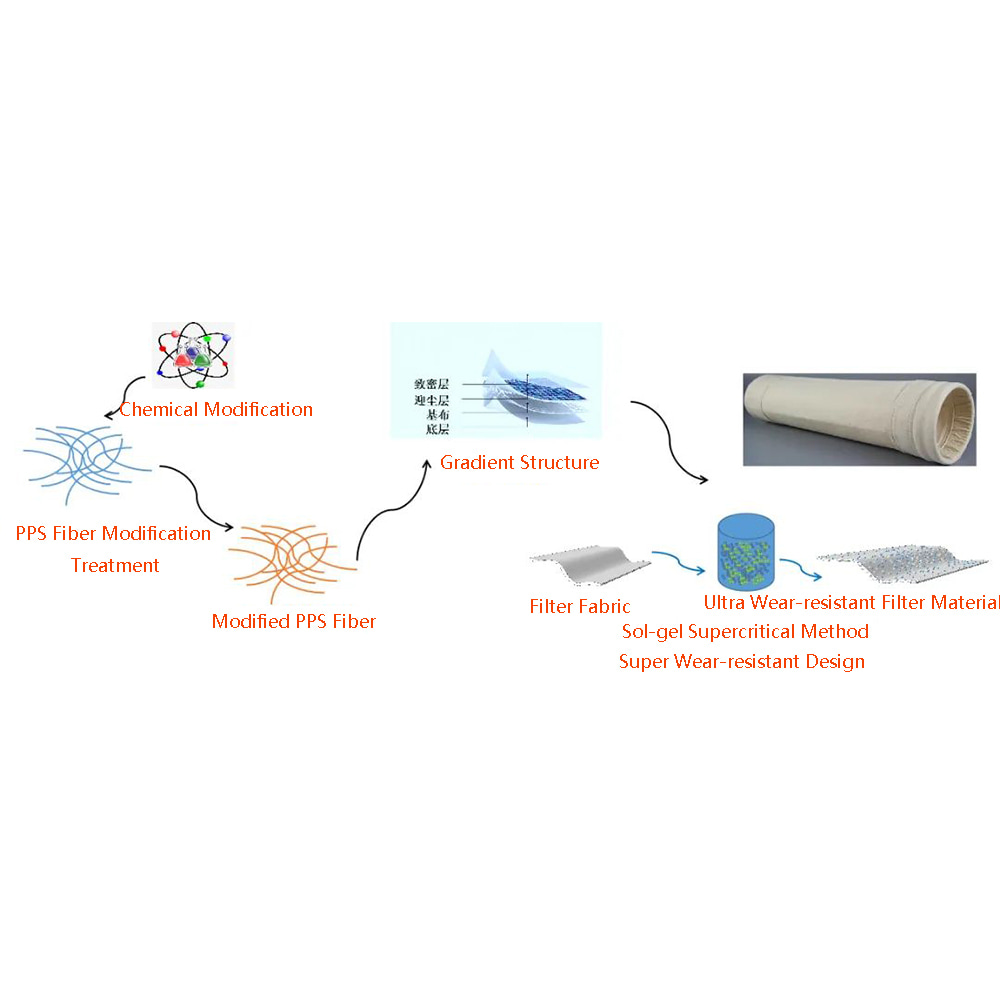

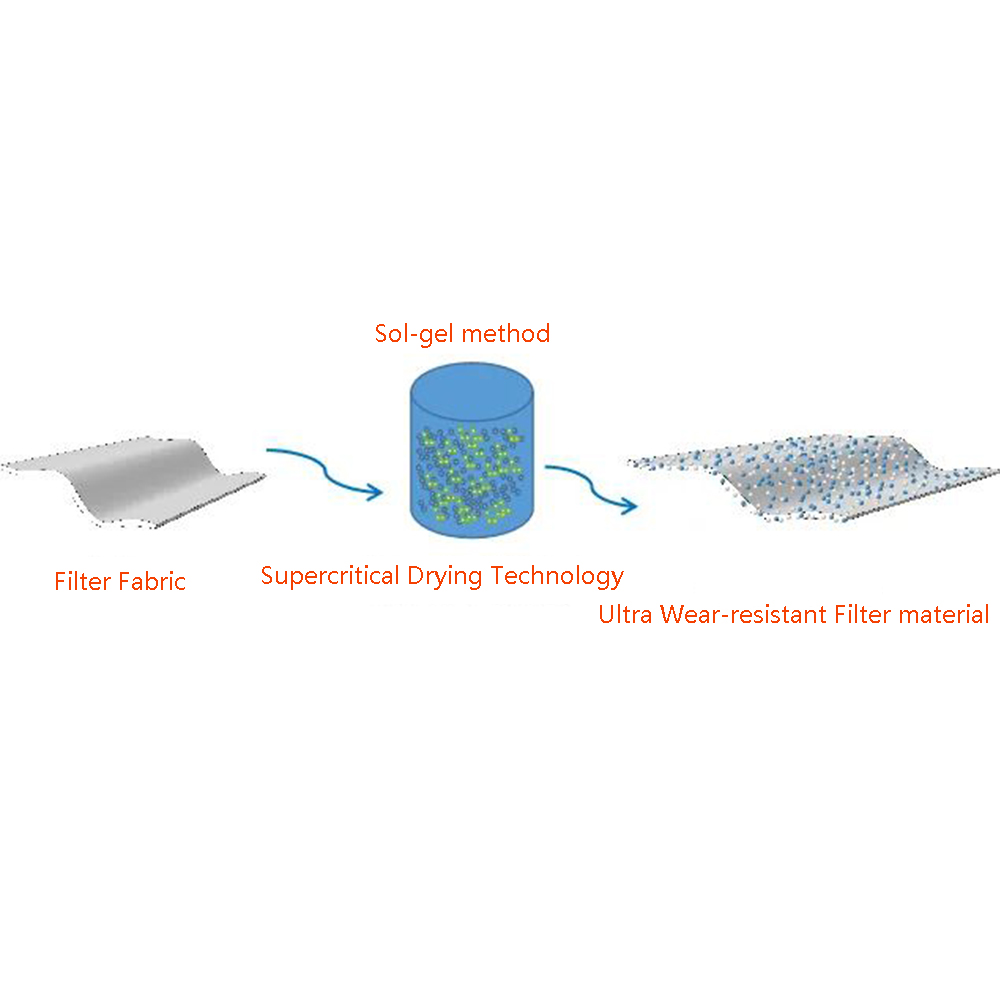

Yuanchen Technology adopts modified fiber technology, premixed gradient technology and sol-gel-supercritical drying technology, etc. As shown in the figure below, it has developed AR-21 gel silicon-based high wear-resistant filter material, which can adapt to different working conditions The use requirements