Application of denitration catalyst in waste incineration industry

Jan 20, 2022Comparison of incinerator tail gas denitrification processes

The tail gas of the waste incinerator is reduced to 130~150℃ after dry/semi-dry deacidification (sulfur) and bag dust removal. At present, the activation temperature of medium and low temperature denitrification catalysts on the market is above 180℃, so it is necessary to supplement the exhaust gas. The denitrification can be carried out after the temperature rises. The general process route is to add a GGH heat exchanger, and then heat the heat source to increase the temperature of the flue gas to about 200 °C for denitrification. Therefore, the process is complicated, the investment in equipment engineering is large, and the operation cost of temperature rise is high. very high.

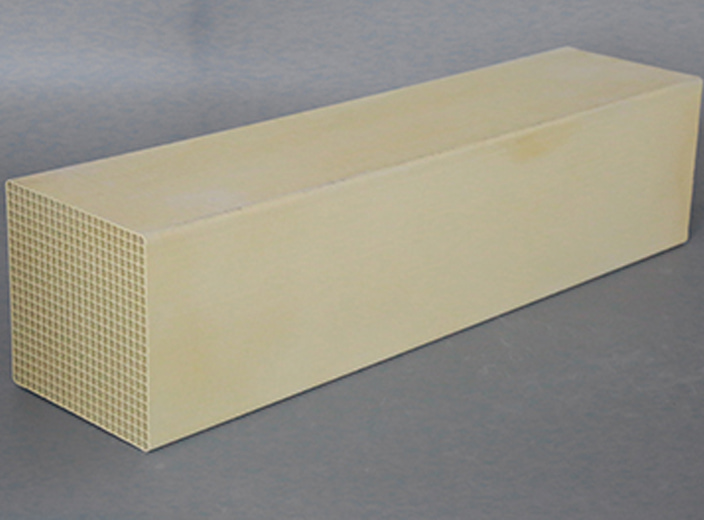

The temperature activity range of the ultra-low temperature denitrification catalyst is 130~180℃, which can be directly denitrified under the condition of 150℃ exhaust gas temperature after bag dust removal, no need for supplementary combustion heat exchange to heat up, the process is simple and no heating cost, and basically has no impact on the original system , and the flue gas resistance is low, which can meet the ultra-low and ultra-clean emission requirements.