3 High Temperature Filter Cloth Fiber

Jul 16, 20211.PPS Fiber

Chemical structure: polyphenylene sulfide.

The fiber has excellent acid and alkali resistance and good wear resistance. The fiber working temperature is 130-170 ° C, the general continuous use temperature is 160 degrees or less, the short-time working temperature is 190 ° C, and the melting point is 285 ° C. It is also the core material of PPS Filter Bag.

In normal use, the oxygen content should be less than 8%. The higher the oxygen content, the lower the use temperature.

Oxidation resistance is poor; generally requires oxygen content within 10%, and oxygen content decreases with increasing temperature.

PPS is a white material with excellent thermal stability. Although it will be burned when it is placed in a flame, once the flame is removed, the combustion will stop immediately, burning a yellow-orange flame and generating a trace of black soot. The combustibles do not fall off, forming residual coke, exhibiting lower flame retardancy and smoke density. The limiting oxygen index is 34-35. Polyphenylene sulfide fiber fabric can be exposed to an acidic environment for a long time and can be used in a high temperature environment. It is one of the few fibers that can withstand abrasion and has high filtration efficiency.

Temperature resistance: working temperature 130 ~ 170 ° C, short-term working temperature 190 ° C, melting point 285 ° C.

Corrosion resistance: It can resist most of the acidic substances except strong oxidizing acids (such as concentrated nitric acid, concentrated sulfuric acid and chromic acid). It is also very resistant to the corrosion of strong alkali. In addition to toluene in organic solvents, other Common organic solvent species also have little effect on its strength.

Oxidation resistance: Poor, strong degradation occurs in strong oxidants, and this decomposition rate accelerates as the temperature of use increases.

The textile performance is better, and a higher strength fabric can be obtained.

Therefore, the actual conditions such as temperature, oxygen, bromine and nitrogen dioxide must be known as much as possible when selecting the filter.

2.Nomex Fiber

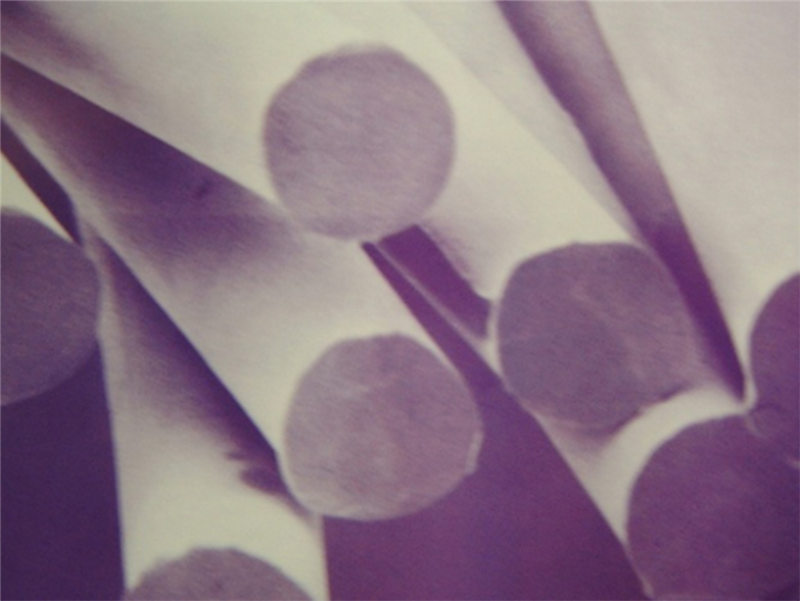

Nomex fiber has excellent wear resistance and good temperature resistance. It has a continuous temperature resistance of 204 degrees and an instant of 230 degrees. It is a non-heat shrinkable fiber.

The hydrolysis resistance is general, so the chemical treatment of the fiber is required during use.

Nomex fiber is a meta-aromatic polyamide fiber that can withstand temperatures below 2000C under dry conditions. We can use it to make Nonwoven Nomex filter bag. Hydrolysis occurs when there is moisture and chemicals. Nomex fiber is a polycondensation polymer like polyester that will hydrolyze and only withstand much higher temperatures. Nomex is a filter used in high temperature applications where polyester can be brittle and fail.

Nomex's resistance to flexing and abrasion is excellent and is better than most synthetic fibers. Nomex fibers are non-thermoplastic and cannot be glazed, but special techniques can be used for singeing or other post-treatment.

3.P84 Fiber

Chemical characteristics: The chemical structure of P84 is: polyimide. It has excellent resistance to sulfur oxides and nitrogen oxides, and has good alkali resistance. It is suitable for use in acid and alkali rot.

Temperature characteristics: P84 is sensitive to temperature and generally requires operation at temperatures between 150 and 260 degrees Celsius.

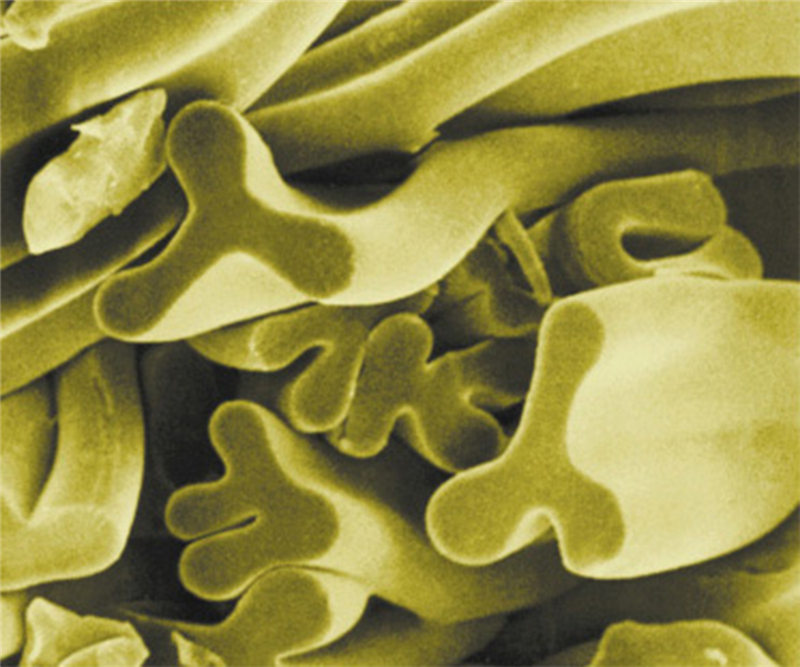

Structural features: Trilobal structure, large specific surface area, wear resistance, high filtration efficiency.

P84 has excellent heat resistance, non-melting polymer, glass transition temperature of 315 degrees, and fiberization begins to charcoal at more than 310 degrees, due to the inherent non-flammable properties of aromatic structural polymers and fibers. The limiting oxygen index can be measured to be 38, which can even be used for temperatures above 260 degrees depending on the environment.

(1) Chemical resistance

P84 is relatively stable and resistant to most common organic solutions such as alcohol and halogenated hydrocarbons or ethers. However, for strong polarity, solvents such as dimethylformamide and dimethylacetamide are relatively sensitive. P84 is also sensitive to strong oxidants such as nitrogen dioxide at elevated temperatures. Strong acids such as hydrochloric acid, sulfuric acid and zinc-containing chlorides affect P84.

(2) Fiber morphology: The fiber is yellow in color and has a trilobal cross section, which greatly increases the surface area of the fiber under the premise of the same weight and linear density, and is more advantageous for intercepting dust during the filtration process.