A brief analysis of the comparative experimental research on the folding resistance and strength characteristics of filter media

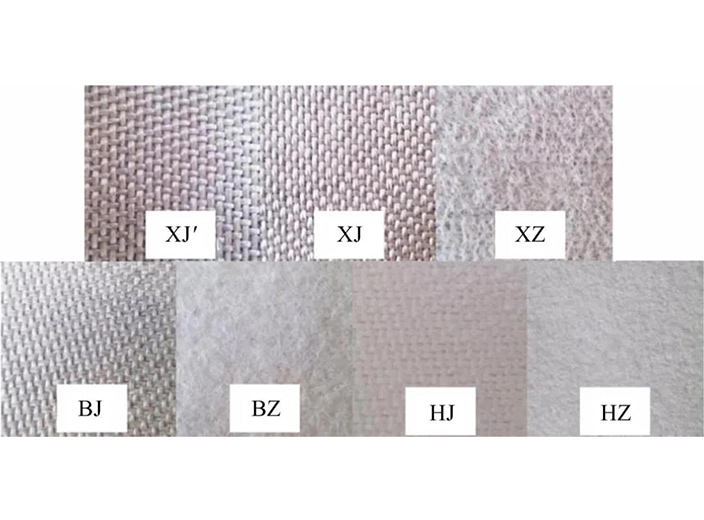

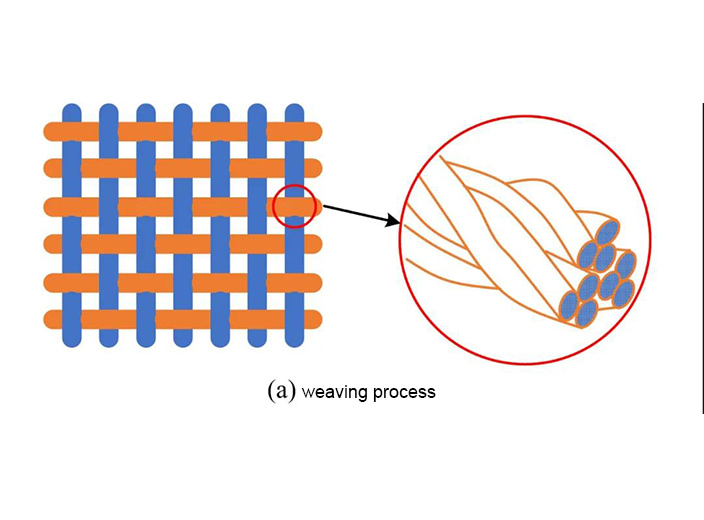

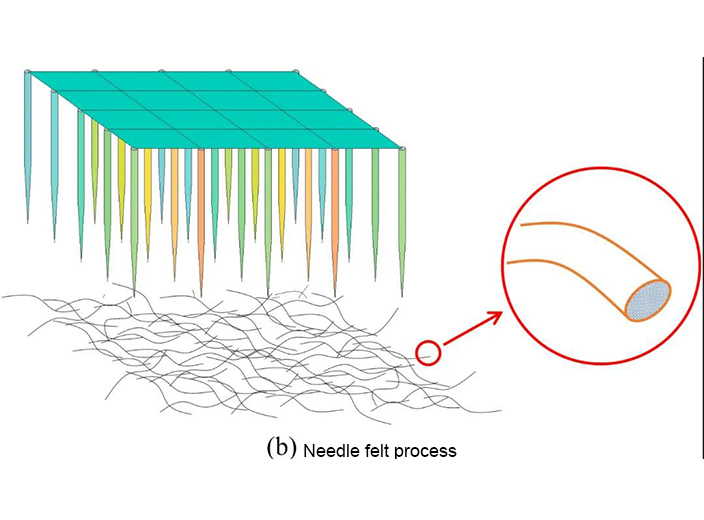

Feb 17, 2022Three kinds of materials are selected: basalt, glass fiber, and synthetic fiber, and each material includes two processing technologies: woven cloth and needled felt.

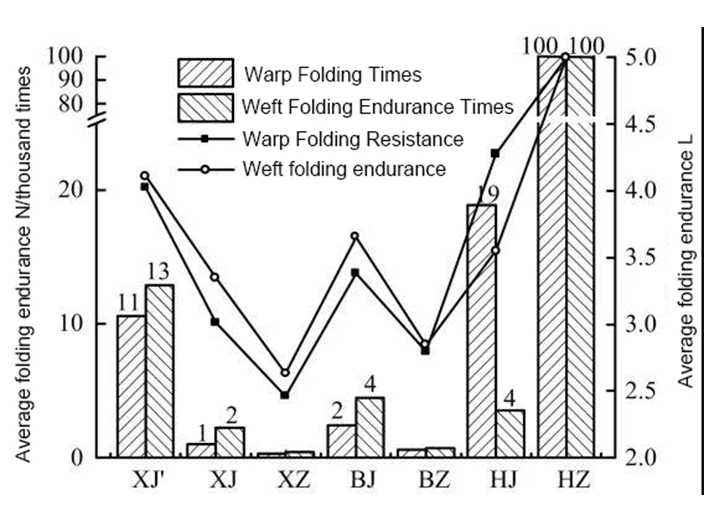

Basalt woven fabrics (including impregnation), needled felt and glass fiber woven fabrics, needled felts in the weft direction have better folding endurance than in the warp direction, while synthetic fiber woven fabrics are the opposite; The folding degree is preferred to that of the needled felt; on the contrary, the folding resistance of the synthetic fiber needled felt is far superior to that of the woven fabric; Its folding resistance is the best; the folding resistance of the basalt woven fabric after impregnation and modification is significantly improved than that of the plain fabric.

Among the similar materials such as basalt, glass fiber and synthetic fiber, the breaking strength of needled felt is slightly lower than that of woven fabric; basalt in woven fabric, especially after impregnation, has the largest breaking strength; glass fiber filter material in needled felt The breaking strength of the sample is slightly larger. The breaking strength of synthetic fiber woven fabric and needle-punched felt is small, and the elongation is large, which is reflected in higher toughness; while the breaking strength of basalt woven fabric is large, and the elongation and folding resistance are small, which is reflected in the comparison of brittleness. high.

With the deepening of my country's industrialization and urbanization, the pressure of air pollution prevention and control continues to increase. The State Council's Action Plan for the Prevention and Control of Air Pollution raises the pollutants characterized by the control of inhalable particulate matter (fine particulate matter) to an unprecedented height that will harm people's health and affect social harmony and stability. In order to implement the Action Plan for the Prevention and Control of Air Pollution, and In the whole society's action to eliminate smog, all walks of life will use more bag filters, and will also tap more high-performance fibers to deal with different complex working conditions in the non-electric field.

Basalt fiber is an inorganic high-temperature fiber material, which can be made from a single widely distributed ores such as basalt, diabase, amphibole, and perlite. Basalt fiber has strong adsorption capacity for asphalt, strong corrosion resistance, thermal insulation and sound insulation, high tensile and shear strength, large elastic modulus, good chemical stability, and has high adaptability in harsh environments. It has a wide temperature range and is one of the products that have been researched more in the bag filter industry in recent years.

It can be expected that in the next few years, the demand for bag-type dust removal equipment in the fields of electricity, cement, waste incineration, and steel will increase greatly, and bag-type dust removal technology will continue to make greater progress.