Application of denitration catalyst in biomass boiler

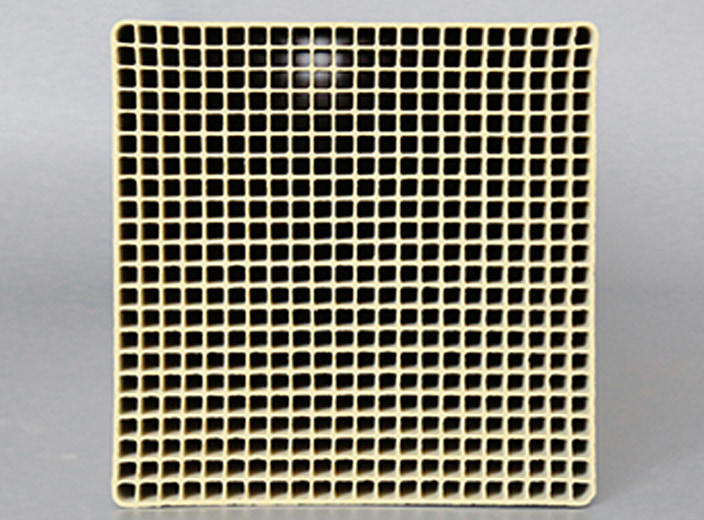

Jan 19, 2022The main characteristics of the flue gas used by denitration catalysts are: ① the furnace temperature difference is large, ② the content of hydrogen in the biomass is high, and ④ the concentration of sulfur dioxide and nitrogen oxides is low and the fluctuation is large. Sparks are harmful to SCR catalysts. The current SNCR denitrification technology can meet the standard of 200mg/Nm3 of NOx content in the outlet exhaust gas. Now the biomass boiler emission standard is implemented according to the emission standard of the thermal power industry, and the NOx emission is required to be 100 mg/Nm3 or even lower to 50 mg/Nm3, so biomass boilers It is imperative to upgrade boilers to add desulfurization and SCR denitration devices.

Comparison of Biomass Boiler Tail Gas Denitrification Processes

The denitrification process currently used is mainly to transform the boiler, take gas from the outlet of the economizer at 200~240 °C, and then enter the SCR denitration system after dry desulfurization and dust removal. The temperature of the flue gas after passing through the dust removal and denitration system is generally around 30 °C, which wastes a lot of energy and increases the operating cost.

Anhui Yuanchen Environmental Protection Science and Technology Co., Ltd. ("Yuanchen Technology" for short) is a high-tech enterprise integrating R&D, production and sales of dust removal bags and denitration catalysts. Dust filter bags (mainly PPS, PTFE, P84 and composite series filter materials) and SCR denitration catalysts have been widely used in cement, steel, glass furnaces, waste incineration power generation, biomass power generation, non-ferrous metal smelting and other industries! In the future, Yuanchen Technology will be guided by "becoming a guardian of the global ecological environment", always take root in environmental protection, and adhere to the great cause of protecting the blue sky and white clouds. Leveraging the national ecological civilization construction pattern, we will continue to deepen technology, optimize management, strengthen brands, refine industries, consolidate advantages, and create synergistic value for the industry through comprehensive overall management and services.