of the filter material have fundamentally improved the wear resistance of the filter material.

The technical innovations of AR-21 gel silicon-based high wear-resistant filter material are:

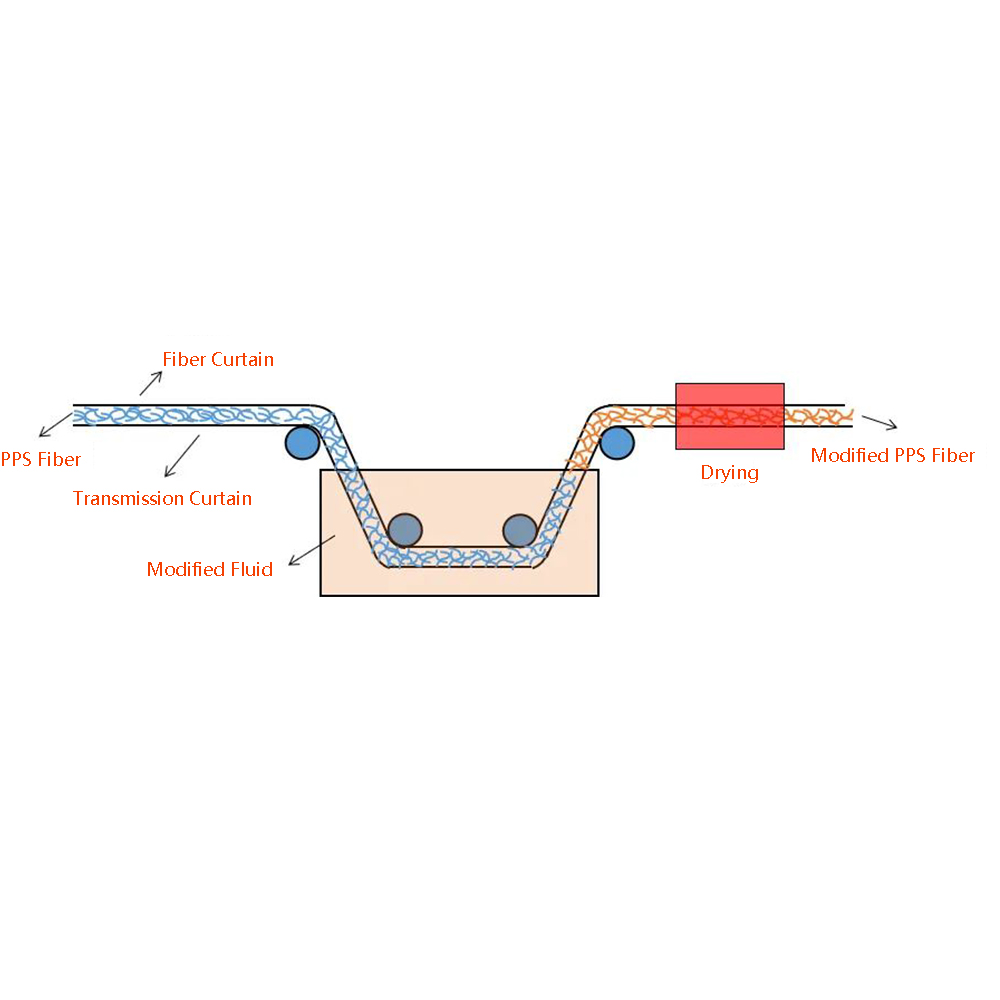

1. Modified PPS fiber: By modifying the fiber to improve its tensile properties, the filter material has excellent breaking strength and breaking elongation;

