Nitrogen Oxide Denitrification Catalyst for Power Station SCR Catalyst

Product Description

Thereby reducing NOx emissions, and reducing smoke pollution to the environment. SCR denitration technology has become the mainstream technology of flue gas denitrification in the world.

At present, the commercial SCR catalysts are basically using TiO2 as base material and V2O5 as the main active ingredient, with WO3 and MoO3 as anti-oxidation and anti-poisoning auxiliary components.

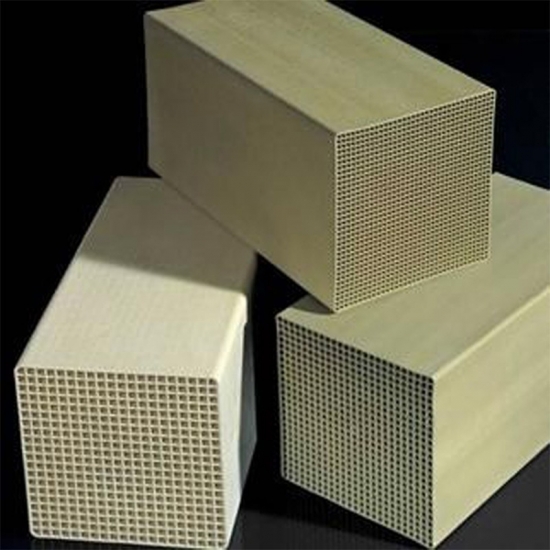

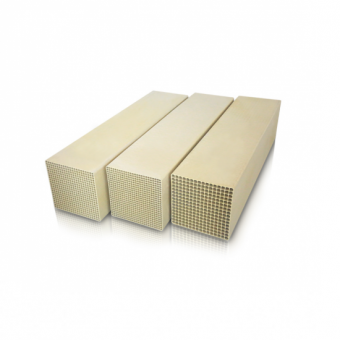

There are three types of SCR catalysts in the market, honeycomb catalyst, plate-types catalyst and corrugated catalyst. Commonly used is the honeycomb catalyst, plate-types catalyst. Honeycomb SCR catalyst is a porous honeycomb homogeneous product, its main backing material is TiO2, WO3, and V2O5and so on.

1).SCR technology is a recation at use of the denitration catalyst at a certain temperature(270-400 degree),that NOX in the flue gas mixed with ammonia gas from the reducing agent supply the system after the occurence of the selective catalytic reduction reaction of nitrogen and water ,thereby reducing NOX emissions , and reducing smoke pollution to the environment.

The chemical eauation for a selective catalytic reaction process is :

4NO+4NH3+O2→4N2+6H2O 6NO2+8NH3→7N2+12H20

NO+NO2+2NH3→2N2+3H20

2).At present, commercial SCR catalyst basically to TiO2 for the substrate to V2O5 as the main active ingredient in WO3, MoO3 for anti-oxidation, anti-drug of auxiliary ingredients.

3). Based on self-rennovation ,Yuanchen Continues to seek comprehensive cooperation with well known enterprises of advanced technolgy from both home and abroad . the company has cooperated with EE&E,G&G, NE ,CCIC on the advanced SCR technology in rent years, while established stable relationships with famous EPDIS power construction companies and equipments manufacturers as well.

4).High performance honeycomb SCR Catalyst features

a: high activity&NOX removal efficiency

b: low SO2 conversion rate

c:low NH3 slip

d: excellent resistance to posioning&abrasiom

e : high durability &stability

f: small volume ,high specific surface area,economical and practical.

5). the Capacity of our Production of Honeycomb SCR Catalyst of our company is8000m³/year.

Applications

SCR denitration catalyst belongs to high-tech products, mainly for the efficient denitration power plant flue gas, waste incineration of nitric acid tail gas industry and nitric acid plant, nitrate plant, steel plant, chemical fertilizer plant and other industries.

