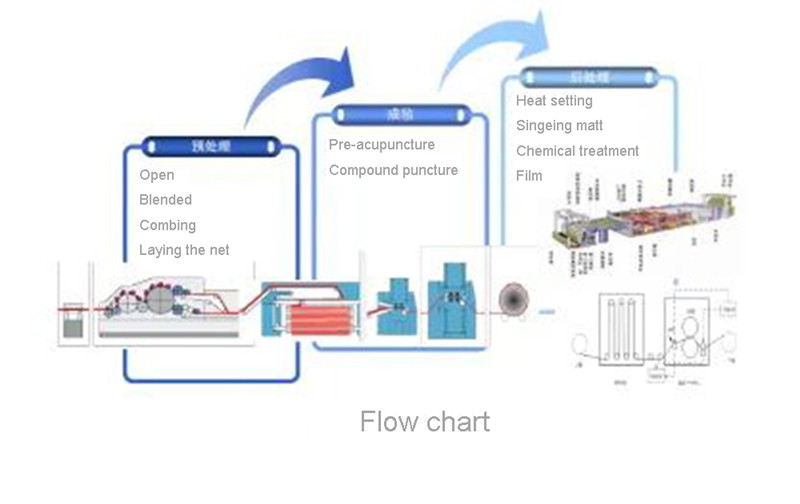

The main technological process of the needle punched non-woven filter material for bag filter is: opening-mixing-fine opening-carding-netting-needle punching-finishing-slitting bag making.

Carding is the most important step in the pre-spinning process of textiles. The uniformity of the carded web directly affects the quality of the finished product. The function of carding is to process the fully opened fibers into a uniform thin fiber web.

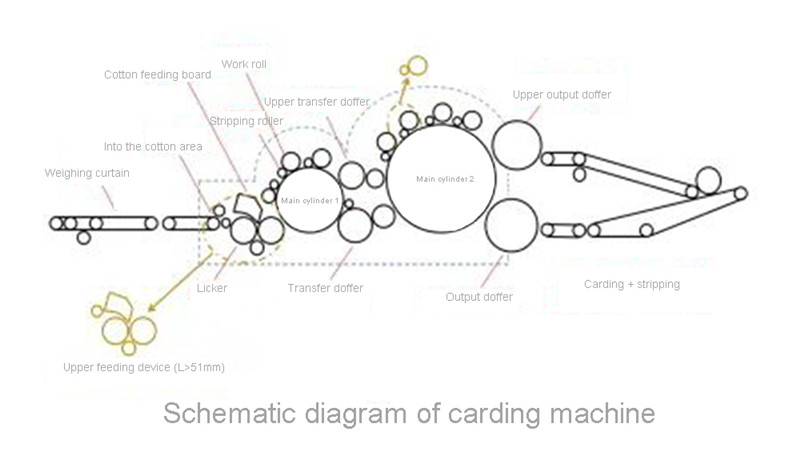

There are many types of carding machines, and the carding machine for processing the non-woven bag filter material is a roller type. The continuous belt weighing curtain is used for auto-leveling between the cotton feeding box and the carding machine to keep the amount of fiber fed into the carding machine consistent.

For the processing of chemical fibers, the carding process mainly includes three basic actions: carding, stripping and lifting. Generally, carding is mainly used between doffer and cylinder, and peeling is mainly used between doffer, work roll and stripping roller. On a carding machine, a work roll and a stripping roller are called a carding unit. Generally, there are 5 to 8 carding units on a carding machine. The work rolls not only play the role of carding, but also play a role in uniformity and refinement.

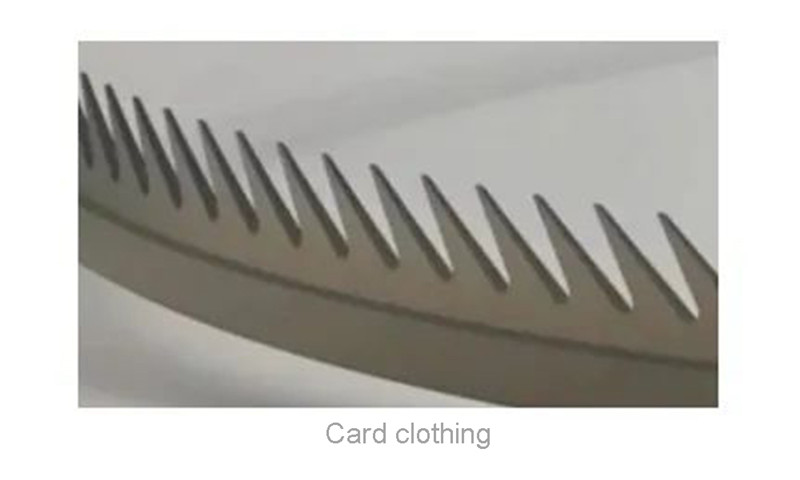

The carding process is to use the card clothing wrapped on the rollers of the carding machine to card the fibers. In the carding process, the entangled and crimped fiber bundles are separated into single fibers, so that the fibers are straight and parallel. The card clothing used in the non-woven filter carding machine is a metal card clothing.

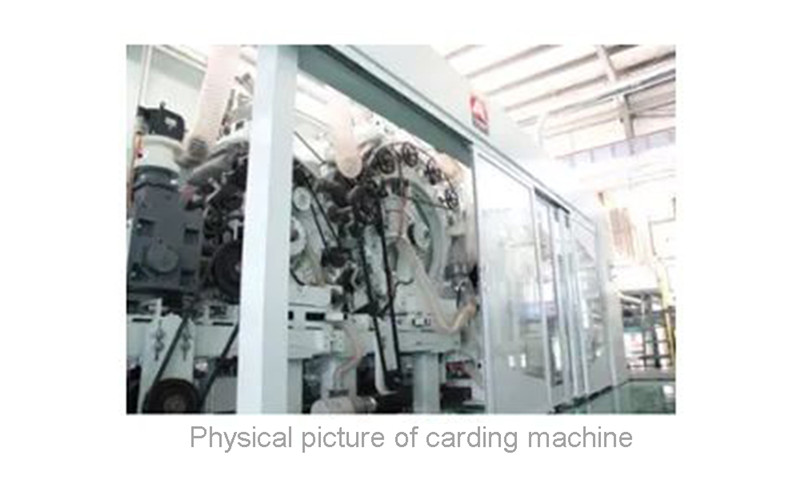

Yuanchen Technology always pays attention to product quality and quality first, and invests in the introduction of advanced Autefa acupuncture production line from Germany for the production of acupuncture filter materials. The production line is equipped with two carding machines, which respectively realize the carding of the dust removal filter material surface layer, the bottom layer fiber and the output of the fiber web, which is a key step for the quality control of the final product.