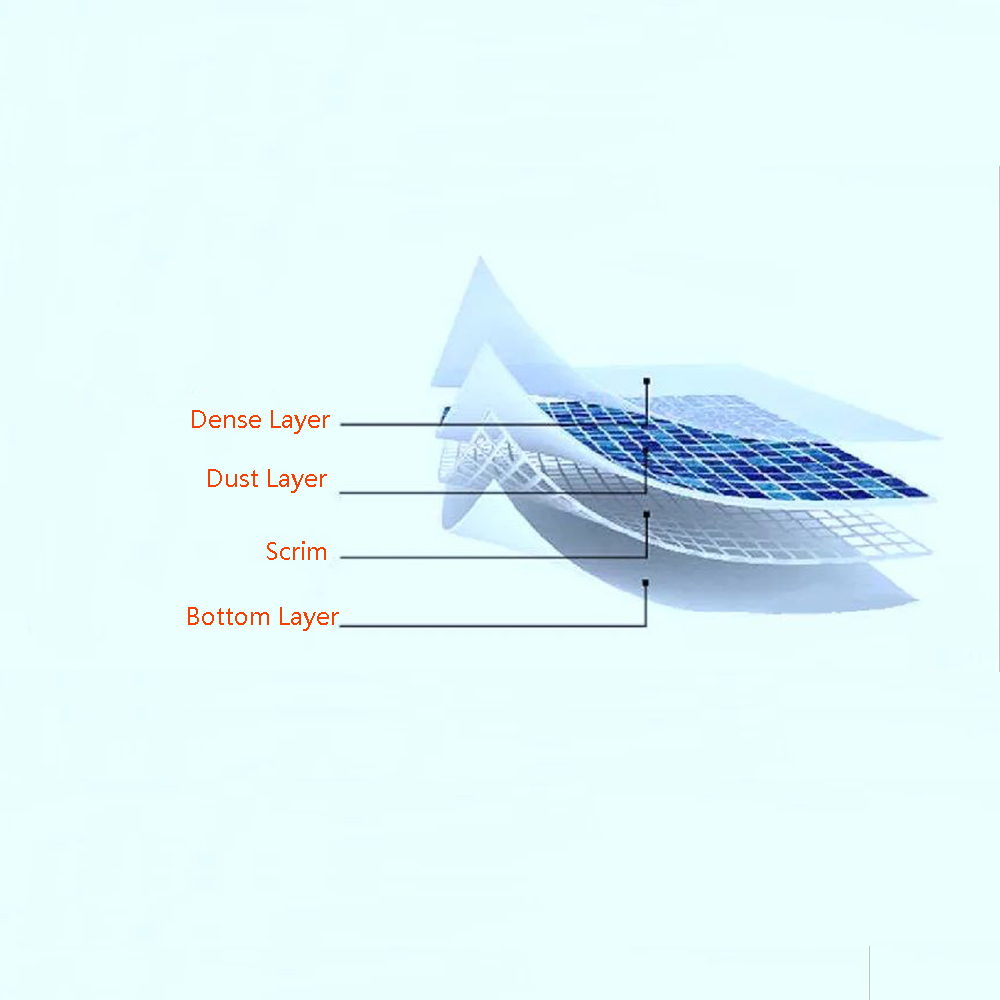

2. "Pre-mixed gradient" technology, designed a pre-mixed-fineness/density graded combination of asymmetric gradient structure filter material, formed by ultra-fine fibers to form a dense layer and the bottom layer to form a density gradient structure to achieve high-precision filtration, in non-film-coated Under the circumstance, it can meet the ultra-clean emission of dust particles (< 5mg/Nm3), and the operating resistance of the filter bag is lower than that of the film-coated filter material, which truly realizes "high efficiency and low resistance";

3. Super wear-resistant technology, using sol-gel method, nano-scale silicon-based particles are aggregated with each other to form a nano-porous network structure, and the network pores are filled with gaseous dispersion medium, and supercritical drying technology is used to make gel silicon-based materials. , Membrane treatment technology to form ultra-wear-resistant filter material.

The tensile properties of AR-21 gel silicon-based high wear-resistant filter material are better than that of ordinary gradient filter material, and the fluctuation of breaking strength is small.

According to GBT 21196.2-2007 Textiles - Determination of abrasion resistance of fabrics by Martindale method - Part 2: Determination of sample breakage, the abrasion resistance of AR-21 gel silicon-based high abrasion resistant filter material was determined.

The wear resistance index of AR-21 gel silicon-based ultra-wear-resistant filter material increases exponentially, effectively resisting the damage and failure of the filter bag caused by friction.

The super wear-resistant technology independently developed by Yuanchen Technology is suitable for various fibers, various filter materials and various working conditions. AR-21 gel silicon-based high wear-resistant filter material can fundamentally effectively improve the wear resistance of the filter material. , which will effectively delay or avoid damage and failure caused by friction and prolong the service life of the filter bag.