Application characteristics of new bag filter (2)

Jan 21, 2022(7) If the new type of bag filter is designed according to independent equipment, its structure design can also be made into a combined structure, which has good adaptability to the changes and expansion of engineering projects. The new type of bag filter can increase or decrease the dust removal combined unit according to the change of the flue gas volume of the project. Especially for projects with foreseeable changes in the construction scale, it is not necessary to reserve the construction site of the dust collector in the later stage. Increase or decrease the number of layers of the dust removal unit to achieve economical and practical upgrades on the spot;

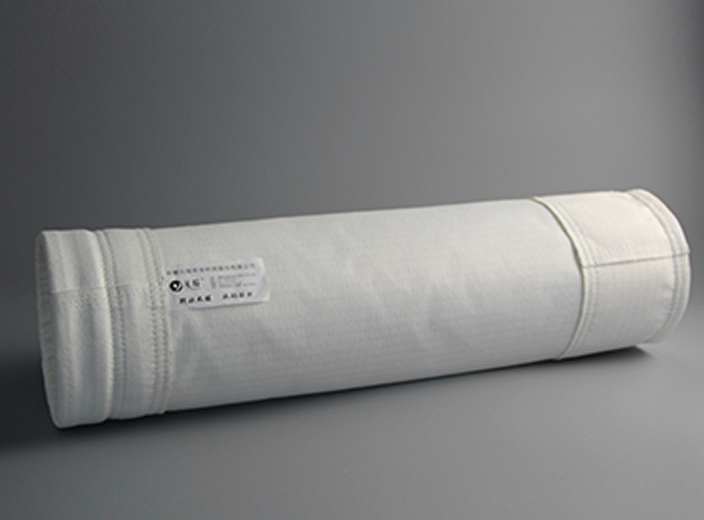

(8) The internal structure of the new type of bag filter is more complicated than that of the traditional low-pressure long-bag filter, and the dust removal bags are more closely arranged, and the dust accumulation effect of the filter structure is relatively strong. Liquidity is better, which is its weakness. For this weakness, attention should be paid to the inclination of the wall in manufacturing, the moisture content of flue gas should be controlled during operation, and the temperature of dust should be maintained.

In general, multi-layer bag filter has obvious advantages over traditional filter in terms of floor space, convenience of operation and maintenance, project construction and operation cost, and equipment variability.

The traditional bag filter has only a single-layer layout, and the space height is often very small. In the layout environment of those tall boilers and other supporting equipment, it appears to be very small; however, its horizontal footprint is relatively large, especially when dealing with large air volumes. The arrangement structure of the dust collector and its air duct is more complicated. The development of a new type of bag filter will significantly improve this, and the same footprint can fully expand the processing capacity of the filter. At the same time, it can also be seen from the above analysis that the multi-layer design of the bag filter brings a series of advantages to the filter in terms of construction, operation and maintenance. The multi-layer design of the bag filter is a new practical exploration in the mechanical structure of the filter. Similar research and rational development can also be done for other types of dust collectors.