Application of denitration catalyst in natural gas boiler

Jan 19, 2022At present, the functions of natural gas boilers are mainly heating, supplemented by steam production and power generation. Natural gas is recognized as a clean energy. In the early stage, it was believed that the boiler did not need environmental protection exhaust gas treatment facilities. However, at this stage, there are policy requirements for denitrification. mg/Nm3, and the emission standard in special areas is lower than 30 mg/Nm3. Jiangsu Province has formulated a solicitation standard for emission lower than 10 mg/Nm3. The current main technology is low-nitrogen combustion technology, that is, the burner is changed to low-nitrogen The burner basically meets the emission standard of 30 mg/Nm3 of NOx in the exhaust gas. The low-nitrogen combustion technology controls the combustion temperature and oxygen content to suppress the production of nitrogen oxides and control the value of nitrogen oxides in the flue gas. In this case, the thermal efficiency of the system will be reduced by about 5~10%. operating costs. Taking a 50t boiler as an example, after the low-nitrogen combustion system is installed, the boiler will consume nearly 3 million yuan of natural gas every year under the same steam condition. , carbon neutral").

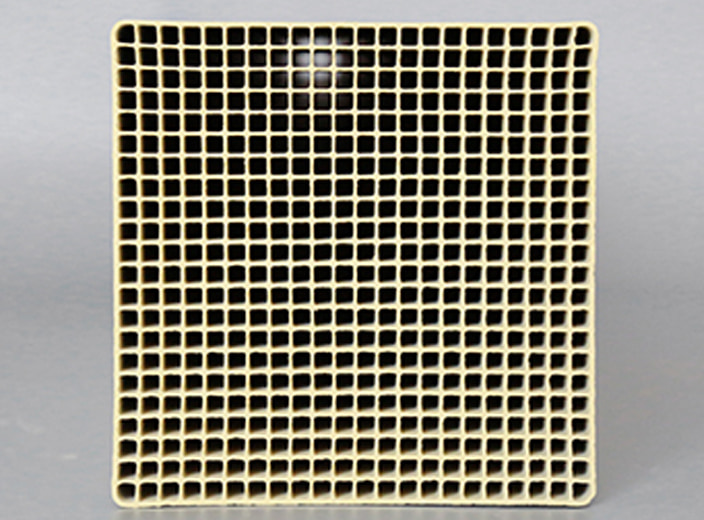

Reaction principle: Selective catalytic reduction (SCR) method, that is, using ammonia as a reducing agent in a reactor equipped with a catalyst to remove nitrogen oxides. Nitrogen oxides in flue gas generally consist of about 95% NO and 5% NO2 by volume. The denitration reaction is converted into molecular nitrogen and water vapor according to the following basic reactions. The denitration reactor (that is, the denitration catalyst layer) is arranged between the boiler economizer and the air preheater. The inlet of the denitration reactor is connected with the outlet of the boiler economizer through the flue, and the outlet is connected with the air preheater through the flue. The flue gas vertically passes through the denitration catalyst layer of the denitration reactor from top to bottom. At this time, the flue gas temperature is about 280-420 °C, which is the best reaction temperature for the catalytic reduction reaction of denitration.

Anhui Yuanchen Environmental Protection Science and Technology Co., Ltd. ("Yuanchen Technology" for short) is a high-tech enterprise integrating R&D, production and sales of dust removal filter bags and denitration catalysts(SCR Catalyst). Dust filter bags (mainly PPS, PTFE, P84 and composite series filter materials) and SCR denitration catalysts have been widely used in cement, steel, glass furnaces, waste incineration power generation, biomass power generation, non-ferrous metal smelting and other industries! In the future, Yuanchen Technology will be guided by "becoming a guardian of the global ecological environment", always take root in environmental protection, and adhere to the great cause of protecting the blue sky and white clouds. Leveraging the national ecological civilization construction pattern, we will continue to deepen technology, optimize management, strengthen brands, refine industries, consolidate advantages, and create synergistic value for the industry through comprehensive overall management and services.