Analysis of the advantages and disadvantages of the most commonly used desulfurization technologies

Mar 11, 2021At present, the commonly used flue gas desulfurization methods at home and abroad can be divided into three types of desulfurization processes: wet, semi-dry, and dry according to whether water is added during the desulfurization process and the dry and wet form of the desulfurization product.

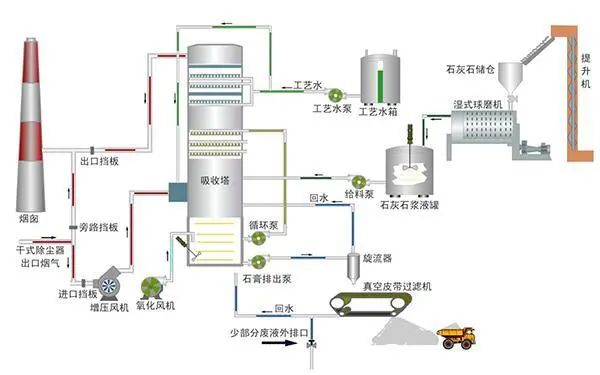

1. Wet desulfurization

Advantages: gas-liquid reaction, fast reaction speed, high desulfurization efficiency, generally higher than 90%, mature technology and wide application. The technology is relatively mature, and the production and operation are safe and reliable, accounting for more than 80% of the total installed capacity of desulfurization.

Disadvantages: The product is liquid or sludge, which is difficult to handle, the equipment is severely corrosive, the flue gas needs to be reheated after washing, the energy consumption is high, the area is large, and the investment and operating costs are high. The system is complex, the equipment is huge, the water consumption is large, and the one-time investment is high. It is generally suitable for large-scale power plants.

Technical route: limestone/lime-gypsum method, indirect limestone-gypsum method, lemon absorption method, etc.

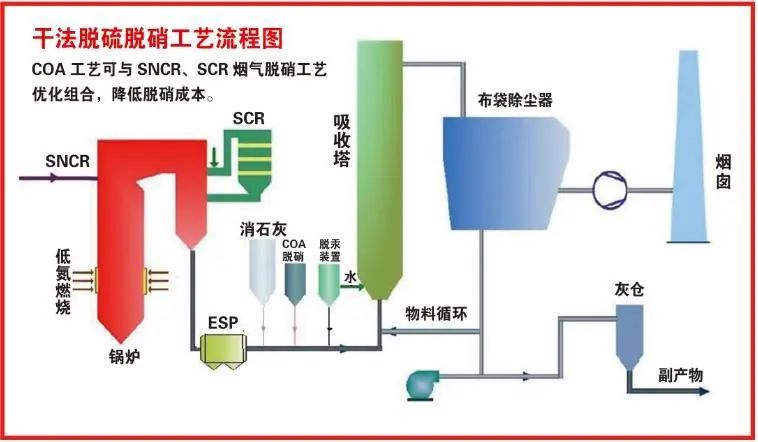

2. Dry desulfurization

Advantages: gas-solid reaction, compared with wet desulfurization system, the equipment is simple, the area is small, the investment and operating costs are lower, the operation is convenient, the energy consumption is low, the product is easy to handle, and there is no sewage treatment system.

Disadvantages: slow reaction speed, low desulfurization rate, advanced up to 60-80%. The desulfurization efficiency is low, the absorbent utilization rate is low, the abrasion and fouling phenomenon are more serious, the equipment maintenance is more difficult, the stability and reliability of the equipment operation are not high, and the service life is short.

Technical route: activated carbon adsorption method, electron beam radiation method, charged dry absorbent injection method, metal oxide desulfurization method, etc.