Principle: the catalyst at a certain temperature (200--400 °C), using ammonia as the reducing agent,take the advantage of the reducing agent selective, preferentially react with industrial emissions of nitrogen oxide, NOx catalytic reduction to nitrogen and water which no environmental pollution, has accelerated the catalytic role, to eliminate the purpose of NOx.

Main specifications & technical index of honeycomb SCR catalyst:

|

Hole Number (PCS) |

Cross Section (mm) |

Hole Dia. (mm) |

Wall Thickness (mm) |

Catalyst Pitch (mm) |

Open Porosity (%) |

Specific Surface Area (m2/m3) |

Applicable Scope |

|

15×15 |

150×150 |

8.45 |

1.35 |

9.80 |

71.40 |

338 |

Coal fired unit, high smoke dust |

|

16×16 |

150×150 |

8.00 |

1.20 |

9.20 |

72.82 |

383 |

|

|

18×18 |

150×150 |

7.10 |

1.10 |

8.20 |

72.60 |

409 |

Coal fired unit, medium dust |

|

20×20 |

150×150 |

6.40 |

1.00 |

7.40 |

72.82 |

469 |

|

|

21×21 |

150×150 |

6.10 |

0.95 |

7.05 |

72.93 |

478 |

Coal fired unit, low smoke dust |

|

22×22 |

150×150 |

5.80 |

0.90 |

6.70 |

72.36 |

499 |

|

|

25×25 |

150×150 |

5.00 |

0.90 |

5.90 |

69.44 |

577 |

Coal fired unit, very low dust |

|

30×30 |

150×150 |

4.10 |

0.80 |

4.90 |

67.24 |

693 |

Oil fired unit, very low dust |

|

35×35 |

150×150 |

3.65 |

0.55 |

4.20 |

72.53 |

795 |

|

|

40×40 |

150×150 |

3.20 |

0.50 |

3.70 |

72.82 |

910 |

Natural gas fired unit |

|

45×45 |

150×150 |

2.78 |

0.50 |

3.28 |

69.56 |

1000 |

|

|

55×55 |

150×150 |

2.20 |

0.50 |

2.70 |

65.07 |

1275 |

|

|

Unit catalyst size:150×150×(length300-1350) mm. |

|||||||

According to the customer's requirements, we can produce different pitch and formulations of honeycomb SCR de NOx catalyst.

How to react?

2 Designs for the place of SRC catalyst

The honeycomb SCR catalyst packaging

The catalyst is packed into an iron frame,then use pe bag packed in case into the damp

After Sale Service

1.OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry within 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

5.Quality Guarantee, If there have any quality problems with products, we are willing to be replaced free.

6.rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours.If any problem, We will arrange professional engineers within 48 working hours to solve it.

7. All goods will be inspected and tested before shipment.

Customer’s satisfactory is most important to us. If you have any problems about our products. Please feel free to contact us with any comments you may have;

FAQ

Q: Are you manufacturer or trading company?

A: We are the professional manufacturer and exporter, more than 16 years experience.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Anhui Province,3 hour by high speed rail from Shanghai.Warmly welcome to visit us anytime.

Q: How do you control the quality?

A: We insist "Quality First, Customer First", always pay attention to quality control from the beginning to the end,Alibaba Gold Supplier,TUV certification assigned by Made-in-China.

Q: How can I get the quotation?

A: Tell us the specifications, such as working situation, dust or fume characteristics, air volume(CFM), filter area(M2), inlet temperature(℃), wind speed(M/min) etc. We will send the quotation within 24 hours.

Q: How to pay for the product?

A: T/T, L/C, Western Union, Paypal are available.

Q: How long is the delivery time?

A: About 5-40 days upon the payment.

Q: How about the after-sale installation of dust collector?

A: 1.We provide installation manual, technical consulting forever. Our engineers are available to help you install dust collector onsite.

2.We also can provide installing turn-key projects overseas.