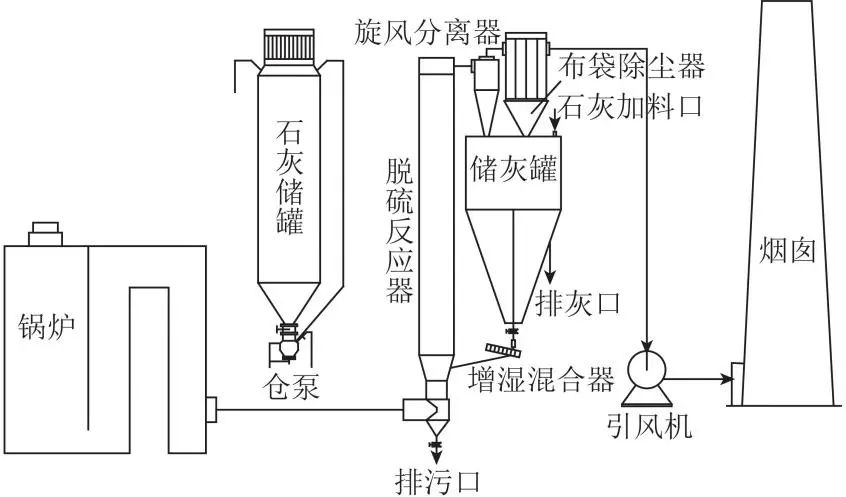

3. Semi-dry desulfurization

Semi-dry desulfurization includes spray drying desulfurization, semi-dry and semi-wet desulfurization, powder-particle spouted bed desulfurization, flue jet desulfurization, etc..

1. Spray drying method

Disperse the absorbent into very small mist droplets by the force of machinery or air flow. The mist droplets and the flue gas form a relatively large contact surface area. A kind of heat exchange, mass transfer and integration between the gas and liquid phases occurs. Desulfurization method of chemical reaction. Commonly used absorbents are lye, lime milk, limestone slurry, etc. At present, most devices use lime milk as absorbent. Under normal circumstances, the desulfurization rate of this method is 65%-85%.

Advantages: Desulfurization is carried out in the three-phase state of gas, liquid, and solid. The process equipment is simple. The product is dry CaSO3 and CaSO4, which is easy to handle, has no serious equipment corrosion and blockage, and consumes less water.

Disadvantages: The automation requirements are relatively high, the amount of absorbent is difficult to control, and the absorption efficiency is not very high.

2. Semi-dry and semi-wet method

A desulfurization method between wet and dry methods, its desulfurization efficiency and desulfurization agent utilization rate and other parameters are also between the two, this method is mainly suitable for the flue gas treatment of small and medium boilers.

Features: low investment, low operating cost, although the desulfurization rate is lower than that of wet desulfurization technology, it can still reach 70%, and it is less corrosive, occupies less area, and reliable process. Compared with the wet desulfurization system, the semi-dry and semi-wet desulfurization system commonly used in the industry eliminates the pulping system, and changes the spraying of the aqueous solution in the wet desulfurization system to the injection of CaO or Ca(OH)2 powder and water fog. Compared with the dry desulfurization system, it overcomes the disadvantages of low reaction efficiency and long reaction time of the calcium spraying method SO2 and CaO in the furnace, improves the utilization rate of the desulfurization agent, and the process is simple.

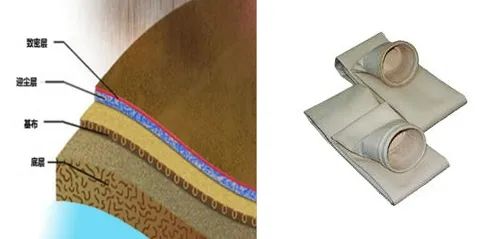

3.Yuanchen technology semi-dry special filter material

After adopting semi-dry desulfurization, the working condition of the bag filter is different from the post-desulfurization process. The sulfur oxides in the flue gas are removed, but the flue gas humidity and dust concentration will increase.

Yuanchen Technology has specially developed an ultra-fine surface layer gradient filter material for the semi-dry steel sintering process. Using the measured flow field parameters as the boundary conditions, the CFD technology is used to simulate and optimize the layered combination parameters of fibers of different diameters, and the denier/density grading combination is adopted. The gradient structure, the design of the gradient layered structure is conducive to the formation of filter cake, the dust collection efficiency is high, and the equipment operation resistance is low.

The advantages and characteristics of the product are: (1) Excellent waterproof and oil-proof performance, effectively resisting high moisture content; (2) Easy to clean dust, effective resistance guarantee; (3) Excellent erosion resistance and abrasion resistance, effectively improving the service life; (4) ) High filtration accuracy, up to 5mg/Nm3 emission requirement at the outlet of the dust collector can be achieved.